Lithium battery module and block structure of lithium battery module

A group structure, lithium battery technology, applied in small-sized batteries/battery packs, large-sized batteries/battery packs, battery pack components, etc., can solve the problems of inconvenient secondary use of 18650 cells and achieve The effect of compact structure, high reliability and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

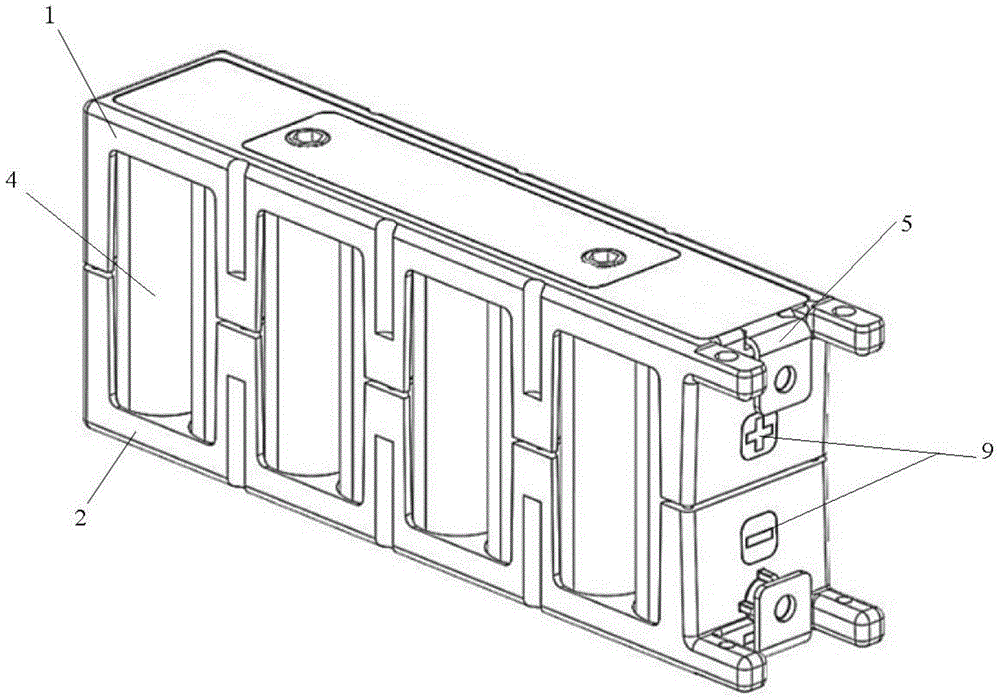

[0028] Such as figure 1 and figure 2 As shown, this embodiment provides a lithium battery module, figure 1 The overall appearance of the lithium battery module is shown. The two inner hexagonal holes seen from the top are used to pass through the connecting rods when the lithium battery membrane blocks are grouped. The terminals are bent and embedded in the plastic casing with nuts to facilitate external wiring.

