Rubber antiskid and abrasion-resistant shoe sole and preparation method thereof

A slippery wear-resistant, shoe sole technology, applied in the field of rubber, can solve the problems of non-wearable and poor anti-skid effects, and achieve the effects of increased life, high anti-skid wear resistance, and guaranteed wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

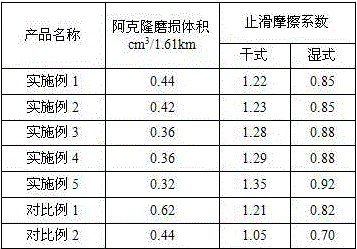

Examples

Embodiment 1

[0018] A rubber anti-slip and wear-resistant shoe sole, prepared from the following components by weight: 20 parts of butadiene rubber, 55 parts of natural rubber, 2 parts of sulfur, 4.5 parts of nano-zinc oxide, 1 part of stearic acid, and 0.5 parts of vulcanization accelerator DM 0.5 parts of nano-silicon nitride, 40 parts of carbon black, 3 parts of anti-aging agent DNP, 10 parts of diethyl phthalate, 7 parts of modified benzoxazine resin, 15 parts of dicyclopentadiene dioxide epoxy resin , 10 parts of B205 ceramic sand, 3 parts of high-performance hollow glass microspheres, and 7.5 parts of aramid fiber.

[0019] The preparation method of the above-mentioned rubber anti-slip wear-resistant shoe sole is: (1) pre-mixing: adding carbon black, butadiene rubber, natural rubber, nano-zinc oxide, stearic acid and diethyl phthalate into the internal mixer After masterbatching for 5 minutes, store at room temperature for 36 hours; (2) Mixing: Put the mixed rubber in step (1) into t...

Embodiment 2

[0021] A rubber anti-slip and wear-resistant shoe sole, which is prepared from the following components in parts by weight: 30 parts of butadiene rubber, 40 parts of natural rubber, 1 part of sulfur, 6.5 parts of nano-zinc oxide, 3 parts of stearic acid, and vulcanization accelerator DM 3 1.5 parts of nano-silicon nitride, 50 parts of carbon black, 1 part of anti-aging agent DNP, 6 parts of diethyl phthalate, 15 parts of modified benzoxazine resin, 5 parts of dicyclopentadiene dioxide epoxy resin , 5 parts of B205 ceramic sand, 8 parts of high-performance hollow glass microspheres, and 12.5 parts of aramid fiber.

[0022] The preparation method of the above-mentioned rubber anti-slip wear-resistant shoe sole is: (1) pre-mixing: adding carbon black, butadiene rubber, natural rubber, nano-zinc oxide, stearic acid and diethyl phthalate into the internal mixer After masterbatching for 12 minutes, store at room temperature for 24 hours; (2) Mixing: Put the mixed rubber in step (1) ...

Embodiment 3

[0024] A rubber anti-slip and wear-resistant shoe sole, which is prepared from the following components by weight: 22 parts of butadiene rubber, 50 parts of natural rubber, 1.8 parts of sulfur, 6 parts of nano-zinc oxide, 1.5 parts of stearic acid, and 2.5 parts of vulcanization accelerator DM 1.2 parts of nano-silicon nitride, 43 parts of carbon black, 1.8 parts of anti-aging agent DNP, 7 parts of diethyl phthalate, 13 parts of modified benzoxazine resin, dicyclopentadiene dioxide epoxy resin 8 parts, 10 parts of B205 ceramic sand, 7 parts of high-performance hollow glass microspheres, 11 parts of aramid fiber.

[0025] The preparation method of the above-mentioned rubber anti-slip wear-resistant shoe sole is: (1) pre-mixing: adding carbon black, butadiene rubber, natural rubber, nano-zinc oxide, stearic acid and diethyl phthalate into the internal mixer After masterbatching for 8 minutes, store it at room temperature for 30 hours; (2) Mixing: Put the mixed rubber in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com