Rotating shaft system rotational inertia in-situ measurement device

A moment of inertia, in-situ measurement technology, applied in the direction of measuring device, static/dynamic balance test, machine/structural component test, etc., to achieve the effect of high measurement accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

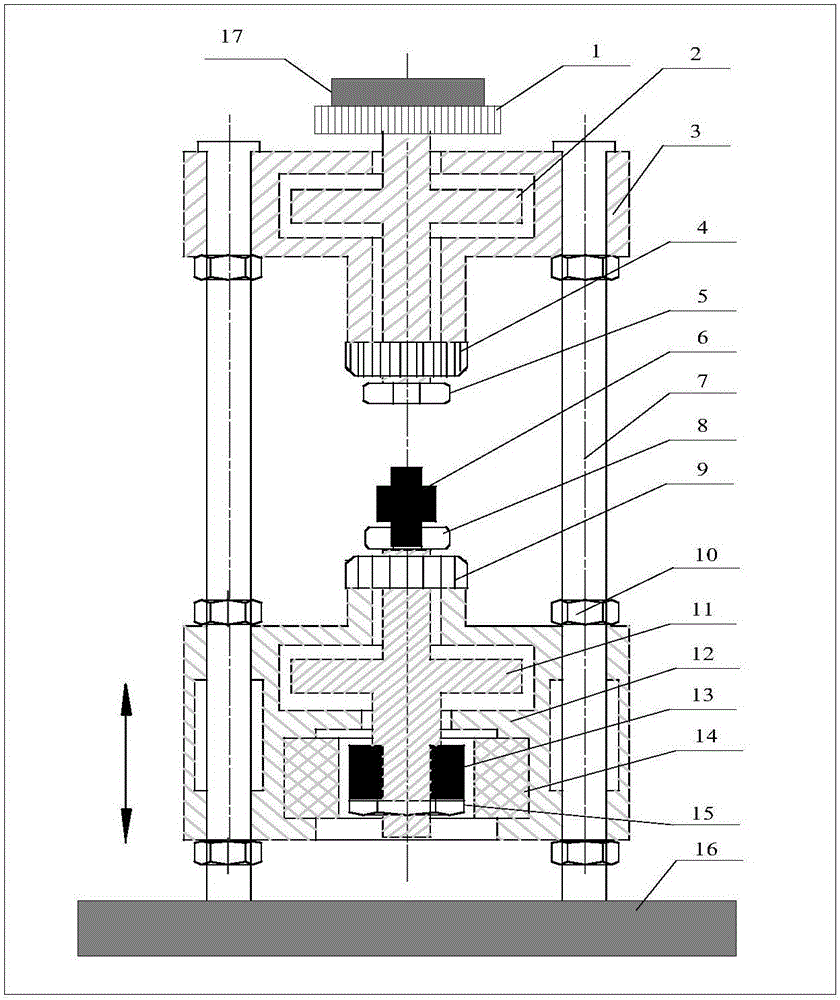

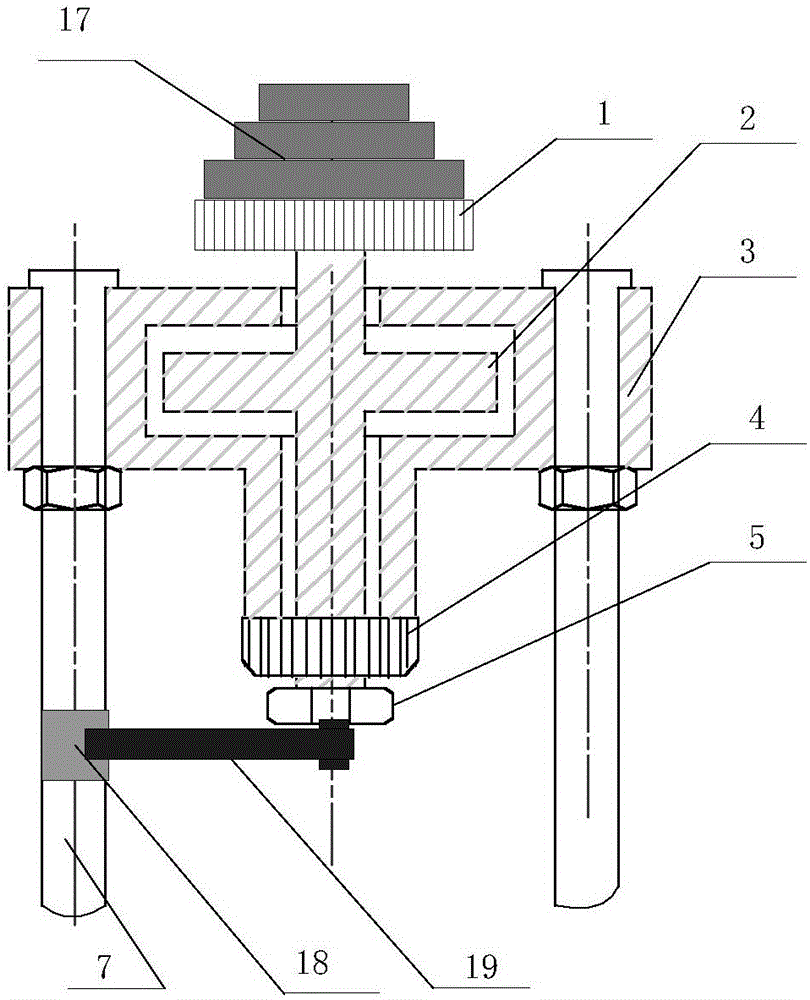

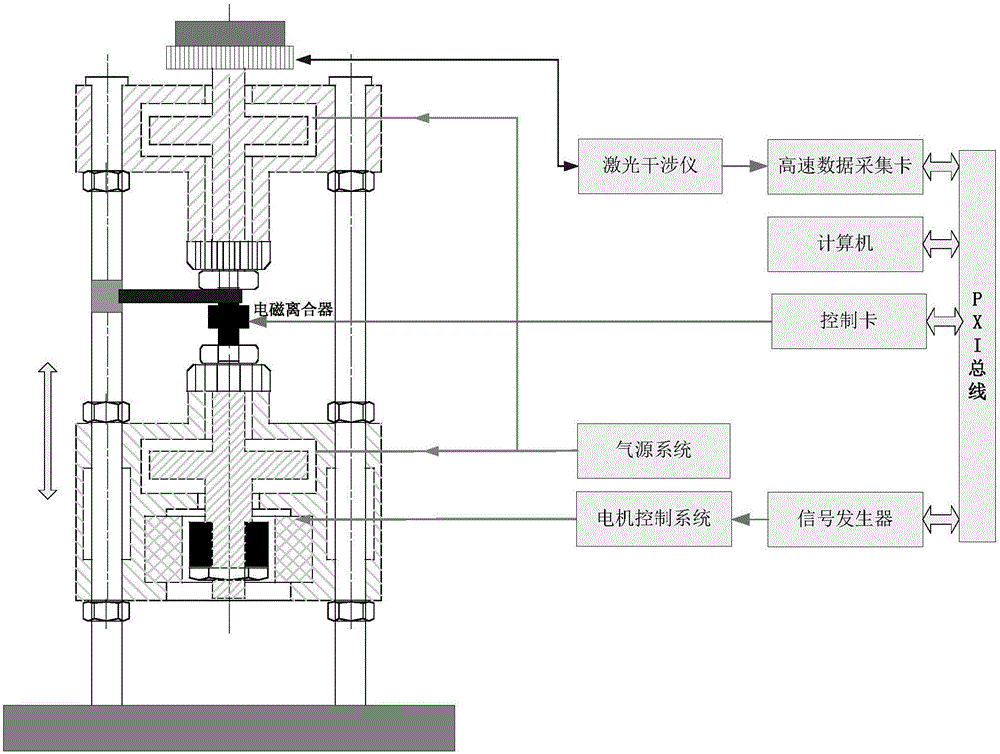

[0028] In-situ measuring device for the moment of inertia of the rotating shaft system, such as figure 2 As shown, it consists of an upper structure and a torsion system; the upper structure table top grating 1, the upper air bearing shaft 2, the upper bearing seat 3, the cylindrical grating 4, the upper interface 5 and the inertia standard block 17; the torsion system includes a fastening mechanism 18 and The torsion spring 19; the inertia standard block 17 is placed on the table top grating 1; the upper bearing seat 3 is an inverted convex structure with a through hole in the middle and a cavity inside; the cavity wall of the upper bearing seat 3 is provided with air passages and Air holes; the upper air bearing shaft 2 is a cross structure, and the upper air bearing shaft 2 is placed in the inner cavity of the upper bearing seat 3. When the cavity is filled with gas, the upper air bearing shaft 2 does not contact the upper bearing seat 3; the upper air bearing shaft 2 The ...

Embodiment 2

[0042] The structure of the in-situ measuring device for the moment of inertia of the rotating shaft system is the same as in Embodiment 1; the lower structure consists of the sensor to be calibrated 6, the lower interface 8, the feedback grating 9, the lower air bearing shaft 11, the lower bearing seat 12, the motor rotor 13, and the motor stator 14, composed of lock nut 15; the lower bearing seat 12 is a convex structure, with a through hole in the middle, and two upper and lower inner cavities inside; the lower air bearing shaft 11 is a cross structure, and the upper inner cavity of the lower bearing seat 12 is filled with The lower air bearing shaft 11 is not in contact with the lower bearing seat 12 when there is gas; the lower air bearing shaft 11 is placed in the upper inner cavity, the shaft passes through the through hole in the middle of the lower bearing seat 12, and the top end passes through the feedback grating 9 and is fixedly connected to the lower interface 8 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com