An intelligent processing system

An intelligent processing and intelligent technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of increasing production cost, assembly difficulty, affecting processing accuracy and processing strength, etc., to improve processing effect, reduce The possibility of deformation and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

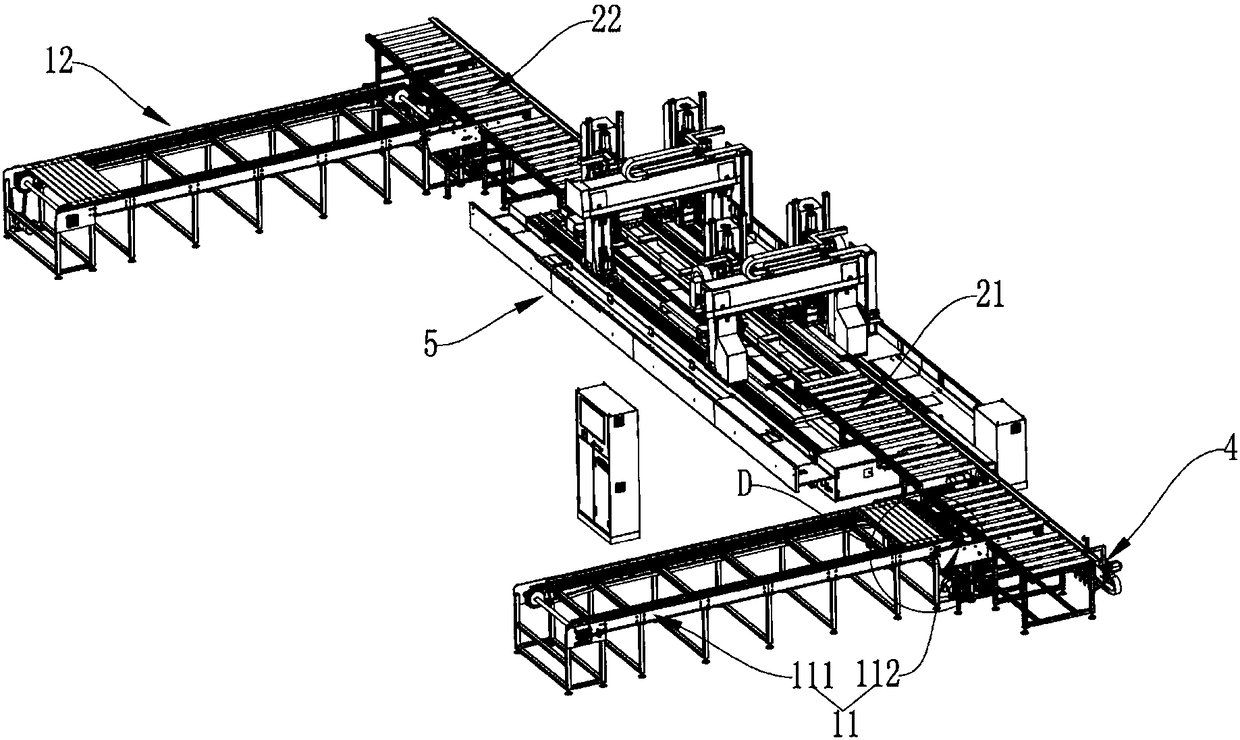

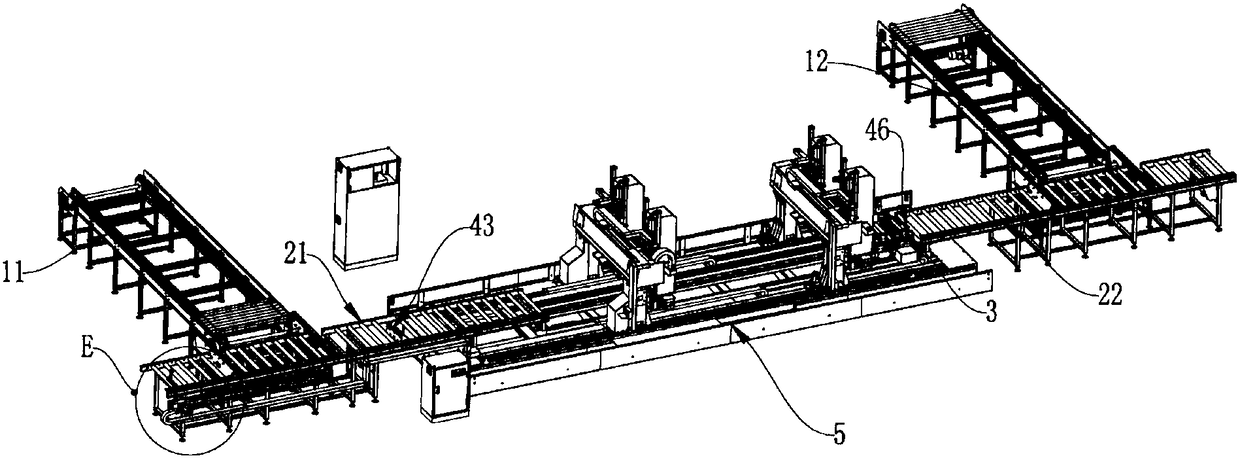

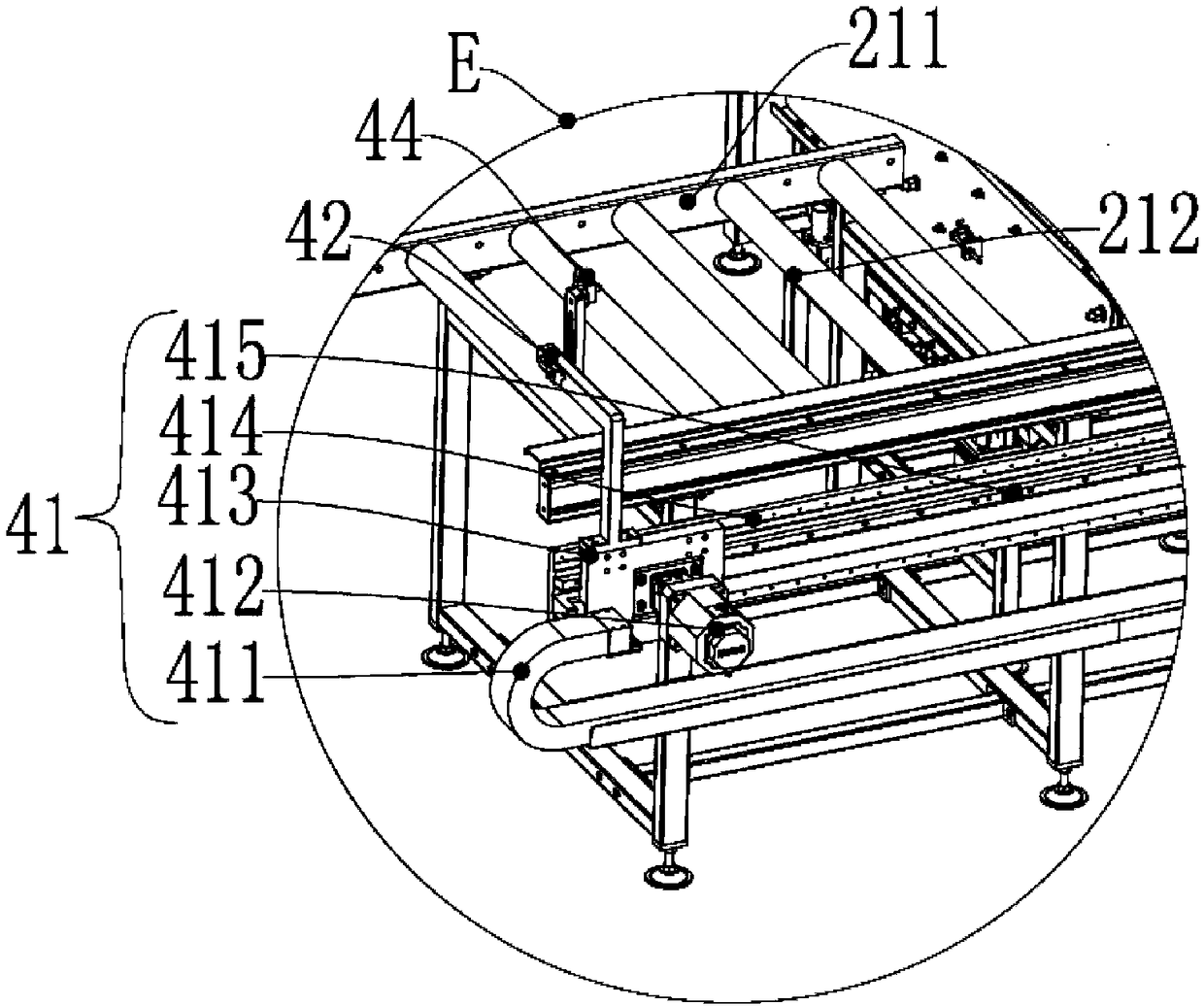

[0088] An intelligent processing system, comprising a feeding device 11, a feeding device 12, a first conveying device 21, a second conveying device 22, an intelligent fixture device, a workpiece length measuring device 4 and a processing machine tool 5;

[0089] The first conveying device 21 and the second conveying device 22 are respectively arranged at both ends of the processing machine tool 5;

[0090] The intelligent fixture device is installed on the processing machine tool 5;

[0091] The intelligent clamp device includes at least two sets of clamps 3, and the clamps 3 can move along the X-axis direction, so that the distance between each of the clamps 3 can be relatively close or relatively far away;

[0092] The workpiece length measuring device 4 is arranged on one side of the first conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com