A rare earth up-conversion luminescent nanomaterial with controllable synthesis of core-shell structure and its preparation method and application

A rare earth up-conversion and nano-material technology, which is applied in the field of nano-materials to achieve the effects of good up-conversion luminescence performance, broad application prospects and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1, NaGdF 4 Preparation of small nanoparticles

[0061] (1) Add GdCl to a 100mL three-necked flask 3 0.830mmol, then add 8mL oleic acid, 8mL oleylamine and 16mL octadecene, pump the system to vacuum, stir at 70°C for 0.5h, inflate twice with argon during this period, and completely exhaust the air in the system. It was then heated to 120 °C to obtain a clear solution and kept for 45 min. Cool to room temperature.

[0062] (2) 4mmol NH 4 F and 2.5mmol NaOH were added to the above mixed solution. The system was evacuated again with an oil pump, and stirred at 70°C for 2.5 hours to obtain a clear solution. During this period, the system was inflated twice with argon to completely discharge the air in the system.

[0063] (3) Then close the air valve, slowly heat to 300°C at a rate of 10°C / min, and keep for 1.5h. Then continue to heat up to 320°C, and keep it for 20min until it cools down to room temperature naturally.

[0064] (4) Pour into a centrifuge tube...

Embodiment 2

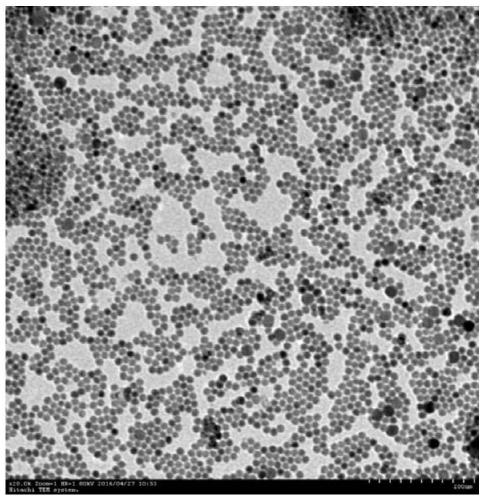

[0066] Example 2, NaYF 4 Preparation of :Yb:Er Core Nanoparticles

[0067] (1) Add YCl to a 100mL three-necked flask 3 0.83mmol, YbCl 3 0.15mmol, ErCl 3 0.02mmol (Y:Yb:Er=0.83:0.15:0.02), then add 6mL oleic acid and 15mL octadecene, pump the system to vacuum, stir at 70°C for 0.5h, inflate twice with argon , completely exhaust the air in the system. It was then heated to 125°C to obtain a clear solution and maintained for 45 min. Cool to room temperature.

[0068] (2) 4mmol NH 4 F and 2.5mmol NaOH were added to the above mixed solution. The system was evacuated again with an oil pump, and stirred at 70°C for 2.5 hours to obtain a clear solution. During this period, the system was inflated twice with argon to completely discharge the air in the system. Then slowly heat up to 300°C at a rate of 10°C / min, close the gas valve, and keep for 1h.

[0069] (3) After cooling down to room temperature naturally, pour it into a centrifuge tube and centrifuge at high speed (12,...

Embodiment 3

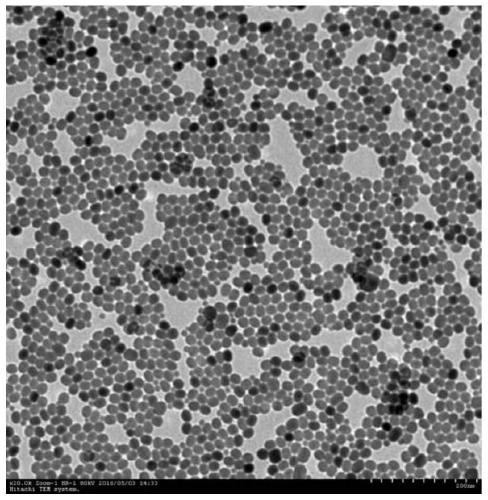

[0071] Example 3, NaYF 4 :Yb:Er@NaGdF 4 Preparation of single-shell nanoparticles

[0072] (1) Add YCl to a 100mL three-necked flask 3 0.83mmol, YbCl 3 0.15mmol, ErCl 3 0.02mmol (Y:Yb:Er=0.83:0.15:0.02), then add 6mL oleic acid and 15mL octadecene, pump the system to vacuum, stir at 70°C for 0.5h, inflate twice with argon, Completely remove air from the system. It was then heated to 125°C to obtain a clear solution and kept for 45min. Cool to room temperature.

[0073] (2) 4mmol NH 4 F and 2.5mmol NaOH were added to the above mixed solution. The system was evacuated again with an oil pump, and stirred at 70°C for 2.5 hours to obtain a clear solution. During this period, the system was inflated twice with argon to completely discharge the air in the system. Then slowly heat up to 300°C at a rate of 10°C / min, close the gas valve, and keep for 1h.

[0074] (3) Take out the above step (2) with a 1mL stainless steel tube syringe to obtain 1mL of the mixture, and then i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com