Liquid drop discharging apparatus and liquid drop discharging method

A discharge device, droplet technology, applied to the surface coating liquid device, spray device, coating, etc., can solve the problem of positional relationship changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

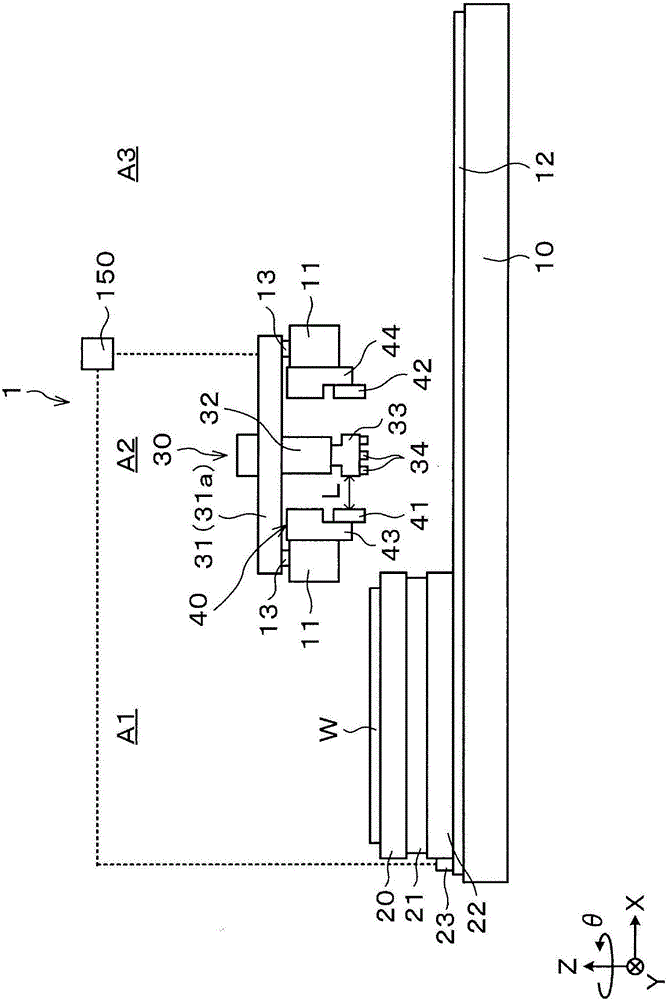

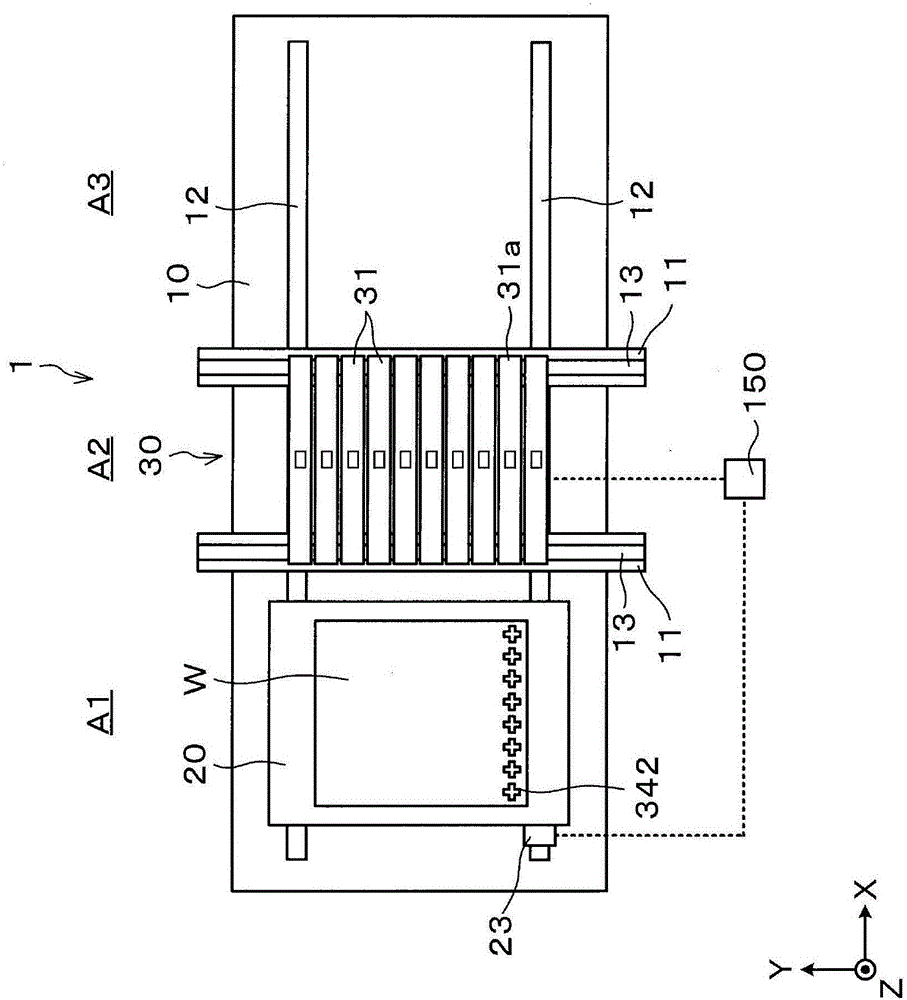

[0036] First, refer to figure 1 and figure 2 The configuration of the droplet discharge device according to the first embodiment of the present invention will be described. figure 1 It is a schematic side view showing a schematic configuration of the droplet ejection device 1 . figure 2 It is a schematic plan view showing a schematic configuration of the droplet ejection device 1 . In addition, in the following, let the main scanning direction of the workpiece W be the X-axis direction, the sub-scanning direction perpendicular to the main scanning direction be the Y-axis direction, and the vertical direction perpendicular to the X-axis direction and the Y-axis direction be the Z-axis direction. , The direction of rotation around the Z-axis direction is the θ direction.

