A rare earth-doped up-conversion nanocrystalline luminescent material and its preparation method

A technology of rare earth doping and luminescent materials, applied in luminescent materials, nano optics, nanotechnology, etc., can solve the problems of high temperature and low luminous efficiency, and achieve the effect of low crystallization temperature and good up-conversion luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

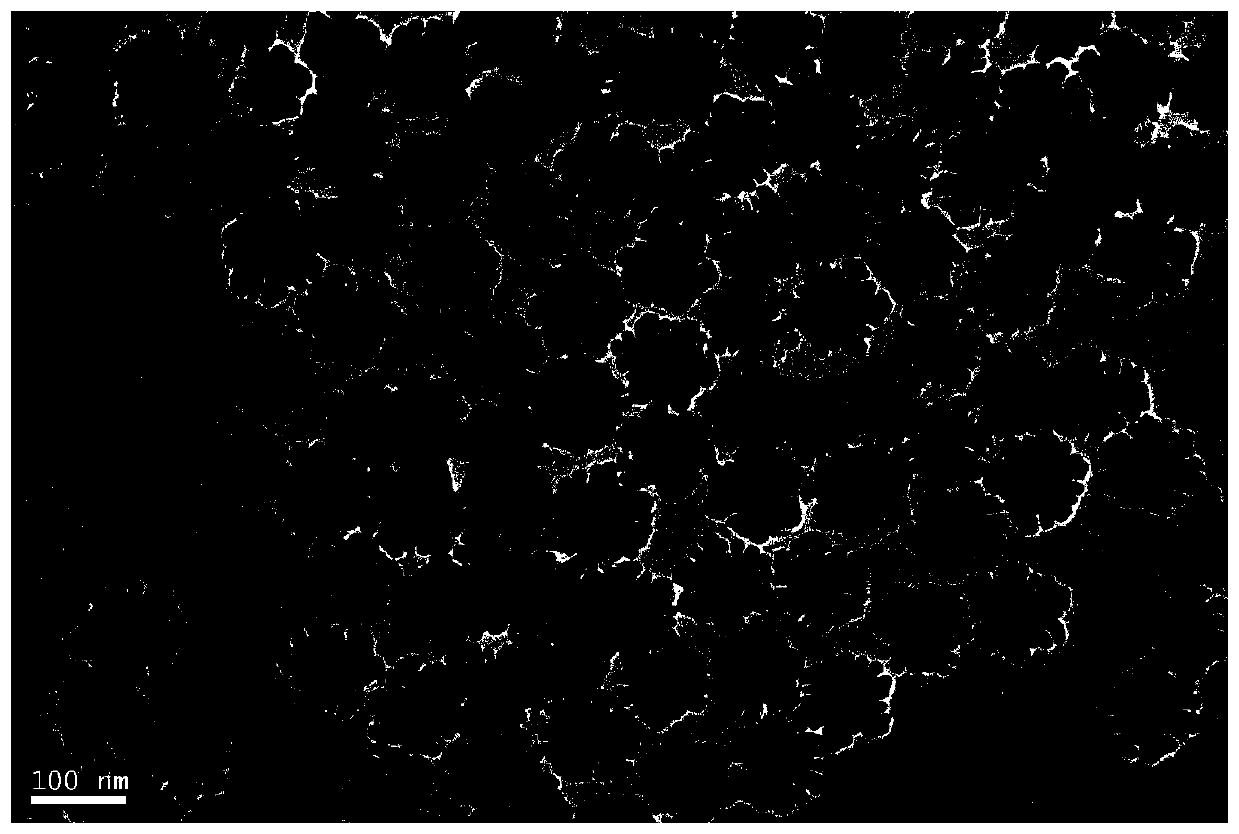

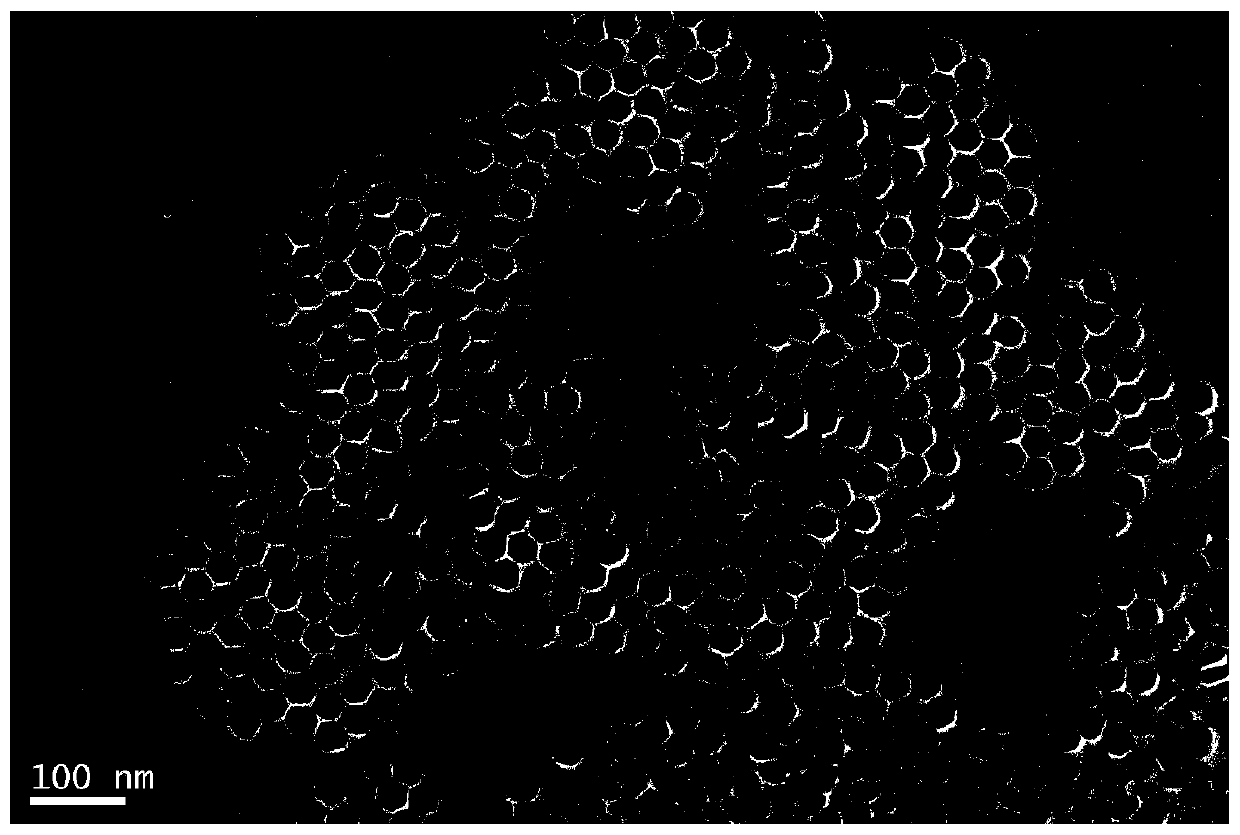

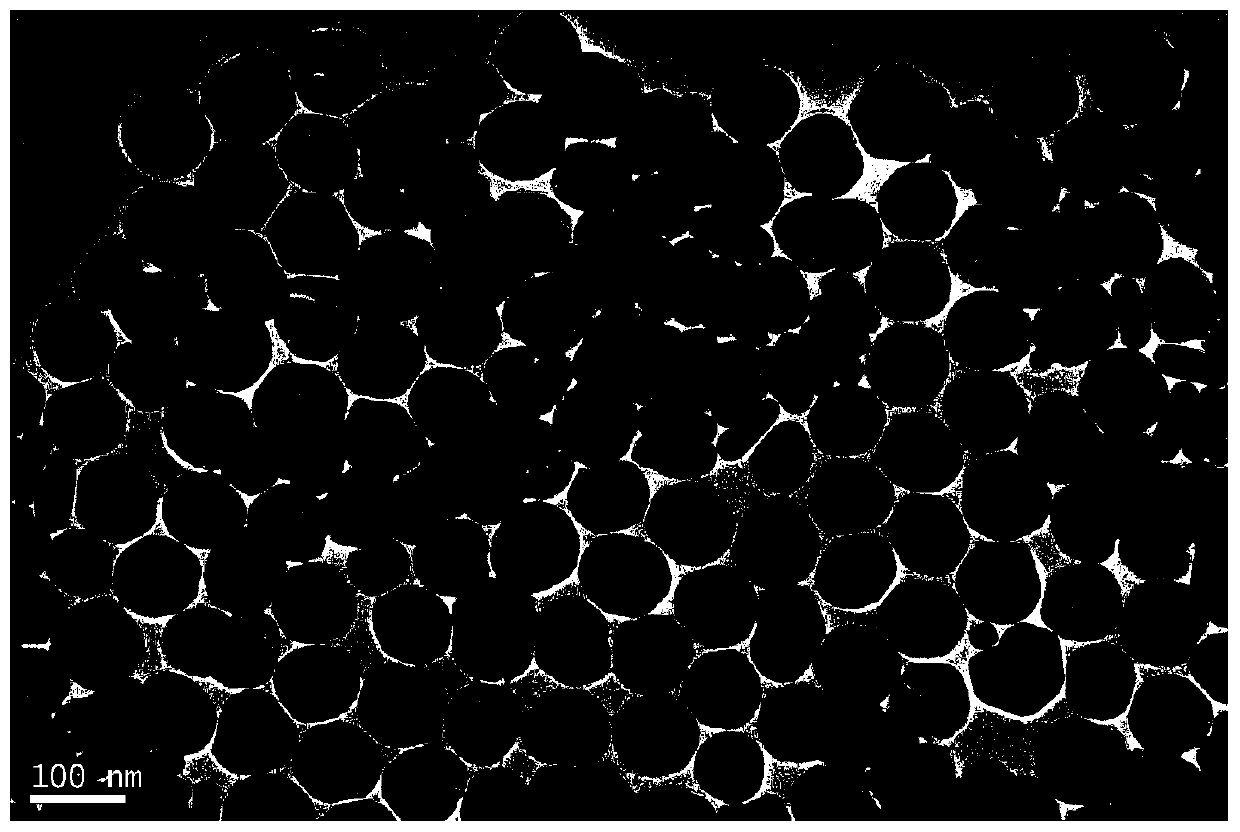

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing rare earth-doped up-conversion nanocrystalline luminescent material, including:

