Aligning and leveling method for metal reactor core shell of nuclear power plant

A technology for nuclear power plants and metals, which is applied in the processing of building materials, construction, and building construction. It can solve problems such as the inability to meet the requirements for the installation and adjustment of metal core shells, and achieve good balance, increased applicability, and improved accuracy and quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be introduced below in conjunction with the accompanying drawings.

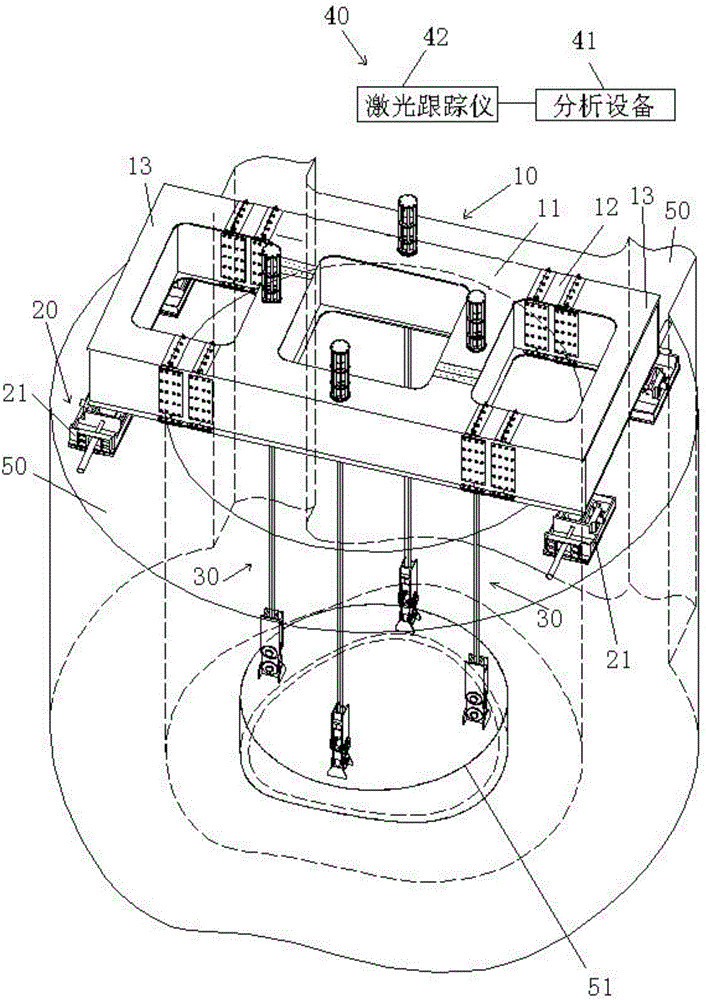

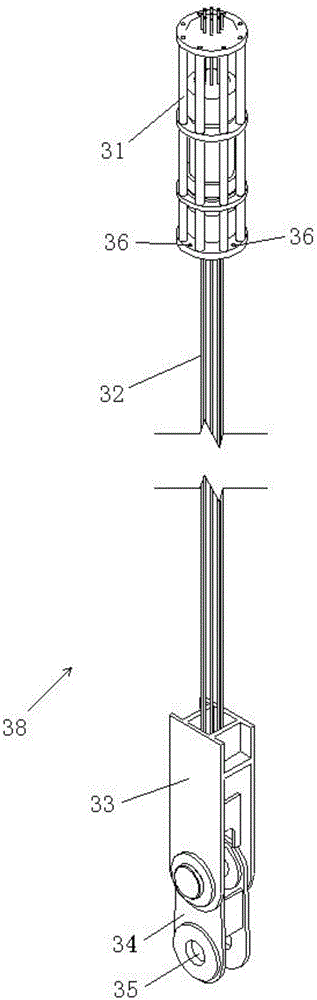

[0029] First introduce the used device of the method of the present invention, as figure 1 As shown, the apparatus used in the method of the present invention includes a structural beam 10 , a hydraulic adjustment system 20 , a cable system 30 and a measurement system 40 . The structural beam 10 , the hydraulic adjustment system 20 , the cable system 30 and the measurement system 40 are respectively introduced below.

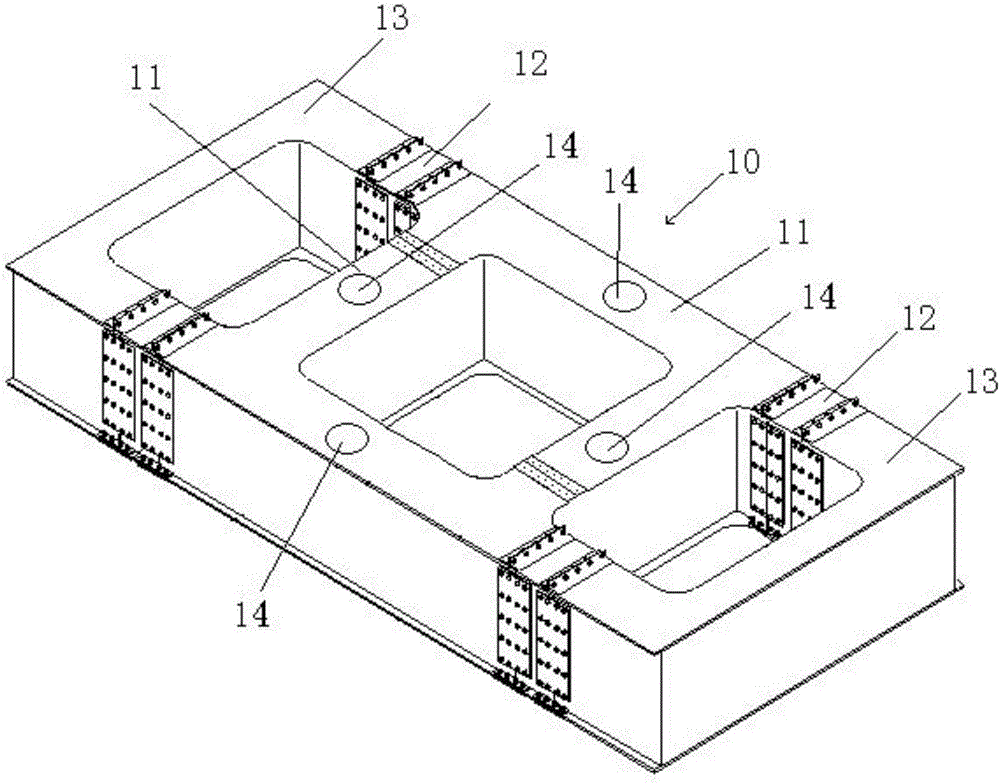

[0030] Such as Figure 1-2 As shown, the structural beam 10 is generally rectangular, and may be a steel structural beam. The lower surface of the structural beam 10 is provided with at least two fixing grooves (not shown in the figure), preferably, there are four fixing grooves distributed at the four corners of the structural beam 10 . Structural beam 10 can be detachably connected by several short beams. When in use, several short ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap