Dressing apparatus and dressing method of polishing pad of double-side polishing apparatus

A double-sided grinding and dressing device technology, applied in abrasive surface adjustment devices, parts of grinding machine tools, grinding/polishing equipment, etc., can solve problems such as poor work efficiency, difficulty in performing precise grinding, and troublesome control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

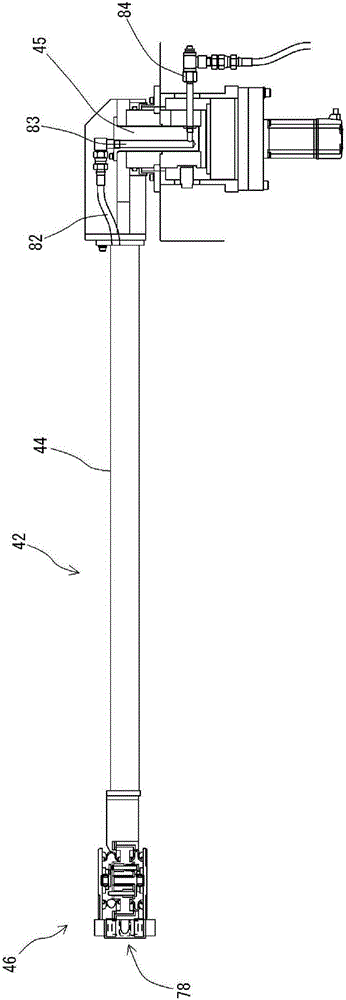

[0048] Hereinafter, suitable embodiments of the present invention will be described in detail based on the drawings.

[0049] First, an example of a double-side grinding device will be described.

