Multi-shaft and multi-nozzle 3D printer

A 3D printer and multi-nozzle technology, applied in the field of 3D printing, can solve the problems of slow printing speed and low precision, and achieve the effect of reducing printing time, improving work efficiency, increasing speed and printing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

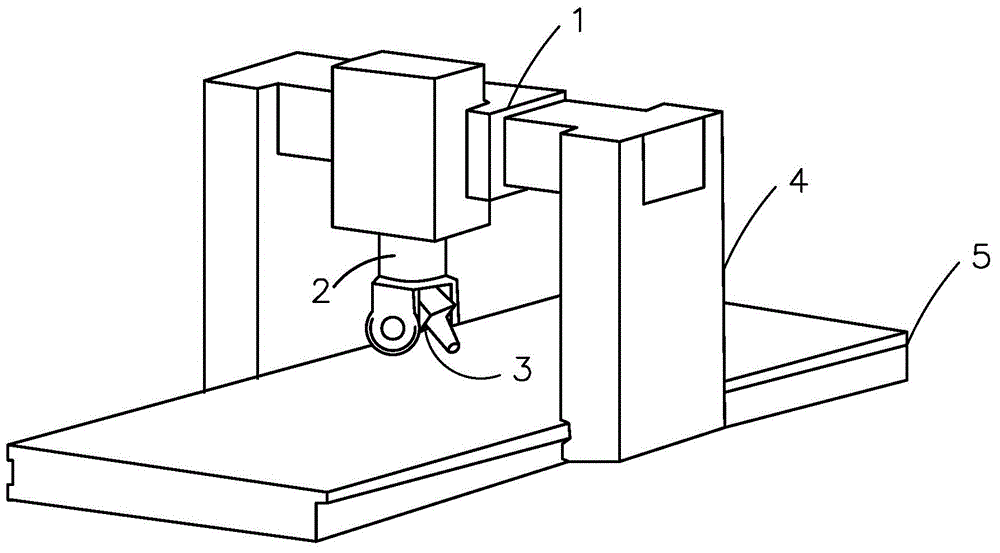

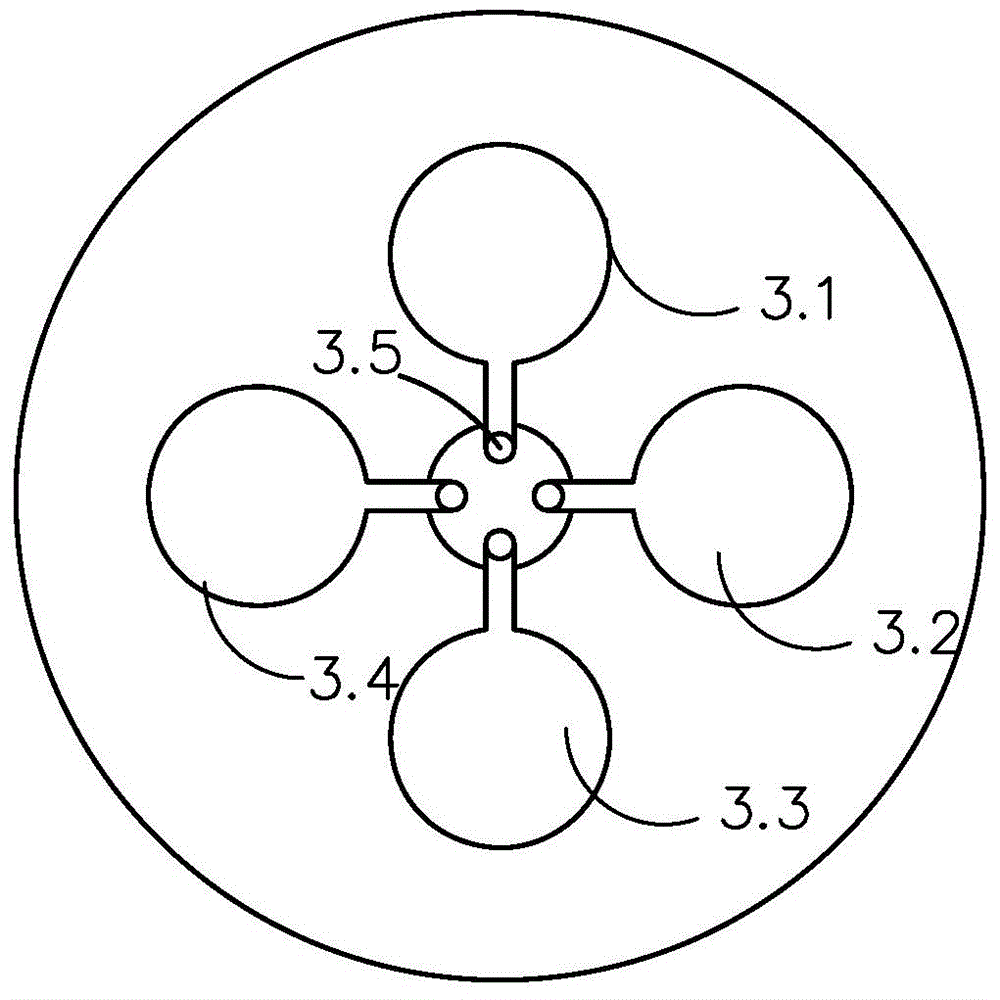

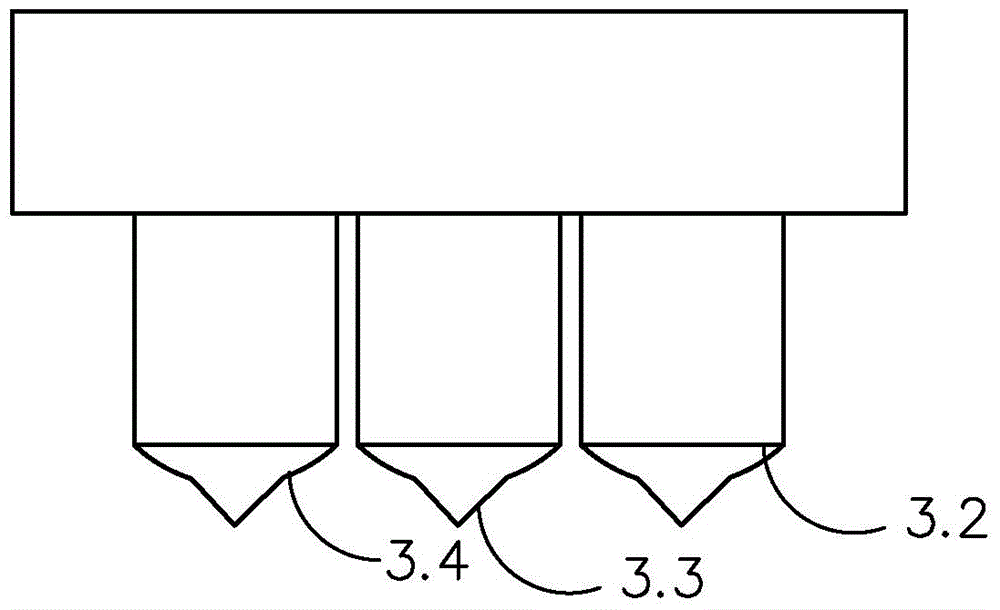

[0027] Such as figure 1 Shown, a kind of multi-axis multi-nozzle 3D printer comprises shaft I 1, shaft II 2, gun head 3, support 4 and workbench 5; said support 4 is movably installed on workbench 5; said support 4 is horizontal Shaft I 1 is provided; shaft II 2 is provided on shaft I 1; a gun head 3 is provided at the lower end of shaft II 2, and the gun head 3 is connected with the lower end of shaft II 2 through a rotating shaft, and the gun head 3 is evenly There are four nozzles 3.1; the outlets of the nozzles 3.1 are all aimed at one point. The axes I 1 and II 2 of the 3D printer move cooperatively through the control program system. The shaft II 2 is a vertical telescopic rod, which is convenient for the upper gun head 3 to move up and down. The table top of described workbench 5 is provided with heat-absorbing material, guarantees a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com