Wrapping and molding manufacturing method for middle connector of cross-linked polyethylene insulated power cable

A cross-linked polyethylene and power cable technology, applied in circuits, connections, electrical components, etc., can solve the problems of local electric field distortion, insulation breakdown, the inability of insulating media to solve the air gap of the matching interface, etc., to achieve convenient operation and electrical performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

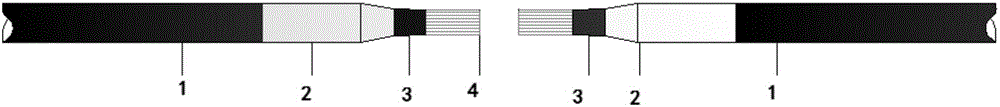

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] The on-site production method of wrapping molding for 500V to 48kV XLPE cable intermediate joint includes the following steps:

[0034] Step a. According to the requirements of the manufacturing process, remove the outer sheath and metal sheath of the cables at both ends, and retain the water-blocking buffer tape; clean the surface of the metal sheath of the cable, and use a file to remove the corner burrs at the end of the metal sheath.

[0035] Step b. Cable pretreatment:

[0036] Surface treatment of the outer semiconducting layer: the fracture of the outer semiconducting layer should be perpendicular to the axis of the cable and flat, and the groove should be cut with a knife within 30mm of the fracture of the outer semiconducting layer (the direction of the knife edge faces the outer semiconducting layer to avoid cutting the insulating layer) , Wrap 3 laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com