Lipid-lowering health piece with garlicin and preparing method thereof

A technology of allicin and health care tablets, which is applied to the functions of food ingredients, polysaccharide/gum-containing food ingredients, food extraction, etc., can solve the problems of limited development of garlic deep-processing health products, lack of garlic processing technology, etc., and achieve good market development prospects , good formability, and the effect of improving blood lipid metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

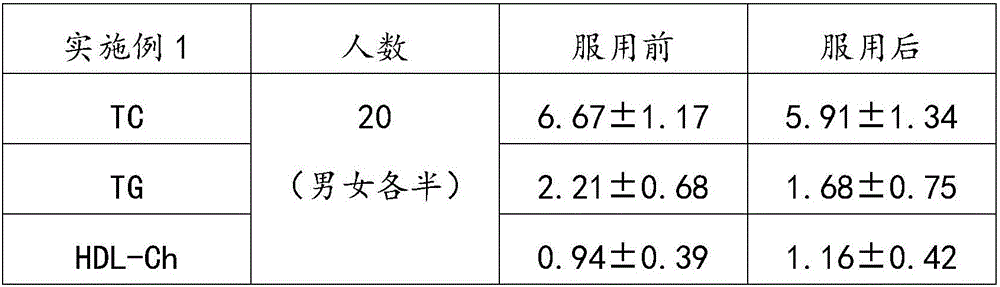

Embodiment 1

[0043] S10, take by weighing 300g of allicin, 280g of ginkgo biloba extract, 150g of carboxymethyl chitosan and 10g of vitamin E that have passed the quality inspection, and place them in a mixer and mix for 30min;

[0044] S20, weigh 60g of maltodextrin, suspend with a small amount of cold water and then dilute with boiling water, stir evenly to form a mixed slurry with a concentration of 10%, and then add it to the mixture in step S10 to make the mixture stick together to make soft material;

[0045] S30, put the soft material processed in step S20 into a swinging granulator to make wet granules, then transfer it to a drying room through a turnover box, and transfer it to a rotary tablet press when it is dried until the moisture content is less than 5%. Compressed into tablets, and finally packed into packaging jars or bags.

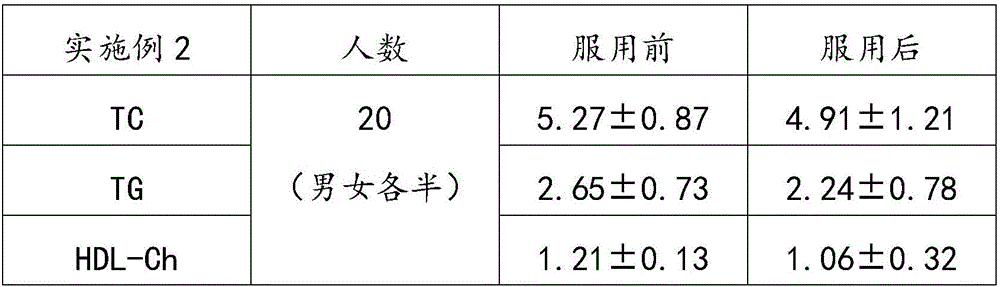

Embodiment 2

[0047] S10, take by weighing 500g of allicin, 350g of ginkgo biloba extract, 100g of carboxymethyl chitosan and 20g of vitamin E that have passed the quality inspection, and place them in a mixer and mix for 20min;

[0048] S20, weigh 30g of maltodextrin, suspend with a small amount of cold water and then dilute with boiling water, stir evenly to form a mixed slurry with a concentration of 10%, then add it to the mixture in step S10 to make the mixture stick together to make soft material;

[0049] S30, put the soft material processed in step S20 into a swinging granulator to make wet granules, then transfer it to a drying room through a turnover box, and transfer it to a rotary tablet press when it is dried until the moisture content is less than 5%. Compressed into tablets, and finally packed into packaging jars or bags.

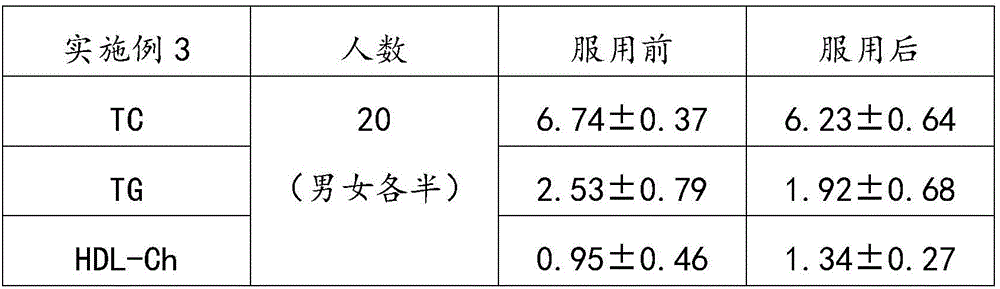

Embodiment 3

[0051] S10, take by weighing 600g of allicin, 300g of ginkgo biloba extract, 250g of carboxymethyl chitosan and 30g of vitamin E that have passed the quality inspection, and place them in a mixer and mix for 20min;

[0052] S20, weigh 20g of maltodextrin, suspend it with a small amount of cold water and dilute it with boiling water, stir evenly to form a mixed slurry with a concentration of 10%, then add it to the mixture in step S10 to make the mixture stick together to make soft material;

[0053] S30, put the soft material processed in step S20 into a swinging granulator to make wet granules, then transfer it to a drying room through a turnover box, and transfer it to a rotary tablet press when it is dried until the moisture content is less than 5%. Compressed into tablets, and finally packed into packaging jars or bags.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com