Preparation method of silver behenate and direct thermal imaging recording material prepared through silver behenate

A technology of silver behenate and recording material, applied in photosensitive materials, photothermographic systems, optics, etc., can solve the problem of high use cost, and achieve the effects of safe use environment, cost reduction, and harm reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

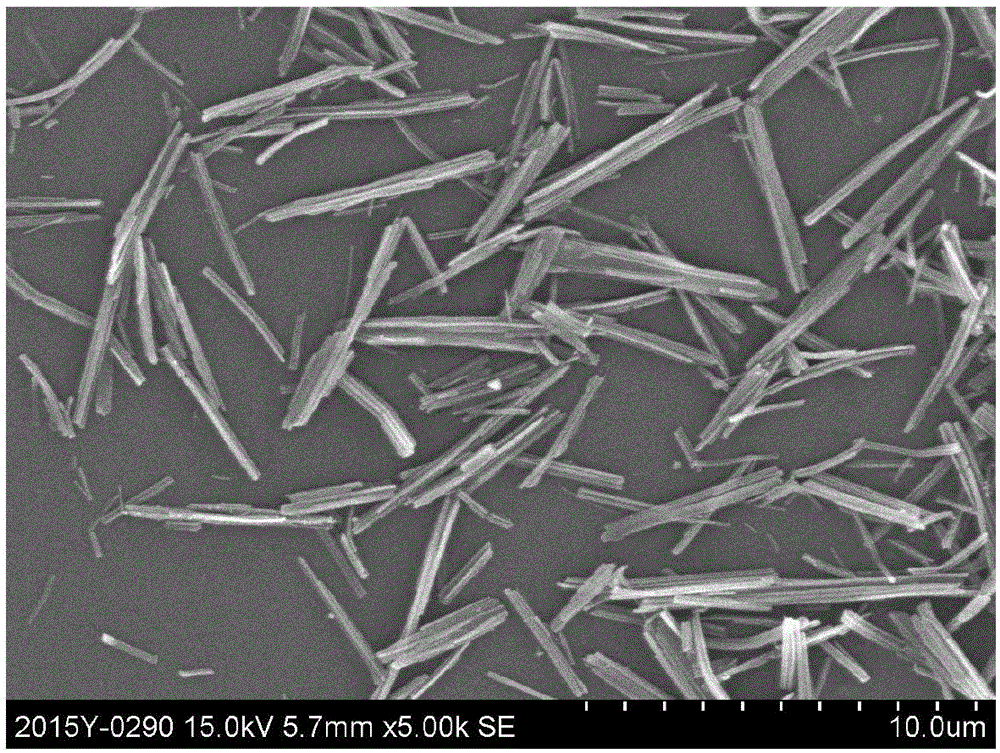

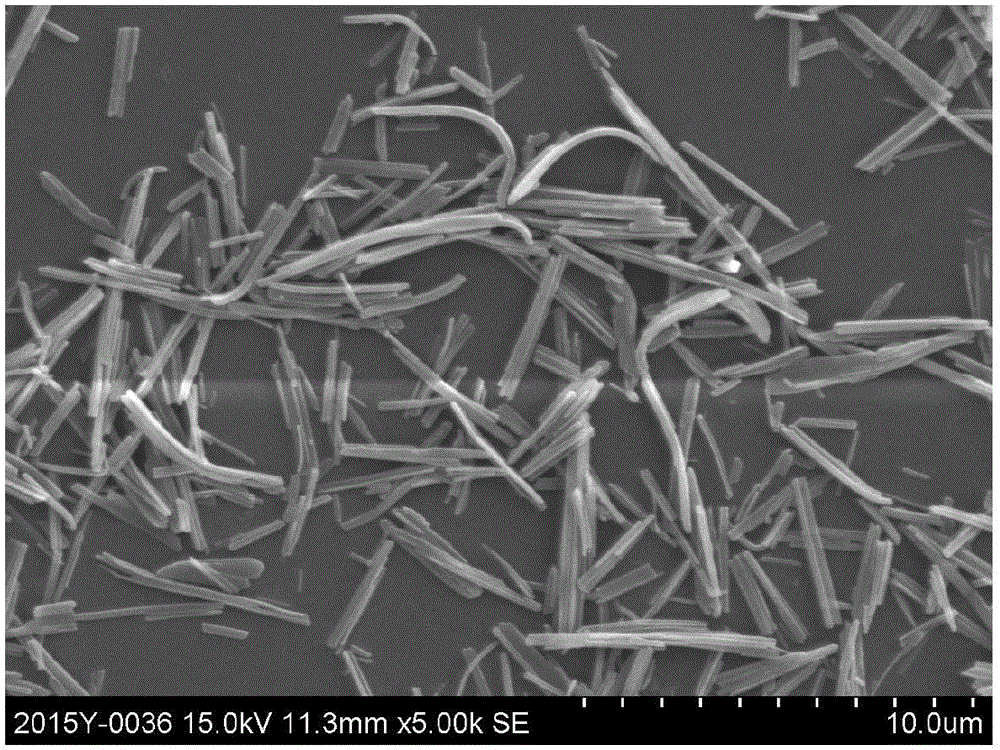

Image

Examples

preparation example Construction

[0037] A preparation method for silver behenate, comprising the following steps:

[0038] (1) Add behenic acid, water and alcohol into the reactor, heat and dissolve until transparent, then add sodium hydroxide, completely dissolve until transparent, and obtain solution A;

[0039] (2) Silver nitrate is added to A and emulsified to obtain a silver behenate suspension B;

[0040] (3) the silver behenate suspension B is washed with water until the conductivity of the silver behenate suspension is less than 20 us / m to obtain a silver behenate wet cake;

[0041] (4) Drying the washed silver behenate wet cake until the weight does not change any more to obtain silver behenate powder.

[0042] The method for preparing a direct thermal imaging recording material using the above-mentioned silver behenate comprises the following steps:

[0043] (1) Silver behenate pre-dispersion: Dissolve PVB in ethyl acetate, add silver behenate dry powder, and stir at room temperature for pre-dispe...

Embodiment 1

[0102] (1) Preparation of silver behenate: 115.2g of behenic acid, 2000g of water and 880g of n-amyl alcohol are added to the reactor, heated to 75°C until completely dissolved to a transparent state, and then 345.6g of sodium hydroxide solution ( Concentration 5%), dissolve completely to transparent state, obtain solution A; 69.12g silver nitrate is added in A and carry out emulsification, obtain silver behenate suspension B;

[0103] (2) Washing and drying of silver behenate: wash the obtained silver behenate suspension with deionized water until the conductivity is 5us / m; dry at 60°C until the weight does not change; obtain silver behenate powder X1 .

Embodiment 2

[0105] (1) Preparation of silver behenate: 157.3g of behenic acid, 2000g of water and 360g of isoamyl alcohol were added to the reactor, heated to 75°C until all dissolved to a transparent state, and then 314.6g of sodium hydroxide solution was added ( Concentration 5%), dissolve completely to transparent state, obtain solution A2; 70.8g silver nitrate is added in A2 and carry out emulsification, obtain silver behenate suspension B2;

[0106] (2) Washing and drying of silver behenate: wash the obtained silver behenate suspension B2 with deionized water until the conductivity is 1us / m; dry at 60°C until the weight does not change; obtain silver behenate powder X2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com