Preparation method and application of Bi2Ti4O11:Yb, Er up-conversion luminescence anti-counterfeiting film

A thin-film, uniform technology, applied in rayon manufacturing, fiber chemical characteristics, instruments, etc., can solve problems such as complex equipment, achieve high safety, avoid the use of toxic inks, and have good concealment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

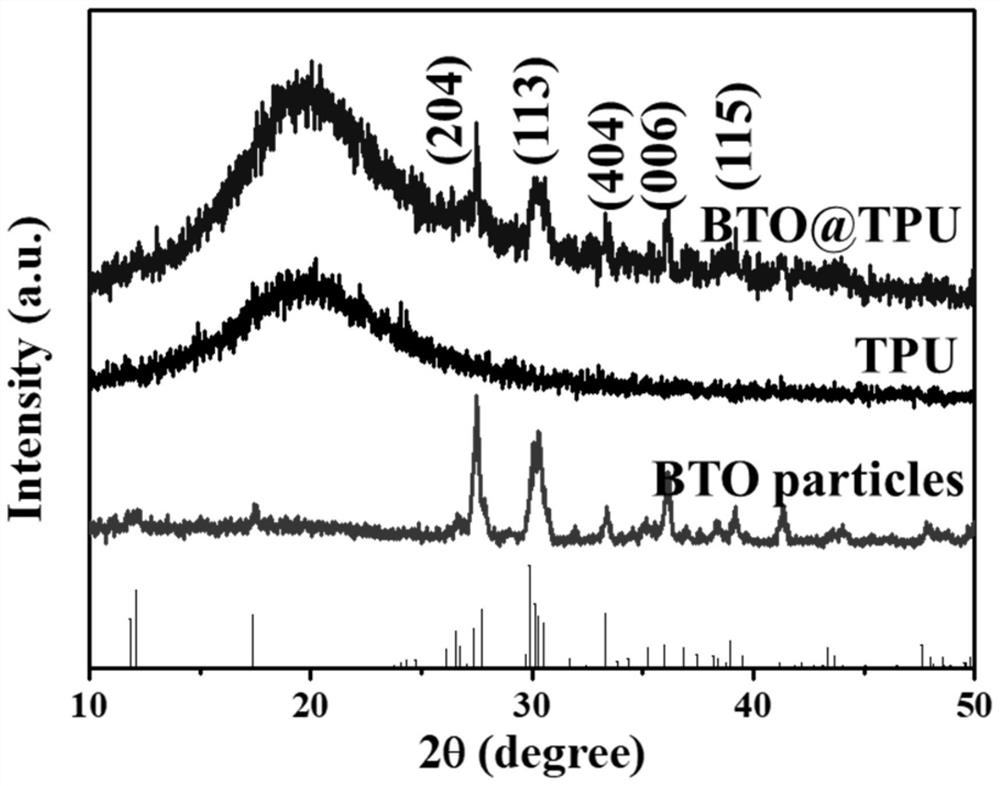

[0050] A kind of Bi of the present invention 2 Ti 4 o 11 : Yb, the preparation method of Er up-conversion luminescence anti-counterfeiting film, comprises the following steps:

[0051] S1. Mix DMF with HAC and TBOT at a mass ratio of (3-5): 1:1 to obtain solution A;

[0052] S2, adding bismuth nitrate with a mass ratio of (0.17 to 0.23): 1 to solution A into solution A, and obtaining solution B after fully stirring;

[0053] S3, adding ytterbium nitrate and erbium nitrate in solution B successively, wherein the mass fraction of erbium nitrate is 2%, and the mass ratio of ytterbium nitrate and erbium nitrate is (5~20):1, obtains solution C after fully dissolving;

[0054] S4, the solution C is evaporated to dryness, the temperature of the treatment is 250° C., and the treatment time is 2-3 hours, and a gray-black powder is obtained;

[0055] S5, annealing the powder in a muffle furnace, the annealing temperature is 800-1000°C, and the annealing time is 6-8h;

[0056] S6. M...

