Glass breaker

A glass-breaking and mounting hole technology, applied in life-saving equipment, building rescue, etc., can solve the problems of large safety control, high glass-breaking starting voltage and current, hidden safety hazards, etc., achieving low starting voltage and starting current, guaranteeing Long-term use reliability and the effect of solving security control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

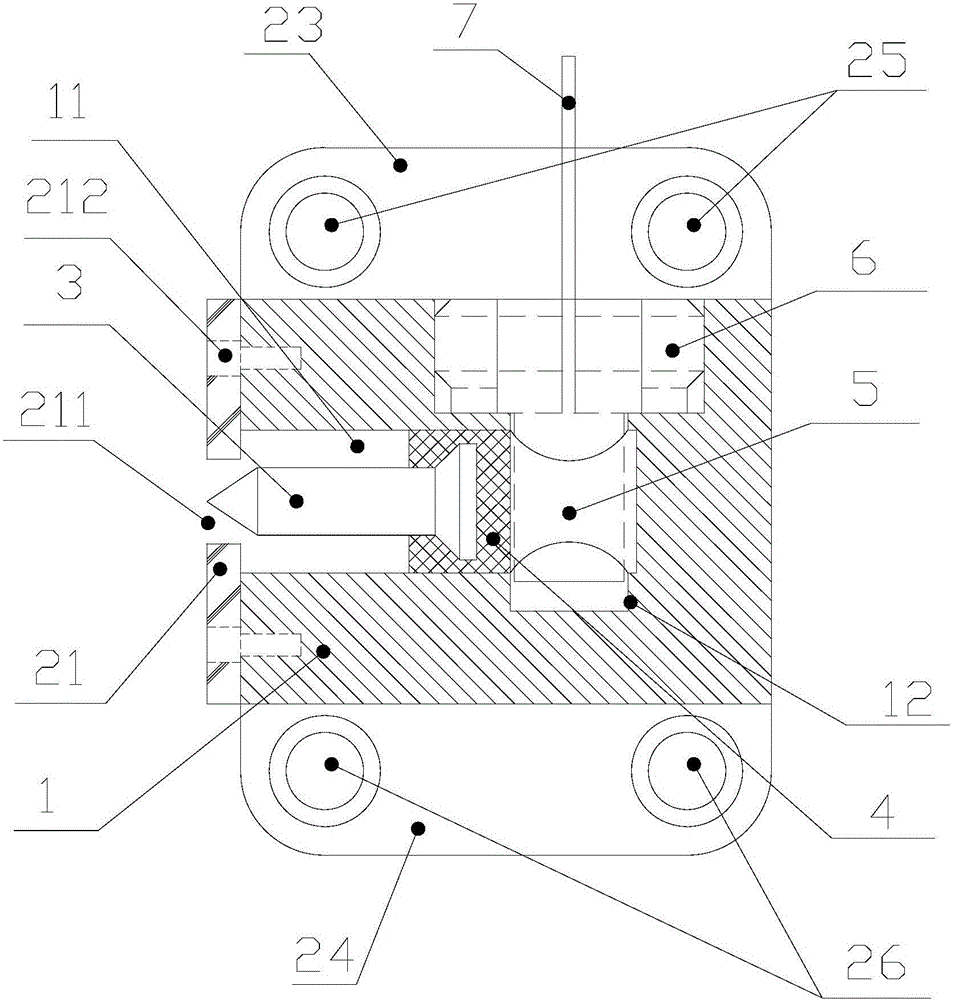

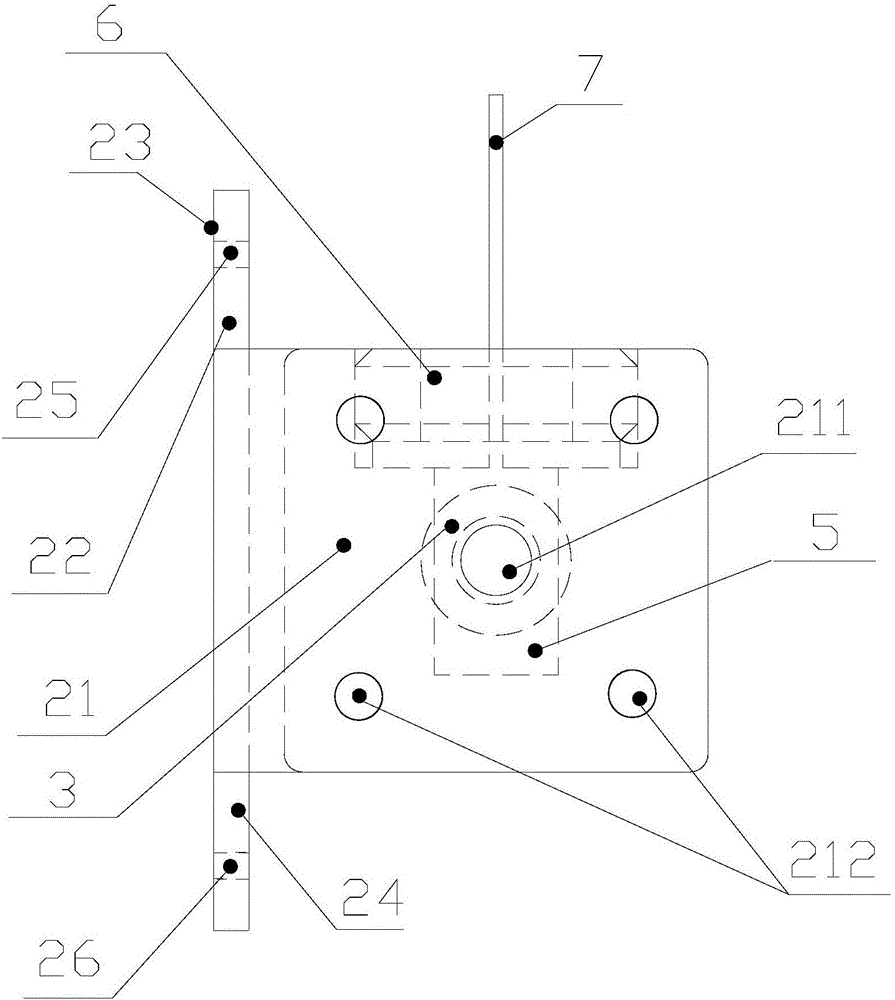

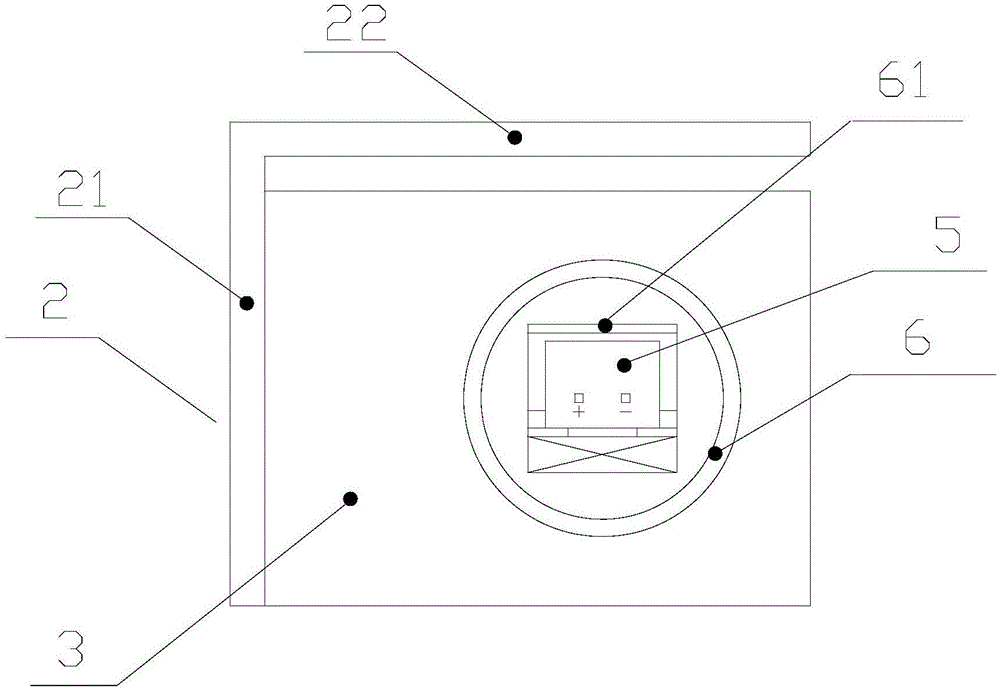

[0034] In the present invention, the structure of starting glass breaking is designed as an electric heating gas generating element composed of electric heating resistance wire and chemical gas generating medicine, which ensures the long-term reliability of the product, so that there is no need to use gunpowder for starting glass breaking, electric heating The size of the gas-generating element is small, and the start-up voltage and current for breaking the glass are low, which solves the problem of safety control in the production process.

[0035] In addition, the impact part is an alloy nail, whose hardness can ensure the effective breaking of various glasses. The top structure ensures that the broken structure of the glass after breaking the glass is cracked, thus avoiding accidental damage caused by glass splashing. The present invention will be described in detail below in conjunction with specific implementation methods and accompanying drawings.

[0036] like Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com