Height-adjustable wafer bearing mechanism

An adjustable and height-adjustable technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of non-adjustable wafer support mechanism, etc., and achieve the effect of simple structure, safe and reliable positioning accuracy, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

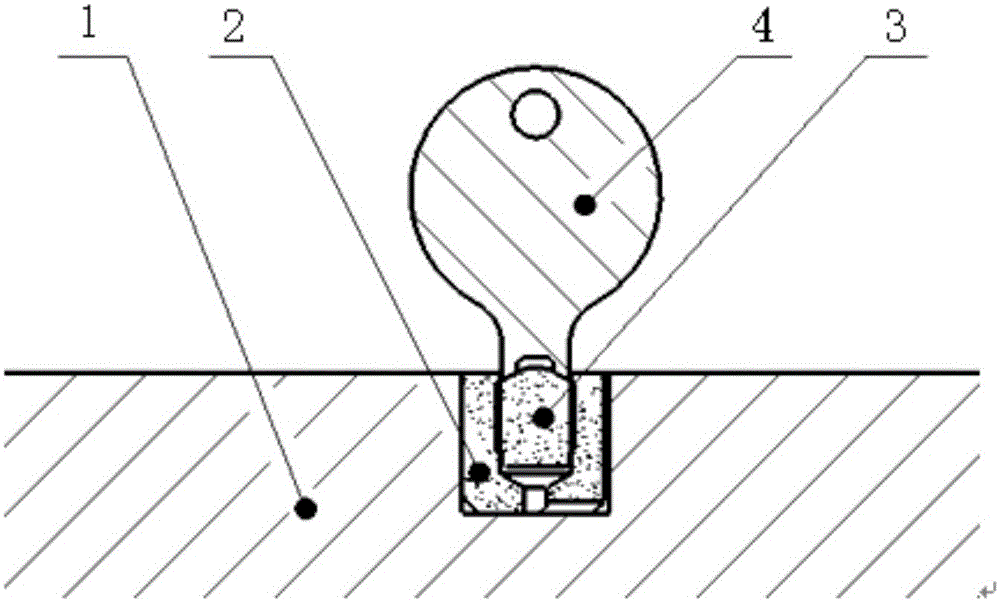

[0014] refer to figure 1 , a height-adjustable wafer support mechanism, including a hot plate 1, a ceramic sleeve 2, a ceramic column 3 and an adjustment wrench 4. The ceramic column 3 is formed with external threads; the ceramic sleeve 2 is formed with internal threads, and the ceramic sleeve 2 is threadedly connected with the ceramic column 3 .

[0015] The above-mentioned hot plate 1 is processed with a circular counterbore, and the ceramic sleeve 2 is put into the counterbore, and then the ceramic column 3 is screwed into the ceramic sleeve 2 with an adjustment wrench 4 . The top of the ceramic column 3 is shaped with a spherical protrusion, which matches the concave surface at the bottom of the adjustment wrench 4 .

[0016] The spherical protrusion at the top of the ceramic column 3 is used to support the wafer, the height between the spherical protrusion of the ceramic column 3 and the upper surface of the hot plate 1 is measured with a height gauge, and the adjustment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com