Charging and capacity rating method for bare cells of polymer lithium batteries

A process method and bare cell technology, applied in the field of lithium battery production, can solve problems such as low efficiency, waste of manpower, material and financial resources, prolonged production cycle, etc., to improve labor efficiency, reduce turnover costs, and improve cell quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

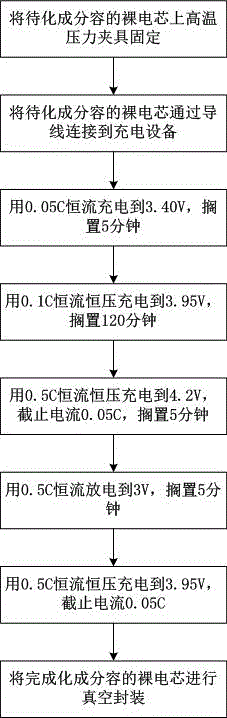

[0019] Such as figure 1 Shown, a kind of polymer lithium battery bare cell composition capacity process method, it comprises the following steps:

[0020] S01: Fix the high-temperature pressure fixture on the bare cell to be converted into capacity;

[0021] S02: Connect the bare cell to be converted into capacity to the charging device through a wire;

[0022] S03: Charge to 3.40V with 0.05C constant current, and leave it for 5 minutes;

[0023] S04: Charge to 3.95V with 0.1C constant current and constant voltage, and leave it for 120 minutes;

[0024] S05: Charge to 4.2V with 0.5C constant current and constant voltage, cut-off current 0.05C, leave for 5 minutes;

[0025] S06: Discharge to 3V with a constant current of 0.5C, and leave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com