A kind of virtual reality eyepiece design and manufacturing method

A manufacturing method and technology of eyepieces, applied in magnifying glass, optics, instruments, etc., can solve the problems of increased field curvature and coma, dizziness of inconsistent users, etc., to reduce field curvature and coma, improve imaging quality, The effect of thinning the center thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

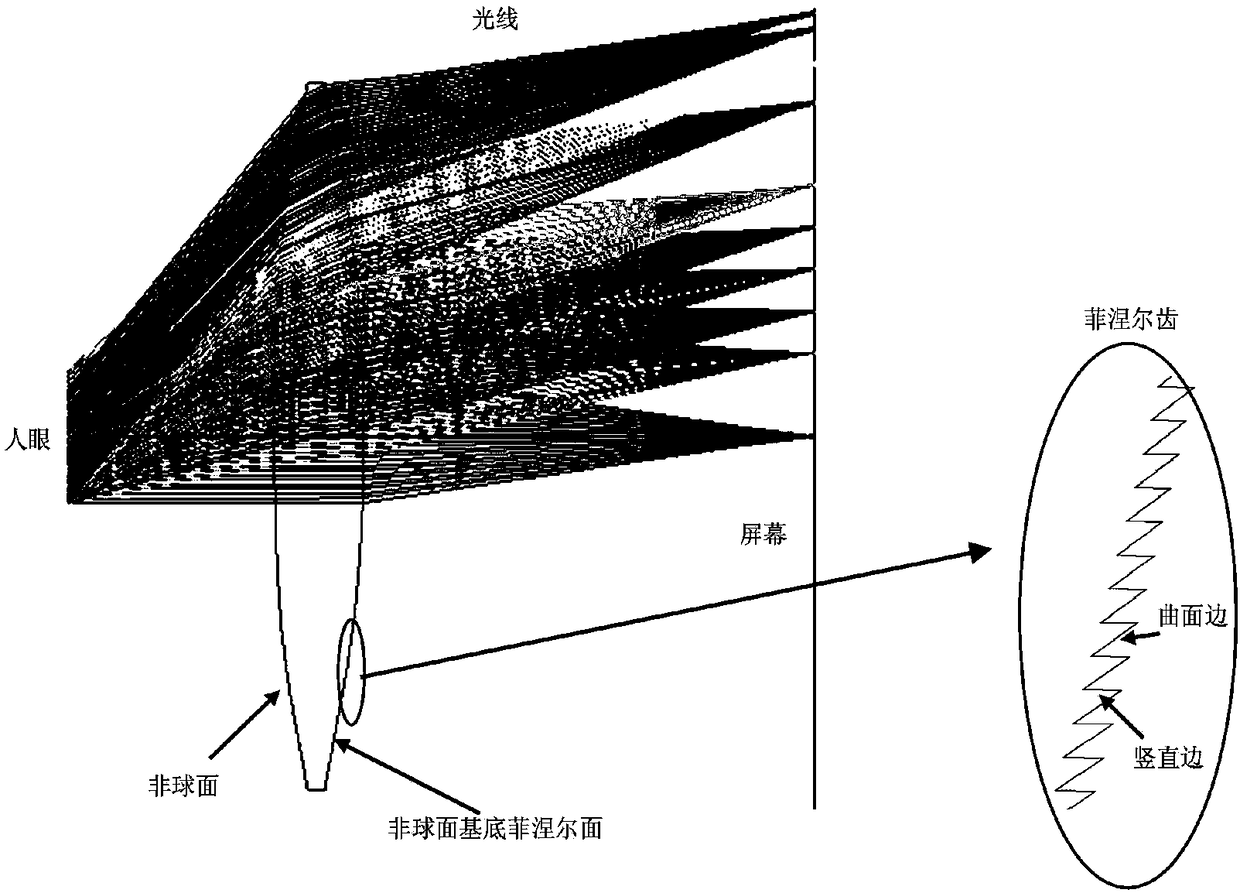

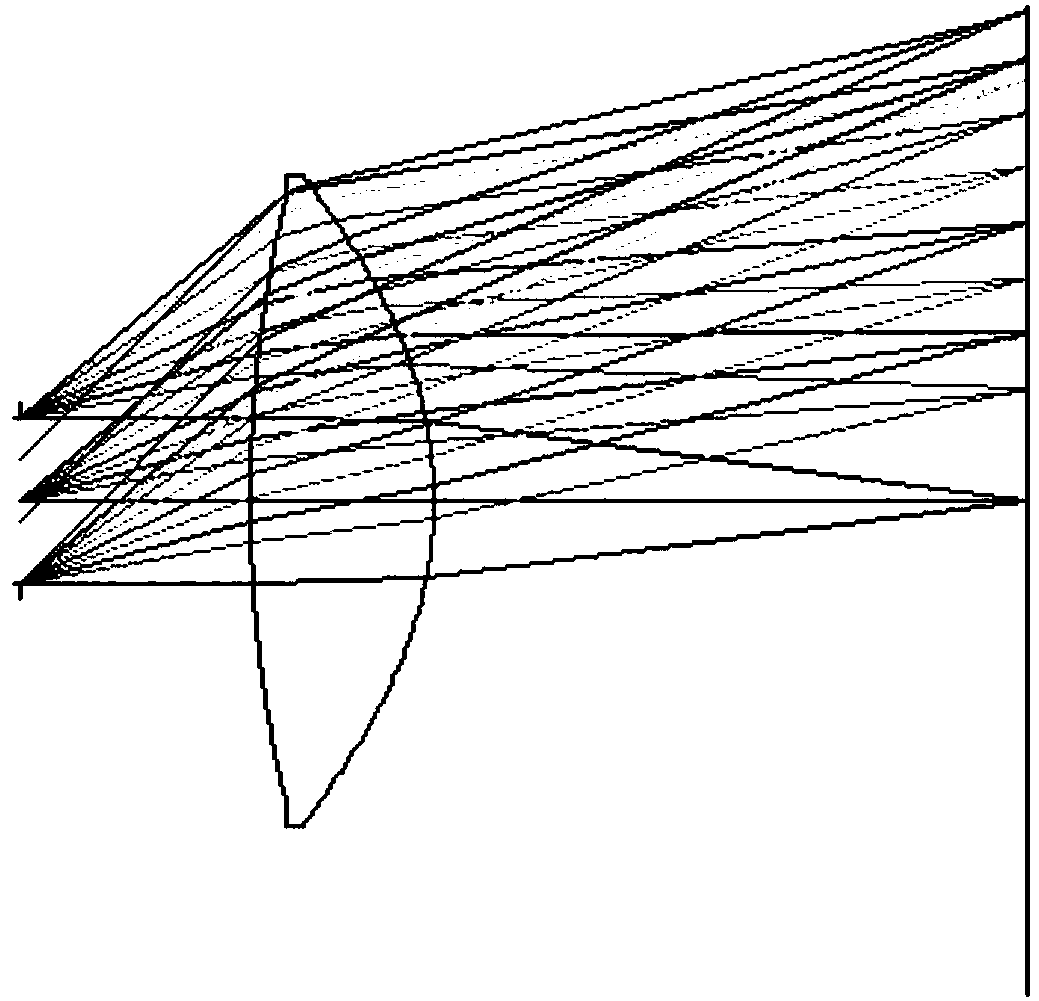

[0027] The imaging principle of VR eyepieces is that the light emitted by the pixels on the screen passes through the eyepieces and enters the human eye in parallel. When the human eye observes at the exit pupil position, it is equivalent to the image on the screen at infinity. The images observed by the left and right eyes come from two screens respectively, which produces a 3D visual effect. If the edge field curvature and coma of the system are too large, the sharpness of the edge imaging and the center imaging will be inconsistent, and the user will be dizzy during the use of VR glasses, thus losing the meaning of the large field of view. The present invention proposes an aspherical base Fresnel eyepiece design, which can greatly reduce field curvature and coma caused by a large field of view.

