Long-distance distributed optical fiber vibration monitoring device and realization method thereof

A distributed optical fiber and vibration monitoring technology, which is applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of high difficulty of zero point positioning algorithm, low hardware cost, poor positioning accuracy, etc., to improve optical signal transmission The effect of distance and signal analysis and recognition ability, application cost reduction, and economic benefit improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

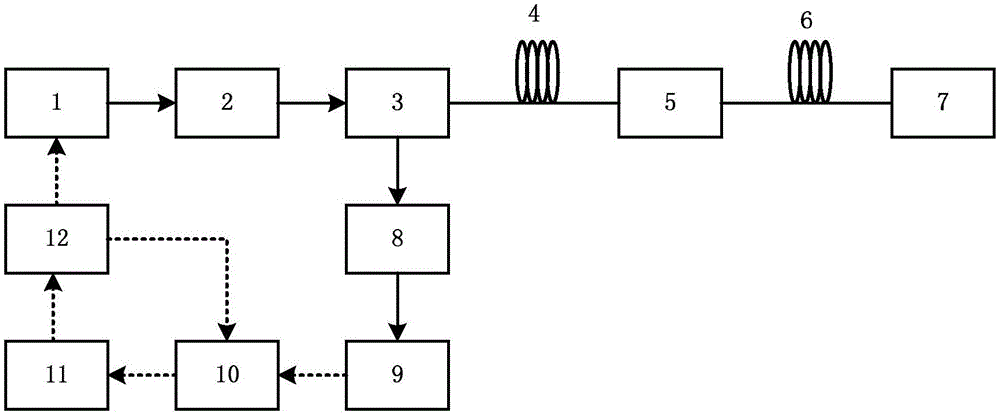

[0027] First, the pulse source (1) emits laser pulses, and the signal is amplified by the optical fiber amplifier (2) as a light source signal;

[0028] Second, the light source signal is delivered to the actual laying detection fiber 1 (4) through the 2 ports of the circulator (3), and each pulsed light arrival position in the fiber will generate a Rayleigh scattering signal, and the surrounding environmental vibration will is loaded into the Rayleigh scattering signal, causing its phase to change;

[0029] Third, after the light source reaches 25km in the detection fiber 1 (4), its energy decreases due to its attenuation, and the energy of its scattered signal is greatly reduced. After passing through the relay amplifier module (5), the light source and the amplified laser enter the detection fiber 2 ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com