Cutter internally provided with chip for service life statistics and cutter service life statistics method

A cutting tool and chip technology, which is applied in the direction of broaches, manufacturing tools, components with teeth, etc., can solve the problems of different service life of tooth rubbing tools, and the service life cannot be counted, and achieve simple statistics, simple structure and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

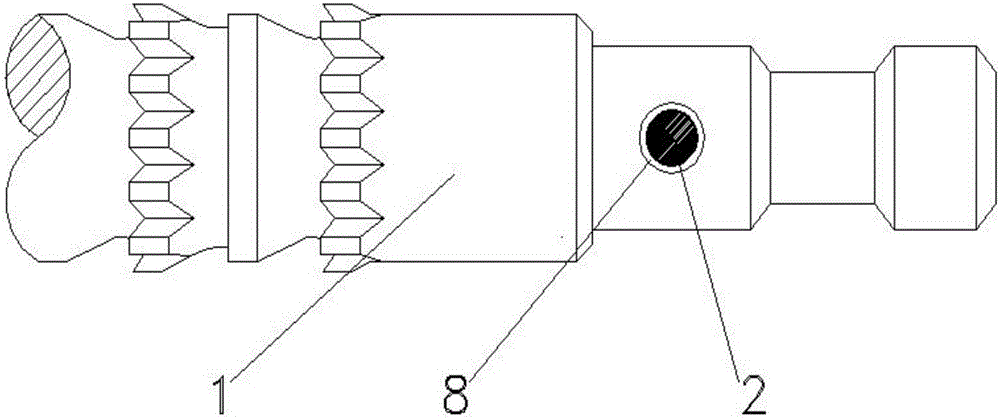

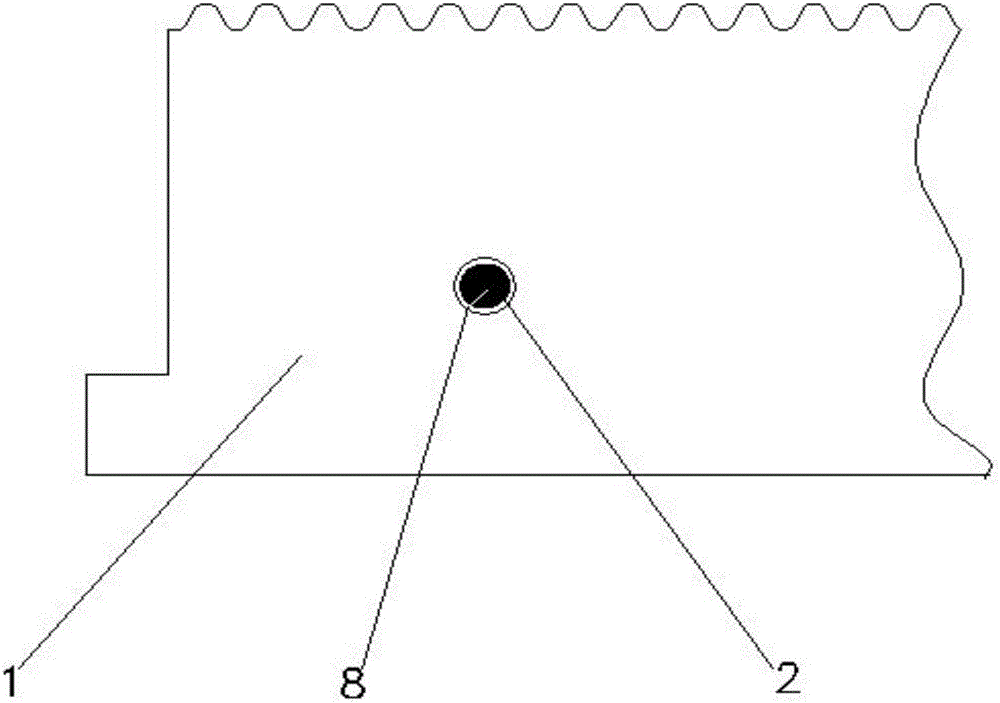

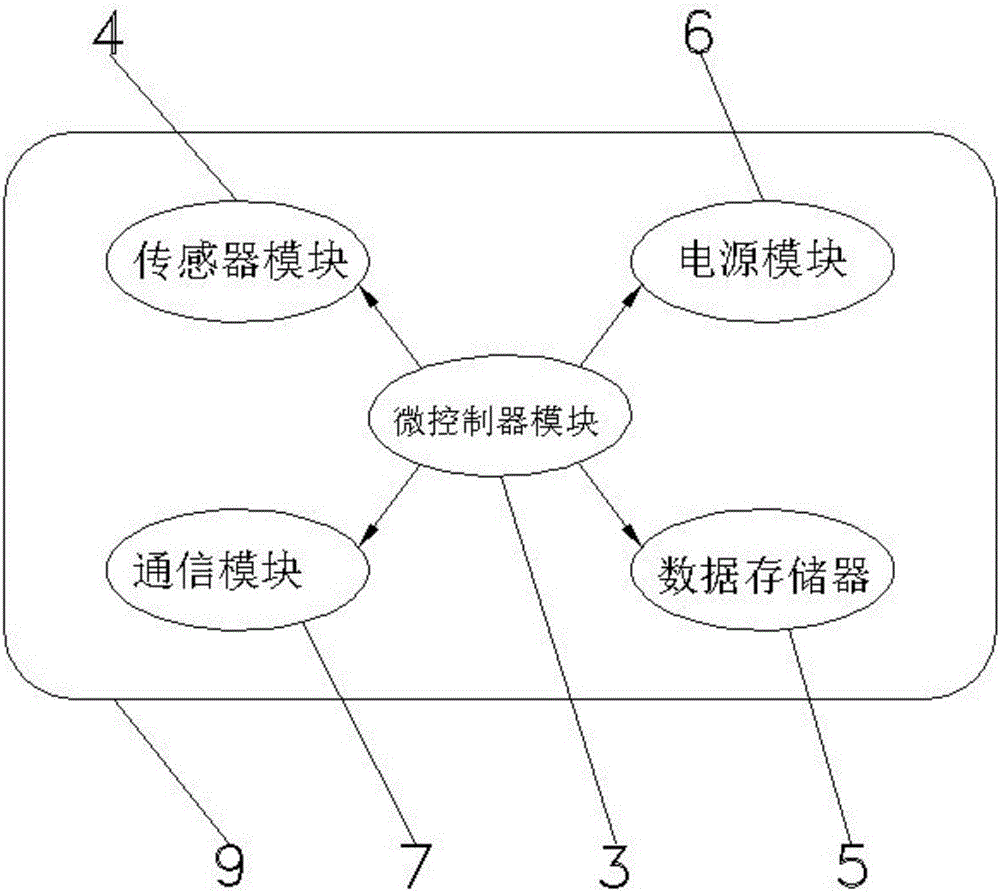

[0027] Example 1. A cutting tool with a built-in life statistics chip, which is composed of figure 1 , figure 2 and image 3 As shown, the cutter body 1 is included, and the cutter body 1 is provided with a chipset 2, and the chipset 2 includes a microcontroller module 3, and the software in the microcontroller module 3 adopts a low-power processing method, and the microcontroller module 3 are respectively connected with sensor module 4, data memory 5 and power module 6, and power module 6 provides energy for the entire chipset 2. The microcontroller module 3 is also connected with a communication module 7 capable of connecting with the outside world. The tool body 1 is provided with a chip slot 8 , which is designed in the non-working area of the tool body 1 , and the chip group 2 is fixed in the chip slot 8 . The chipset 2 is fixed in the chip groove 8 by epoxy resin. The tool body 1 is a broaching tool body or a gear rubbing tool body. The tool body 1 is made of hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com