Continuous and automatic glue dipping and leaching production method for recombinant material and assembly line equipment for continuous and automatic glue dipping and leaching production method

A production method and technology of recombined wood, applied in wood impregnation, lighting and heating equipment, impregnated wood, etc., can solve the problems of high labor cost, low production efficiency, and poor automation, so as to reduce labor cost and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

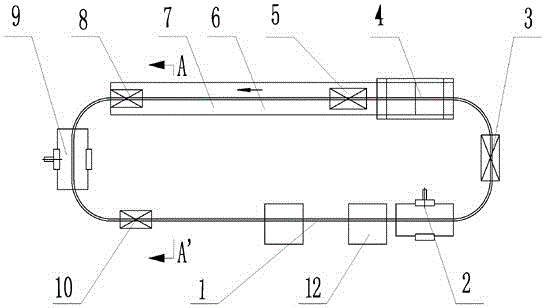

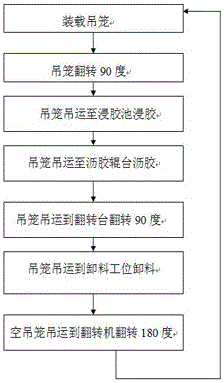

[0029] A method for continuously and automatically leaching and leaching glue for heavy wood, the method comprising the following steps:

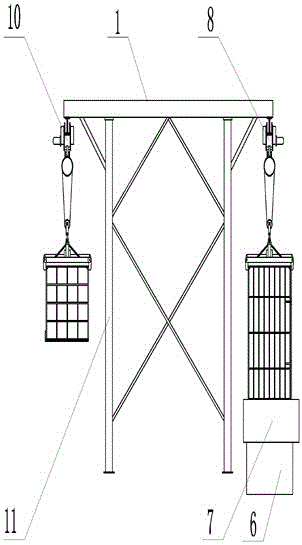

[0030] (1) Hanging cage loading and turning 90 degrees: the empty hanging cage 11 is placed on the first turning machine 2 and lies flat, so that the hanging cage

[0031] The cage opening door 111 faces upwards, and under the drive of the hydraulic working cylinder 202, the turning arm 203 of the turning machine rotates and opens and closes, and lifts up to open the cage opening door 111, as Figure 5 shown. After the dried bamboo or wood wool is covered with the hanging cage, the rotating arm 203 descends to close the opening door 111 and compress it under the action of the working oil cylinder 203. The first turning machine 2 turns the hanging cage 90 degrees, and the hanging cage Lie flat and turn to upright, make opening door 111 be positioned at this hanging cage side, as Figure 6 As shown, the first crane 3 lifts the cage to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com