Ganoderma-lucidum-karst substitute cultivation medium inhibiting neurospora

A technology of substitute material cultivation and medium, applied in the field of Ganoderma lucidum substitute material cultivation medium, can solve the problems of discarding bacteria or bacteria bags, difficult to completely remove bacteria bags, destructive losses, etc., and achieve natural and pure ingredients, light and pleasant fragrance. People, the effect of preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

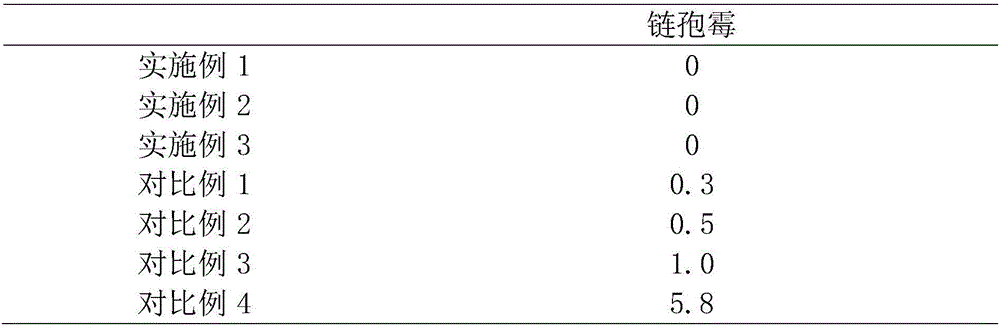

Examples

Embodiment 1

[0029] A kind of substituting material culture medium of Ganoderma lucidum that can inhibit Neurospora, made from the following raw materials: 40kg of maple sawdust, 40kg of cottonseed hulls, 0.5kg of gypsum, 2kg of sugar, 0.5kg of Artemisia argyi Atractylodes mixture, and the ratio of material to water is 1:1.3;

[0030] The described Artemisia argyi Atractylodis mixture is obtained by the following preparation method:

[0031] 1) Mix Artemisia argyi and Atractylodes atractylodes in a weight ratio of 1:2, put them into a distiller, heat and burn or pass in steam at the bottom of the distiller, when the hot steam is filled in the distiller, water vapor is introduced into condensation through the condenser tube In the container, the essential oil and pure dew are collected through the oil-water separator;

[0032] 2) High-speed dispersion and emulsification treatment: the essential oil and pure dew obtained in step 1) are put into a high-speed dispersion and emulsification mac...

Embodiment 2

[0034] A flat-covered Ganoderma lucidum substitute cultivation medium capable of inhibiting Neurospora, made of the following raw materials: 65kg of vertebral wood chips, 20kg of corn flour, 10kg of wheat bran, 1.5kg of gypsum, 0.5kg of sugar, 1.5kg of argyi leaves and atractylodes, The ratio of material to water is 1:1.5;

[0035] The described Artemisia argyi Atractylodis mixture is obtained by the following preparation method:

[0036]1) Mix Artemisia argyi and Atractylodes atractylodes in a weight ratio of 3:1, put them into a distiller, heat and burn or pass in steam at the bottom of the distiller, when the hot steam is filled in the distiller, water vapor is introduced into condensation through the condenser tube In the container, the essential oil and pure dew are collected through the oil-water separator;

[0037] 2) High-speed dispersion and emulsification treatment: the essential oil and pure dew obtained in step 1) are put into a high-speed dispersion and emulsific...

Embodiment 3

[0039] A kind of staghorn ganoderma substitute material cultivation medium that can inhibit Neurospora, made from the following raw materials: 50kg of maple wood chips, 35kg of wheat bran, 1.0kg of gypsum, 1.0kg of sugar, 1.0kg of Artemisia argyi Atractylodes mixture, and the ratio of material to water is 1:1.4;

[0040] The described Artemisia argyi Atractylodis mixture is obtained by the following preparation methods:

[0041] 1) Mix Artemisia argyi and Atractylodes atractylodes in a weight ratio of 2:1, put them into a distiller, heat and burn or pass in steam at the bottom of the distiller, when the hot steam is filled in the distiller, the water vapor passes through the condenser tube and is introduced into condensation In the container, the essential oil and pure dew are collected through the oil-water separator;

[0042] 2) High-speed dispersion and emulsification treatment: the essential oil and pure dew obtained in step 1) are put into a high-speed dispersion and emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com