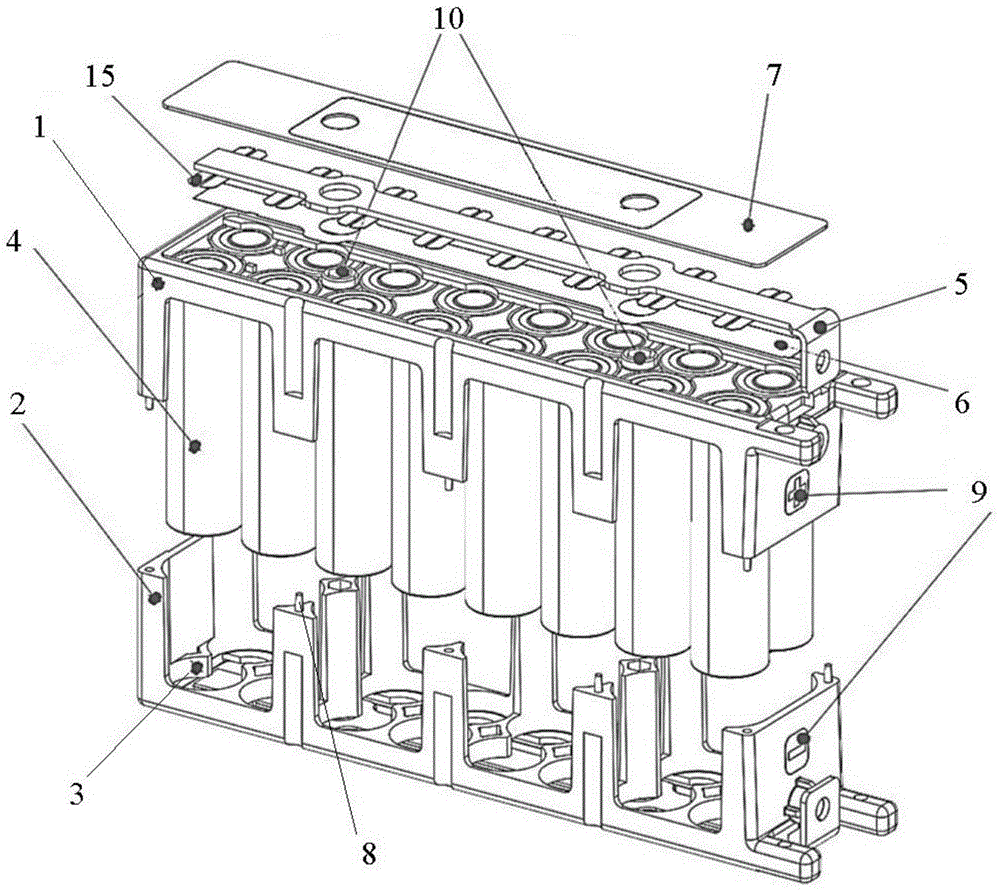

[0029] figure 2 The detailed structure of the lithium battery module is shown, including: a lithium battery cell; a plastic casing, the plastic casing is composed of an upper casing 1 and a lower casing 2, and four fixed lithium batteries are arranged inside the upper casing 1 and the lower casing 2. The slot 3 of the battery cell 4; two busbars 5, on which the nickel sheet 15 is spot-welded, the nickel sheet 15 is welded to the positive and negative poles of the lithium battery cell 4, and one end of the busbar 5 faces the plastic shell The side wall of the bu...

Embodiment 2

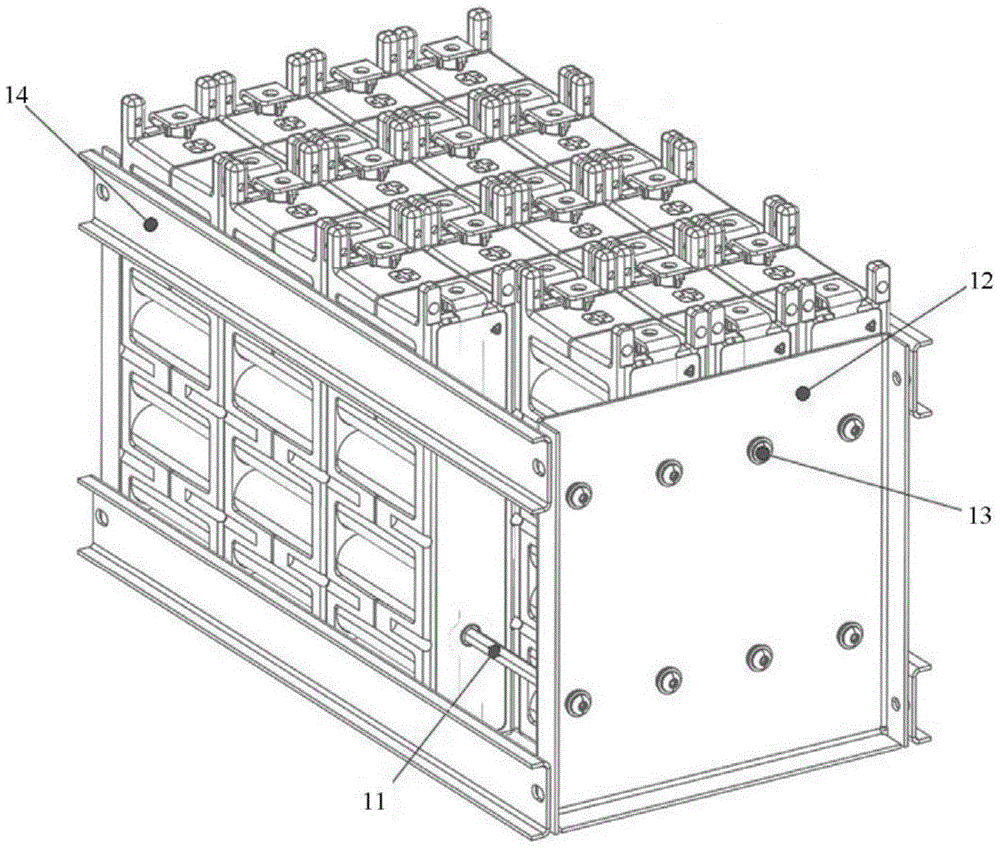

[0036] image 3 An example of the detailed structure of a 4×4 group of lithium battery modules is shown (one module is removed so that the internal structure can be seen clearly). Including 16 lithium battery modules with the same structure, the lithium battery modules are fixedly connected through the hexagonal stud connecting rod 11 passing through the hole column to form a larger lithium battery module, the hexagonal stud connecting rod 11 passes through the end plate 12, and passes through the The fastener 13 installed at the end of the connecting rod is fixed on the end plate 12, so that 16 lithium battery modules form a larger lithium battery module.

[0037] Both ends of the reinforcing beam 14 are fixedly connected to the end plate 12 respectively, and the reinforcing beam 14 is connected to the end plate 12 to increase the stiffness of the large module in the y direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com