Lithium ion laminated battery manufacturing device and manufacturing method

A manufacturing device and lithium-ion technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, and final products, can solve problems such as difficult grasping and difficult positioning accuracy, and achieve improved production efficiency, good performance, and stacking positioning high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with accompanying drawing:

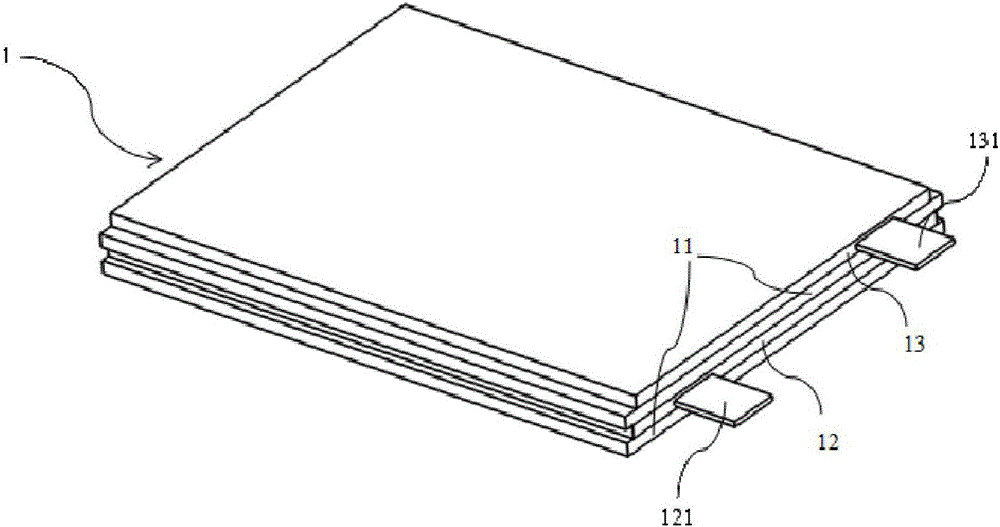

[0058] figure 1 A three-dimensional structural schematic diagram of a four-layer unit 1 of a lithium-ion laminated battery in the present invention is shown. The four-layer unit 1 is formed by thermally compounding after the diaphragm 11-negative electrode sheet 12-diaphragm 11-positive electrode sheet 13 is laminated, wherein the negative electrode sheet 12 has a negative tab 121, and the positive tab 13 has a positive tab 131. Since the separator 11, the negative electrode sheet 12, and the positive electrode sheet 13 have different sizes, the centers of the negative electrode sheet 12 and the positive electrode sheet 13 must be kept aligned when stacking the sheets.

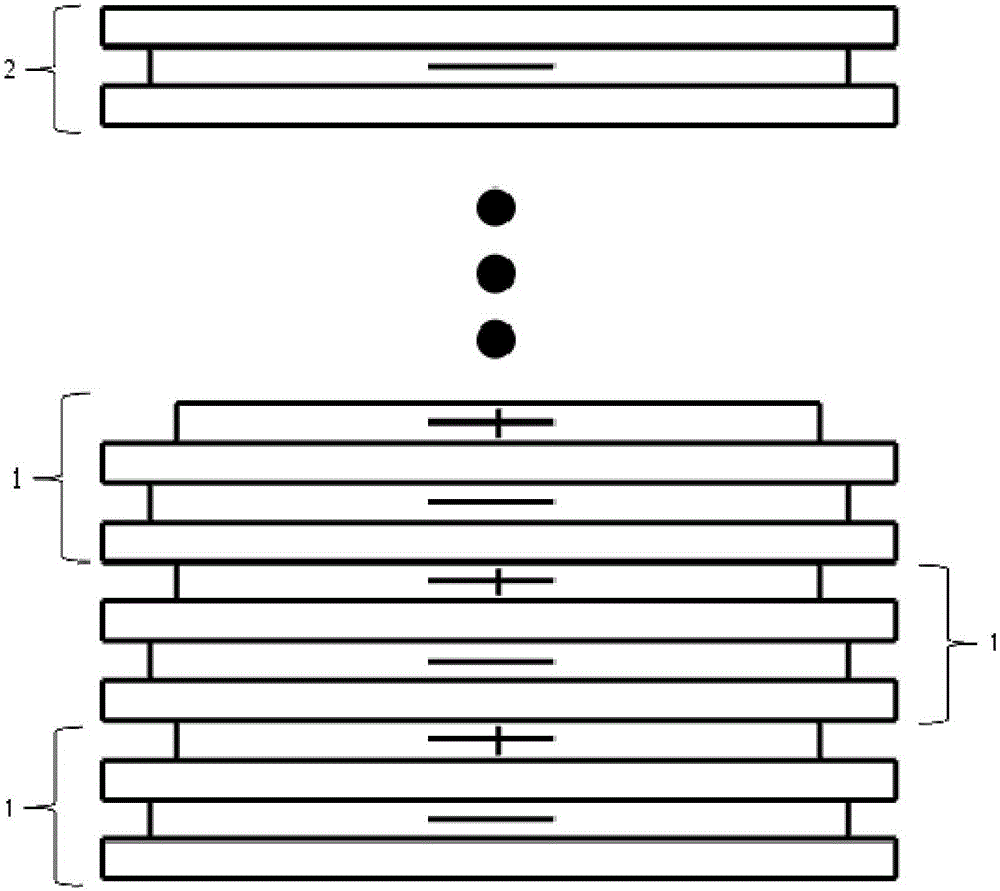

[0059] figure 2 It is a schematic diagram of the structure of lithium-ion laminated battery cells in the present invention. The cells of laminated batteries are composed of several four-layer units 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com