Cooling process curve control structure of mobile hot air circulation annealing furnace with full fiber hood

A technology of hot air circulation and process curves, which is applied in the direction of heat treatment process control, furnace, furnace type, etc., can solve the problems of rolls not being able to perform the cooling rate correctly, quality defects, spray coating peeling, etc., to avoid heat treatment defects and improve heat treatment quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

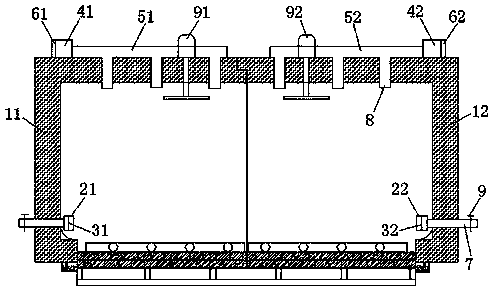

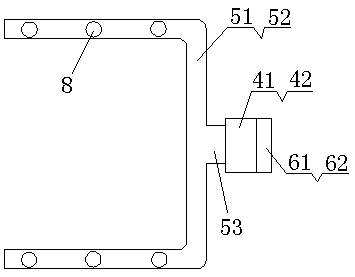

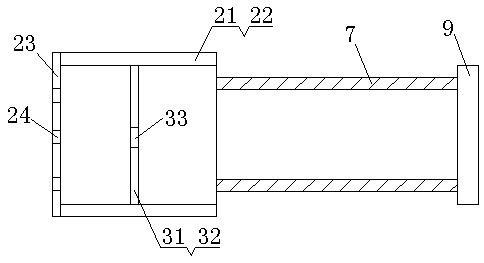

[0020] Example 1 as figure 1 , figure 2 and image 3 As shown, the full-fiber hood mobile hot air circulation annealing furnace cooling process curve control structure of the present invention includes two left and right full-fiber hoods 11, 12, two left and right square tubes 21, 22, two baffle plates 31, 32, two Two exhaust fans 41,42, two U-shaped pipes 51,52 with bottom openings, two outlet valves 61,62, some air inlet pipes 7, some air outlet pipes 8 and some air inlet valves 9, the left and right two full Both sides of the top surface of the fiber furnace cover 11, 12 are respectively spaced with a plurality of first through holes, the plurality of outlet pipes 8 are arranged in the first through holes, and the two U-shaped pipes 51, 52 are arranged in the first through holes. The top surfaces of the left and right full-fiber furnace covers 11, 12 are connected to the plurality of air outlet pipes 8, and the two air outlet valves 61, 62 and the two exhaust fans 41, 42...

Embodiment 2

[0025] Embodiment 2. On the basis of Embodiment 1, this structure also includes left and right centrifugal fans 91, 92, and the left and right centrifugal fans 91, 92 are respectively arranged on the top surfaces of the left and right full fiber furnace covers 11, 12 and the tuyere Located in the left and right two full-fiber furnace covers 11,12. The centrifugal fan is used to even the temperature in the furnace to avoid large temperature errors throughout the furnace, thereby ensuring the uniform heating of the stabilizing rollers in the furnace.

[0026] When the stabilizing rollers are performing heat treatment, open the left and right full-fiber hoods of the mobile hot air circulation annealing furnace, and the stabilizing rollers are placed horizontally on the hearth through the shelf, and then heat-treated, followed by heat-sealing process Among them, this structure is used to implement the cooling process curve control, which mainly includes:

[0027] 1. The cold air ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com