[0041] (1) In a two-necked flask, add yttrium acetate (1.6mL, 0.2M), ytterbium acetate (0.4mL, 0.2M), thulium acetate (0.04mL, 0.02M), oleic acid (90%) and 1- Octadecene (90%), heated to 150°C in a heating mantle and kept for 1 hour to remove the water in the solution to obtain the first reaction liquid containing the rare earth-oleic acid complex precursor; among them, oleic acid and 1 -The volume ratio of octadecene is 3:7.

[0042] (2) Cool the first reaction solution to room temperature, evacuate and vent argon, and add NaOH (1mL, 1M) and NH through a single-channel syringe pump at a drip rate of 0.5mL / min under argon atmosphere 4 F (3.8mL, 0.4M), raise the temperature to 45℃, keep stirring under argon atmosphere for 1h; then, raise the temperature to 110℃ to remove methanol in the solution; then raise the temperature under argon atmosphere A...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is:

[0046] NH 4 The molar ratio of F to NaOH is 1.6:1;

[0047] The sample obtained is labeled Sample 2.

[0048] The other parts are basically the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0050] The difference between this embodiment and Embodiment 1 is:

[0051] The crystallization temperature of step (2) is 280°C;

[0052] The sample obtained is labeled Sample 3.

[0053] The other parts are basically the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com