Acid rain corrosion-resistant austenitic stainless steel and manufacturing method thereof

An austenitic stainless steel and manufacturing method technology, applied in the field of austenitic stainless steel, can solve the problems of replacing 304 stainless steel, unusable supports, and low strength of stainless steel, so as to improve pitting resistance, meet service requirements, and be durable Effect of Dilute Sulfuric Acid on Corrosion Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

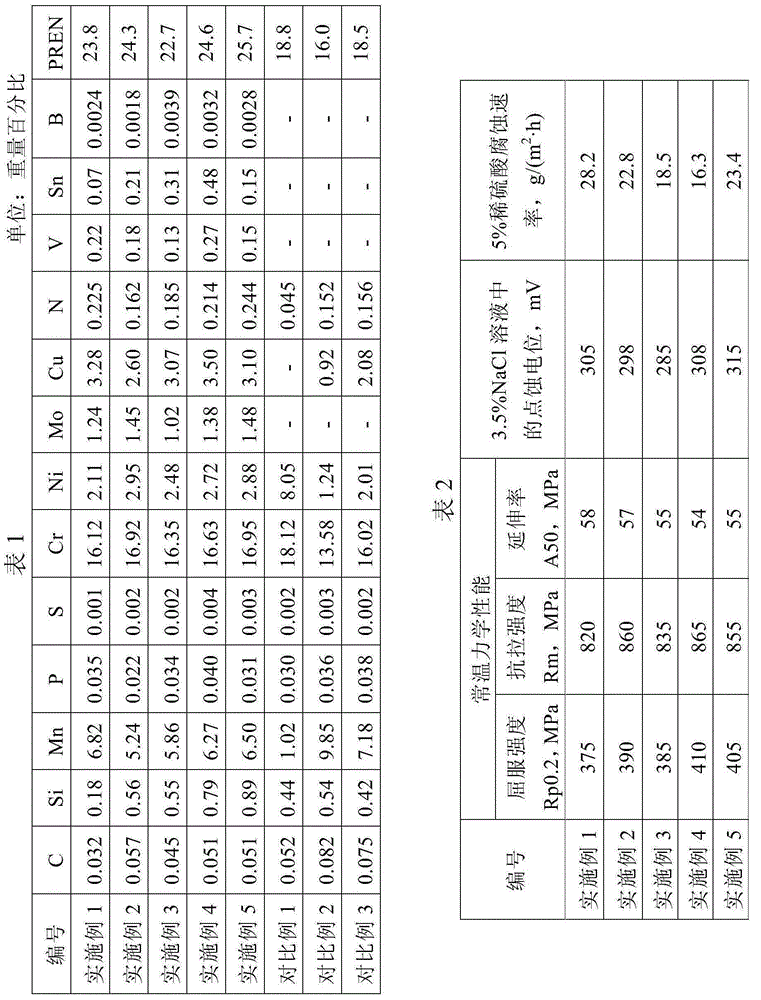

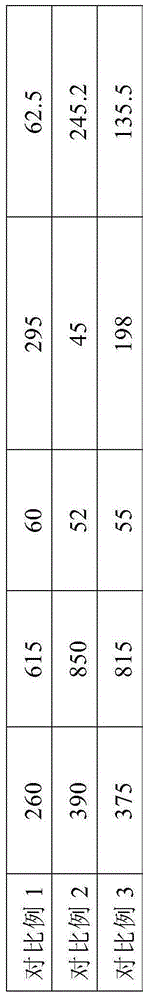

Examples

Embodiment 2

[0060] The steels with the chemical compositions shown in Example 2 and Comparative Example 1 were smelted in an electric furnace-AOD duplex, and continuously cast into 200mm thick slabs, wherein the Sn in Example 2 was added by means of tin-plated scrap steel plates; After the slab has been ground, it is heated to 1230°C in the heating furnace and then kept for 240 minutes. It is hot-rolled to a thickness of 3mm, and the final rolling temperature is 980-1020°C. Then it is laminar cooled to 630-680°C for coiling, and cooled to room temperature. The hot-rolled sheet is annealed on a continuous solution line at 1070-1100°C, with a belt speed of 30-50m / min, cooled to room temperature quickly, and then scale-breaking, shot blasting, electrolytic pickling, mixed acid pickling and other processes to remove scale ;The pickling plate is cold-rolled to a thickness of 1mm, the cold-rolled plate is solution annealed at 1060-1100°C, the annealing time is 1.5 minutes, and cooled to 60-75°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com