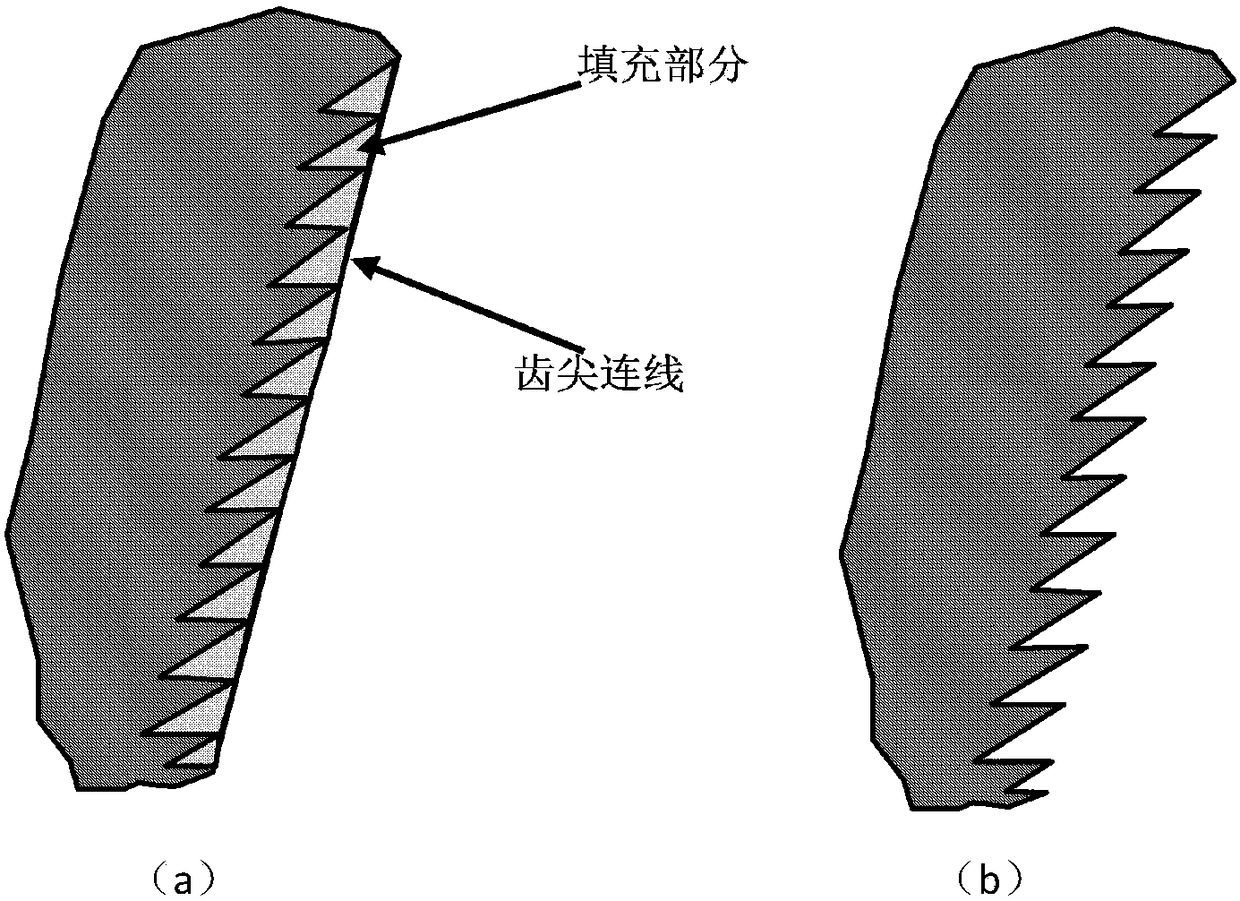

[0028] The specific structure of the present invention is as figure 1 As shown, the aspherical design of the VR lens is superimposed on one aspherical surface or two aspherical surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com