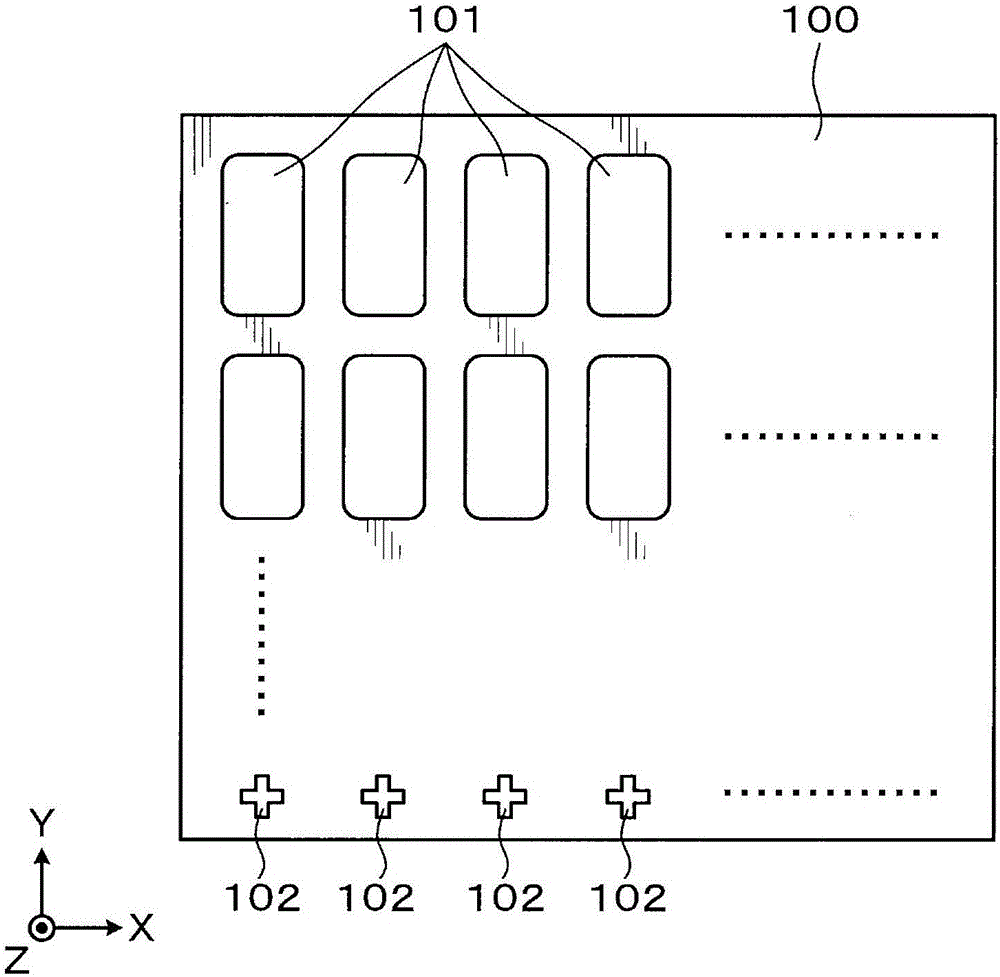

[0037] In addition, the workpiece W used in the present invention, such as image 3 As shown, a dike portion 100 is formed as a partition wall. The bank portion 100 is patterned into a predetermined pat...

Embodiment approach

[0079] According to the above-mentioned first embodiment, it includes: the movement amount detection mechanism 23 that detects the movement amount of the workpiece mounting table 20 in the X-axis direction (main scanning direction); The first imaging unit 41 of the captured image F; the image processing unit 160 that detects the reference mark 102 based on the captured image F; Therefore, in the workpiece movement control unit 162, the difference between the detected position of the reference mark 102 and the position of the reference mark 102 estimated by the mark position estimation unit 161 can be obtained. Then, in the workpiece movement control unit 162, if the difference is equal to or greater than a threshold value, it is determined that the position of the reference mark 102 detected at the imaging position deviates from the position of the reference mark 102 estimated by the mark position estimation unit 161. For example, The operation of the workpiece mounting table ...

no. 2 Embodiment approach

[0089] Next, a second embodiment of the present invention will be described. In addition, the droplet discharge device 1 used in the second embodiment is the same as the droplet discharge device 1 used in the first embodiment.

[0090] In the first embodiment, the position of the reference mark 102 of the workpiece W is detected, and so-called feedforward control is performed on the same workpiece W based on the position information of the reference mark 102. A case where the trend of deviation is common among workpieces. In this case, for example, correction data obtained when processing the K-th (K is a positive integer) workpiece W may be reflected in the processing of the K+1-th workpiece W. FIG.

[0091] Specifically, such as Figure 12 As shown, in the workpiece movement control unit 162 , before processing the K+1-th workpiece W, the correction position of the K-th workpiece W is collected in advance. In addition, in Figure 12 In , the offset in the Kth workpiece W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com