Heat superconductivity heating-panel-type electric heater

A heat dissipation plate and thermal superconducting technology, which is applied in the field of thermal superconducting heat dissipation plate electric heaters, can solve the problems of easy leakage and deflagration, low safety performance, slow start-up speed, etc., and achieve high heating efficiency, fast heating rate, The effect of safety on the human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

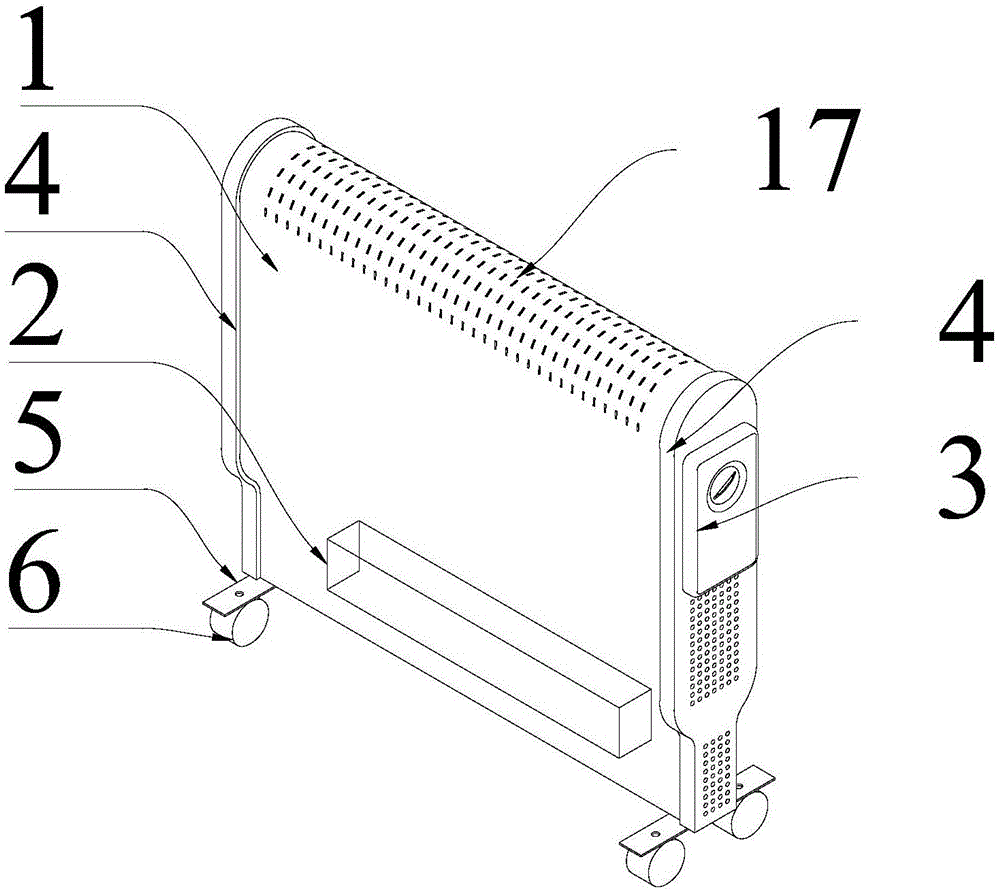

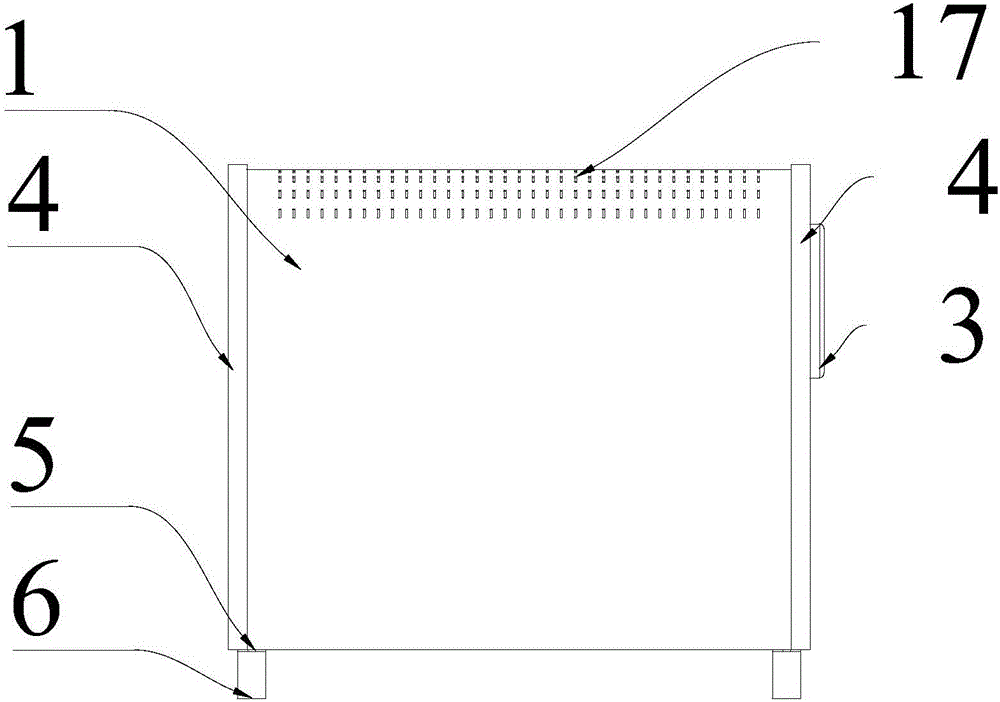

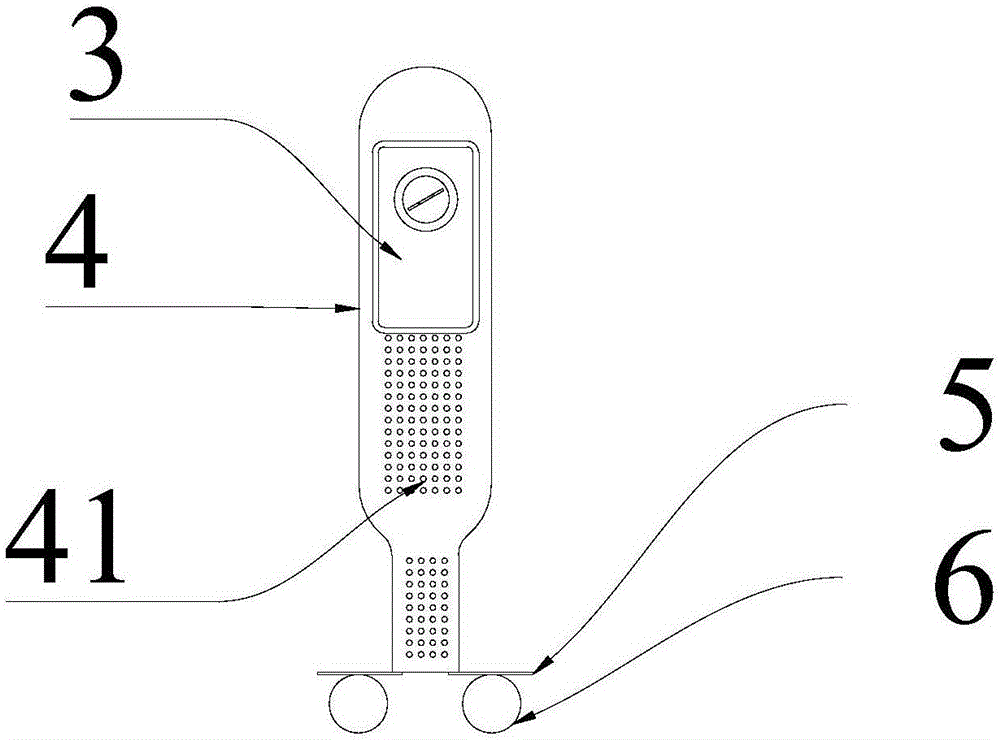

[0062] See Figure 1 to Figure 6 , The present invention provides a thermal superconducting radiating plate type electric heater, the thermal superconducting radiating plate type electric heater includes: a thermal superconducting radiating plate 1, the thermal superconducting radiating plate 1 is a composite plate structure, formed inside A thermal superconductor circuit 13 of a specific shape, the thermal superconductor circuit 13 is a closed pipeline, and the thermal superconductor circuit 13 is filled with a heat transfer working medium 16; an electric heating heat source 2, the electric heating heat source 2 is fixed to The surface of the thermal superconducting heat sink 1; an electric heater control box 3, the electric heater control box 3 is connected to the electric heating heat source 2, suitable for controlling the electric heating heat source 2.

[0063] As an example, such as Figure 1 to Figure 4 As shown, the shape of the longitudinal section of the thermal supercon...

Embodiment 2

[0077] See Figure 7 to Figure 9 , This embodiment also provides a thermal superconducting heat dissipation plate type electric heater, the thermal superconducting heat dissipation plate type electric heater includes: a thermal superconducting heat dissipation plate 1, the thermal superconducting heat dissipation plate 1 is a composite plate structure, and the interior A thermal superconductor circuit 13 of a specific shape is formed, the thermal superconductor circuit 13 is a closed pipeline, and the thermal superconductor circuit 13 is filled with a heat transfer working medium 16; an electric heating heat source 2, the electric heating heat source 2 Fixed on the surface of the thermal superconducting heat sink 1; an electric heater control box 3, the electric heater control box 3 is connected with the electric heating heat source 2 for controlling the electric heating heat source 2.

[0078] As an example, the thermal superconducting heat sink 1 includes a main body portion 18...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap