Blade type hand pump

A hand-operated pump and vane-type technology, which is applied in the field of volumetric pumps, can solve the problems of long water discharge cycle, low efficiency, and inapplicability, and achieve the effects of light operation, saving production costs, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

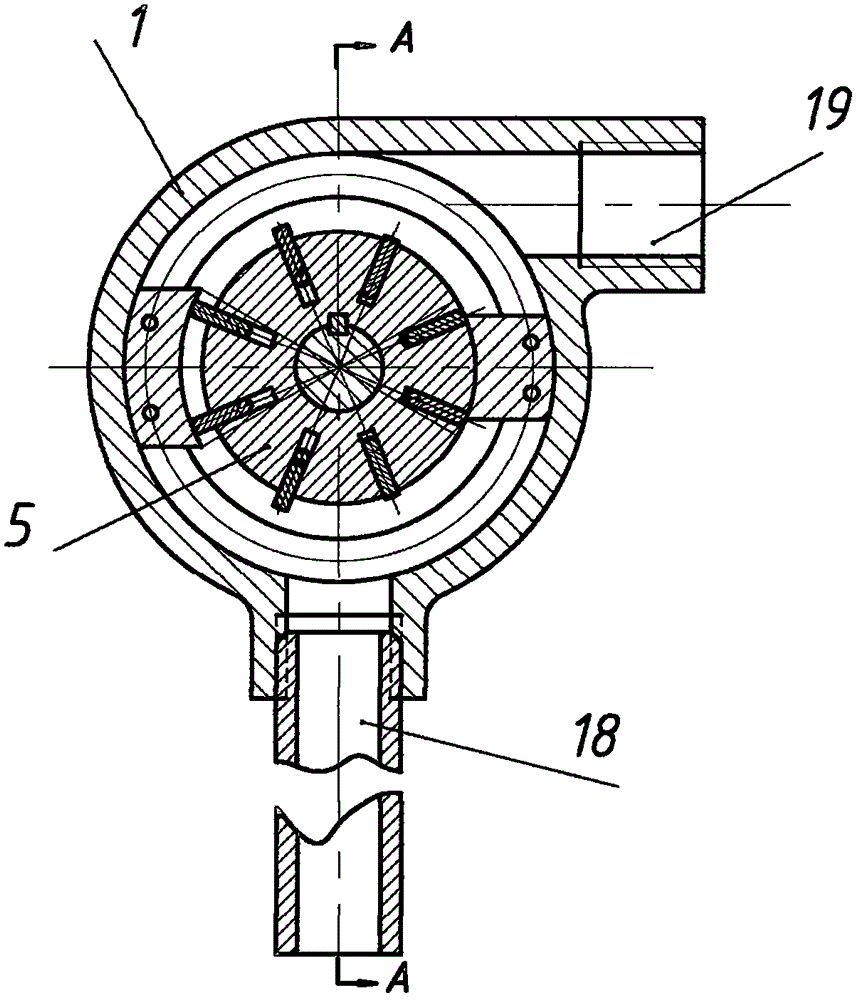

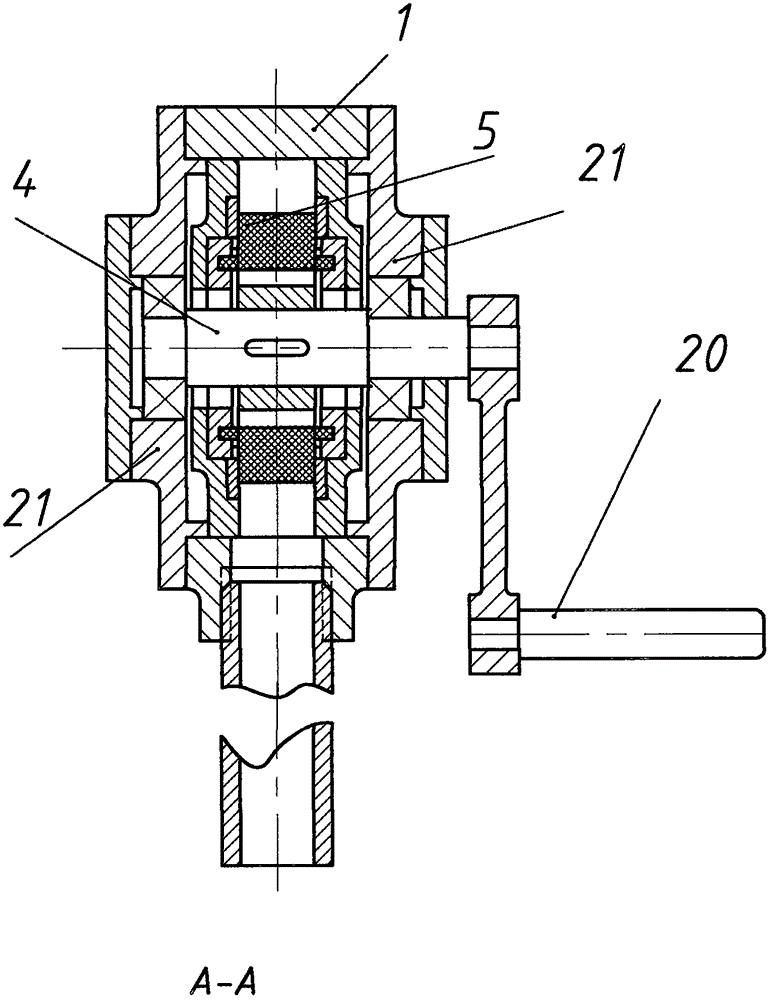

[0027] figure 1 is a structural diagram of an embodiment of the present invention, figure 2 Yes figure 1 A-A sectional view.

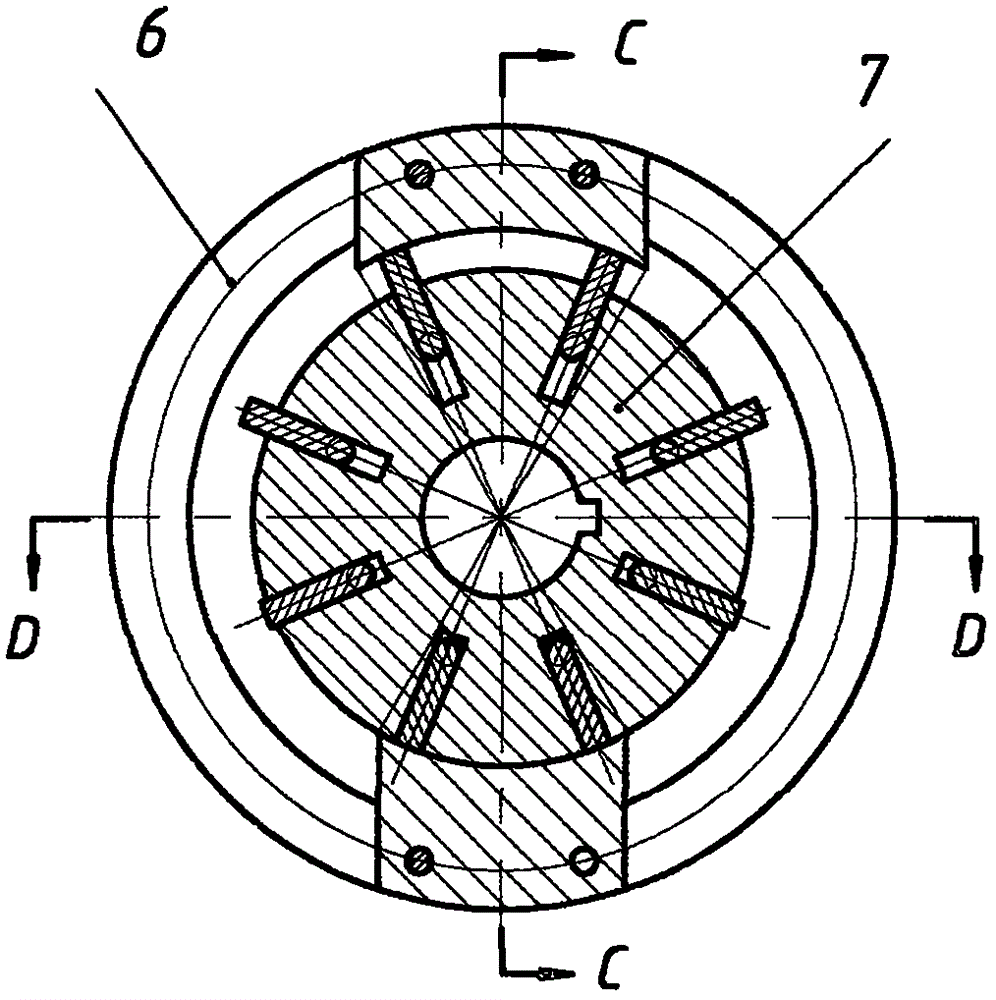

[0028] The figure shows: the side cover 21 is installed on both sides of the pump body 1 with the suction port and the discharge port, and the vane pump modular unit 5 is installed in the inner cavity of the pump body 1. The modular unit 5 is composed of the pump chamber assembly 6 and the The rotor assembly 7 is composed of two parts, and the pump chamber assembly 6 is composed of four parts including the upper partition tongue 8, the lower partition tongue 9, the front partition plate 10 and the rear partition plate 11. They are fixed together, and the upper partition tongue 8 and the lower partition tongue 9 separate the pump chamber into a low-pressure area and a high-pressure area. The front baffle 10 and the rear baffle 11 are equipped with a circular arc triangular equal-width cam groove plate coaxial with the rotor 2 toward the inner side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com