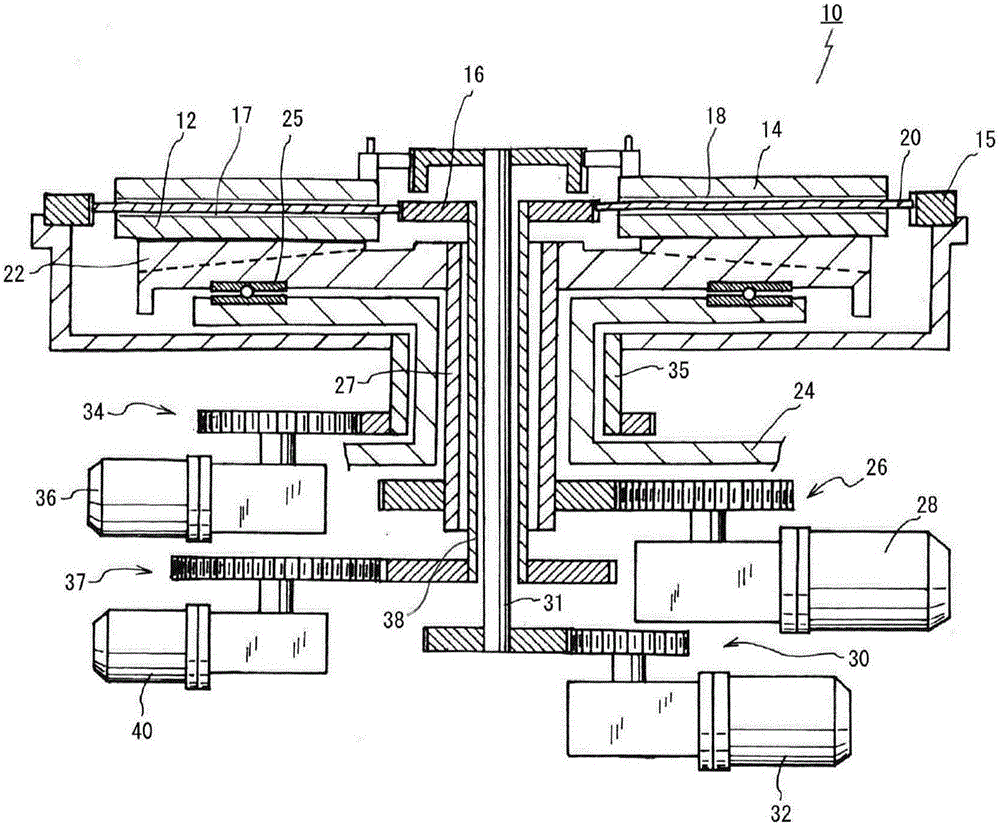

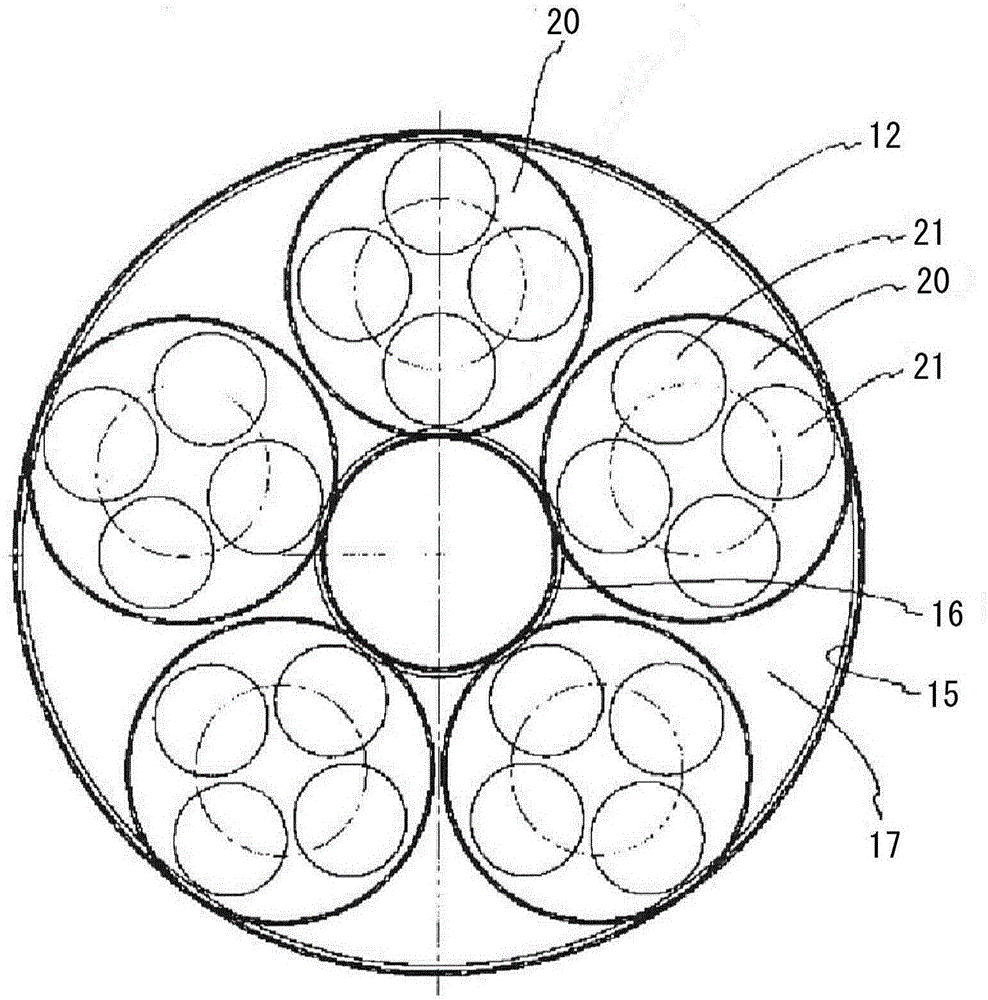

[0050] figure 1 is a cross-sectional view of a double-sided grinding apparatus 10 that grinds a workpiece such as a silicon wafer. figure 2 is a plan view showing the relationship between the lower grinding plate and its carrier.

[0051] exist figure 1 In the shown arrangement, a carrier 20 driven by an internal gear 15 and a sun gear 16 is disposed between a lower grinding plate 12 and an upper grinding plate 14 rotating in opposite directions to each other.

[0052] Grinding pads 17 and 18 are attached to the upper surface of the lower grinding plate 12 and the lower surface of the upper grinding plate 14, respectively.

[0053] A through hole 21 supporting a workpiece to be ground is drilled in the carrier 20 , and both surfaces of the workpiece supported by the through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com