Embodiment 1

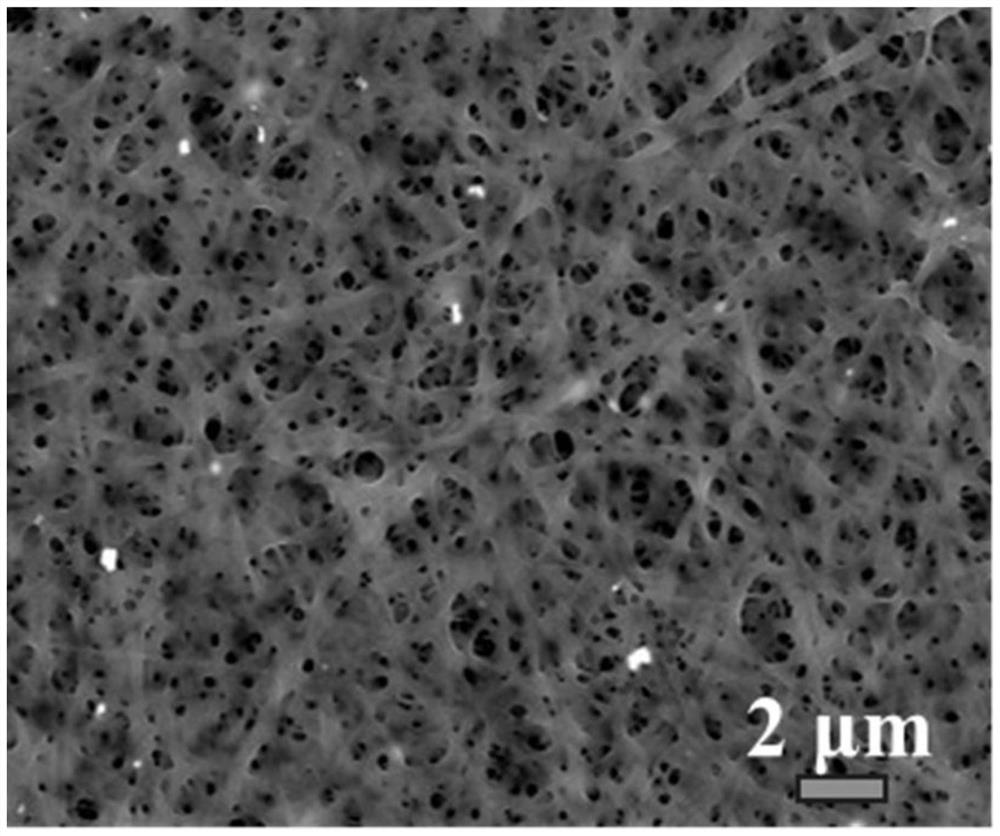

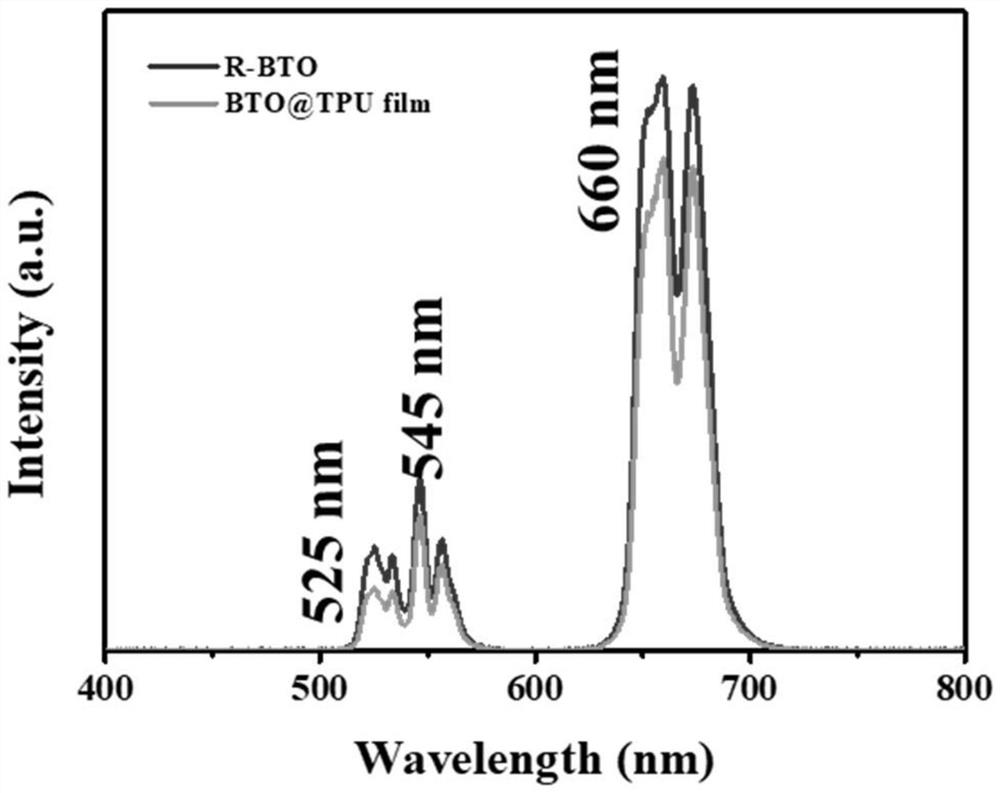

[0064] Mix DMF, HAC and TBOT uniformly according to the mass ratio of 3:1:1 to form a transparent solution A; then add bismuth nitrate with a mass ratio of 0.17:1 to solution A under magnetic stirring to obtain solution B; Add ytterbium nitrate and erbium nitrate, wherein the mass fraction of erbium nitrate is 2%, and the mass ratio of ytterbium nitrate to erbium nitrate is 5:1. After dissolving, solution C can be obtained; solution C is evaporated to dryness at 250°C for 2 hours , and then the obtained powder was moved into a muffle furnace and treated at 800 °C for 6 h to obtain Bi with high crystallinity and up-conversion luminescence properties. 2 Ti 4 o 11 : Yb 3+ , Er 3+Powder. Mix TPU, THF and DMF uniformly at a mass ratio of 0.3:1:1 to obtain a transparent solution D with a certain viscosity, and then add Bi with a mass fraction of 8% 2 Ti 4 o 11 : Yb 3+ , Er 3+ The powder is dispersed into the solution D to obtain the electrospinning precursor. Transfer the ...

Embodiment 2

[0067] Mix DMF, HAC and TBOT uniformly according to the mass ratio of 3.5:1:1 to form a transparent solution A; then add bismuth nitrate with a mass ratio of 0.19:1 to solution A under magnetic stirring to obtain solution B; Add ytterbium nitrate and erbium nitrate, wherein the mass fraction of erbium nitrate is 2%, and the mass ratio of ytterbium nitrate to erbium nitrate is 10:1. After dissolving, solution C can be obtained; solution C is evaporated to dryness at 250°C for 3 hours , and then the obtained powder was moved into a muffle furnace and treated at 850 °C for 7 h to obtain Bi with high crystallinity and up-conversion luminescence properties. 2 Ti 4 o 11 : Yb 3+ , Er 3+ Powder. Mix TPU, THF and DMF uniformly at a mass ratio of 0.3:1:1 to obtain a transparent solution D with a certain viscosity, and then add 9% Bi 2 Ti 4 o 11 : Yb 3+ , Er 3+ The powder is dispersed into the solution D to obtain the electrospinning precursor. Transfer the electrospinning prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com