Internal series capacitance element of power capacitor

A technology for power capacitors and capacitive elements, applied to fixed capacitor electrodes, components of fixed capacitors, and dielectrics of fixed capacitors, etc., can solve the problems of increasing labor costs and increasing the difficulty of processing capacitive elements, reducing processing costs and reducing the number of components. , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

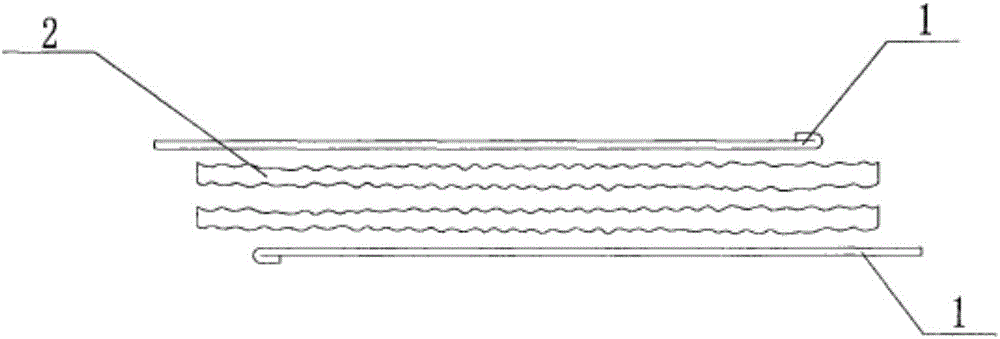

[0028] This example provides an internal series capacitance element of a power capacitor, including: a first pole plate 1, an insulating film 2, at least one intermediate pole plate 3 and a second pole plate 4; the first pole plate 1 and the second pole plate 4 At least one intermediate pole plate 3 is arranged between them, an insulating film 2 is provided between the first pole plate 1 and the middle pole plate 3, between the middle pole plates 3, and between the second pole plate 4 and the middle pole plate 3 .

[0029] The middle pole plate 3 is the common pole plate of the first pole plate 1 and the second pole plate 4, the first pole plate 1 and the second pole plate 4 form an inner series capacitance element through the middle pole plate 3, and the first pole plate 1 One side longer than the edge of the insulating film 2 and the second pole plate 4 are used as the lead-out pole of the internal series capacitor element.

[0030] The middle pole plate 3 in this example i...

Embodiment 2

[0035] Based on Embodiment 1, the inner series capacitor element provided in this example includes two intermediate plates 3 to realize the inner three-string capacitor element, and the inner three-string capacitor element realizes the merging of the external three series elements. Electrical connection diagram as Figure 6 shown.

[0036] The structural diagram of the inner three-series capacitor element is as follows Figure 7 As shown, the difference with the inner two-series capacitive element of Embodiment 1 is that: the common two middle pole plates 3 between the first pole plate 1 and the second pole plate 4, and the two middle pole plates 3 Two layers of insulating film 2 are placed between them; the placement and shape requirements of the first pole plate 1 and the second pole plate 4 are the same as those in the first embodiment, please refer to the first embodiment for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com