Polishing machine with circulating discharging device

A technology of polishing machine and circular transmission, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., and can solve problems such as complex structure, easy failure, and high price of automatic polishing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

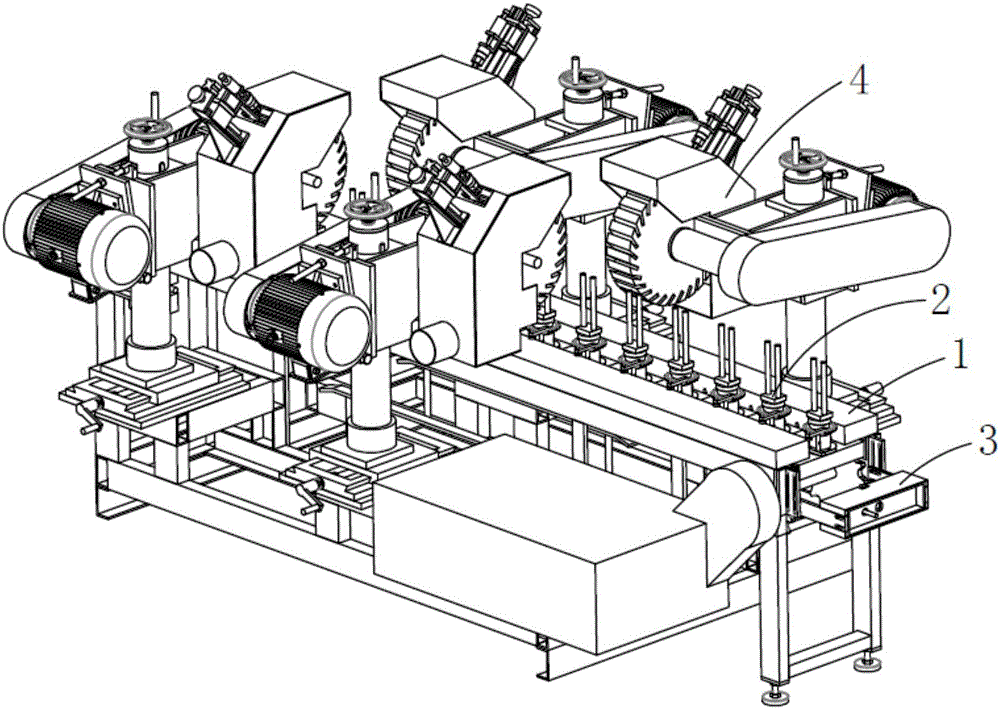

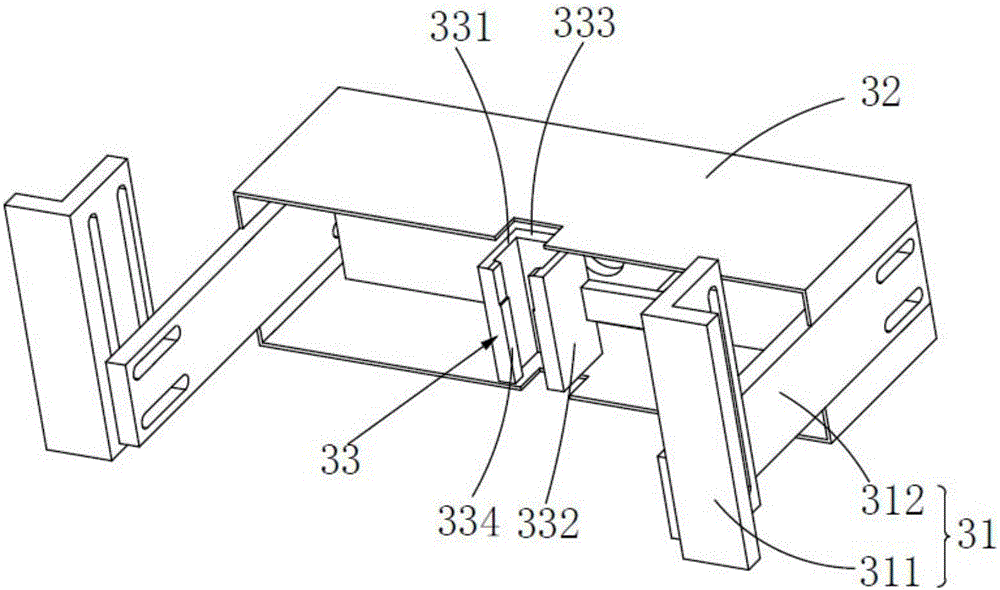

[0021] Example, see Figure 1 to Figure 2 As shown, a polishing machine with a circulating unloading device includes a frame 1 and a circulating conveyor chain, including a frame 1 and a circulating conveyor chain connected in a closed loop. A number of racks are installed on the circulating conveyor chain. 2. The circulating conveyor chain is installed in the middle of the frame 1. The circulating conveyor chain forms an upper conveyor chain and a lower return chain on the frame 1. The lower return chain is located below the upper conveyor chain. The frame 1 is fixed with several groups of polishing devices 4. The polishing devices 4 are distributed on both sides of the upper conveyor chain. Along the conveying direction of the circulating conveyor chain, a circulating unloading device 3 is provided at the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com