A hollow-core photonic crystal fiber coupler

A hollow-core photonic crystal and fiber coupler technology, applied in the field of fiber couplers, can solve problems such as poor stability and mechanical properties, large polarization-related loss, complicated manufacturing process, etc., and achieve small additional loss, large return loss, and reflection. The effect of low loss and polarization dependent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the drawings and embodiments.

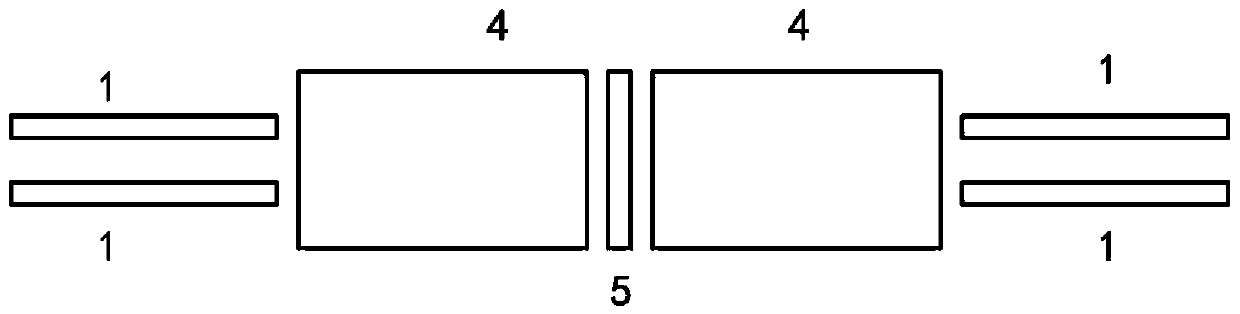

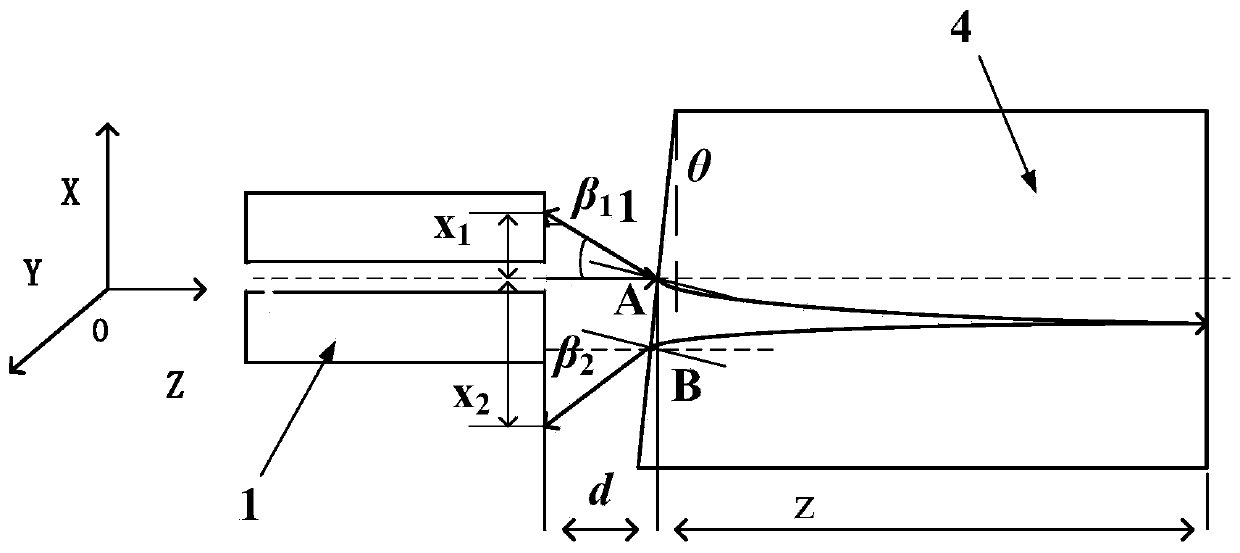

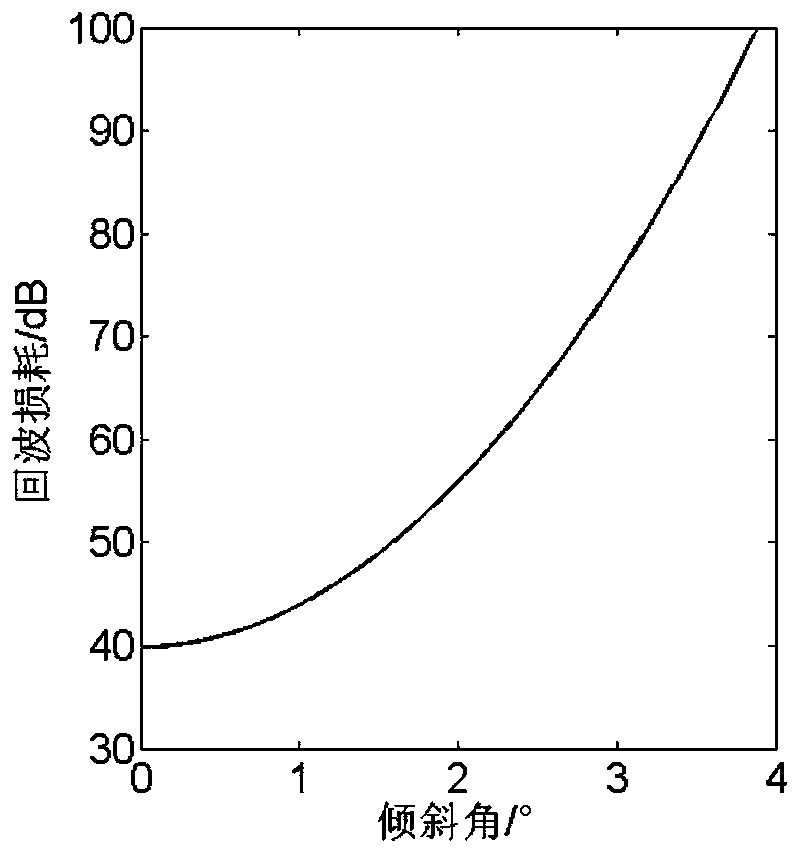

[0023] The invention provides a hollow-core photonic crystal fiber coupler, such as figure 1 As shown, the hollow-core photonic crystal fiber coupler is composed of two dual-fiber collimators and a reflective film 5. The dual-fiber collimator is composed of two hollow-core photonic crystal fibers 1 and a GRIN lens 4. A reflective film 5 with a certain reflectivity is inserted between the two dual-fiber collimators according to the requirements of the splitting ratio. figure 1 The optical path shown is arranged in sequence with the first dual-fiber collimator, the reflective film 5, and the second dual-fiber collimator to form a complete hollow-core photonic crystal fiber coupler. The distance d between the pigtail of the hollow core photonic crystal fiber 1 and the center of the front end face of the GRIN lens 4 is between 0.2 and 0.3 mm, the tilt angle of the G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com