Device for Gradient Wrap of Yarn Hairiness

A yarn and gradient technology is applied in the field of devices for gradient wrapping yarn hairiness, which can solve the problems of yarn hairiness rebound, yarn surface hairiness winding structure relaxation, etc., so as to increase holding force, avoid fiber aggregation, and solve yarn problems The effect of thick line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

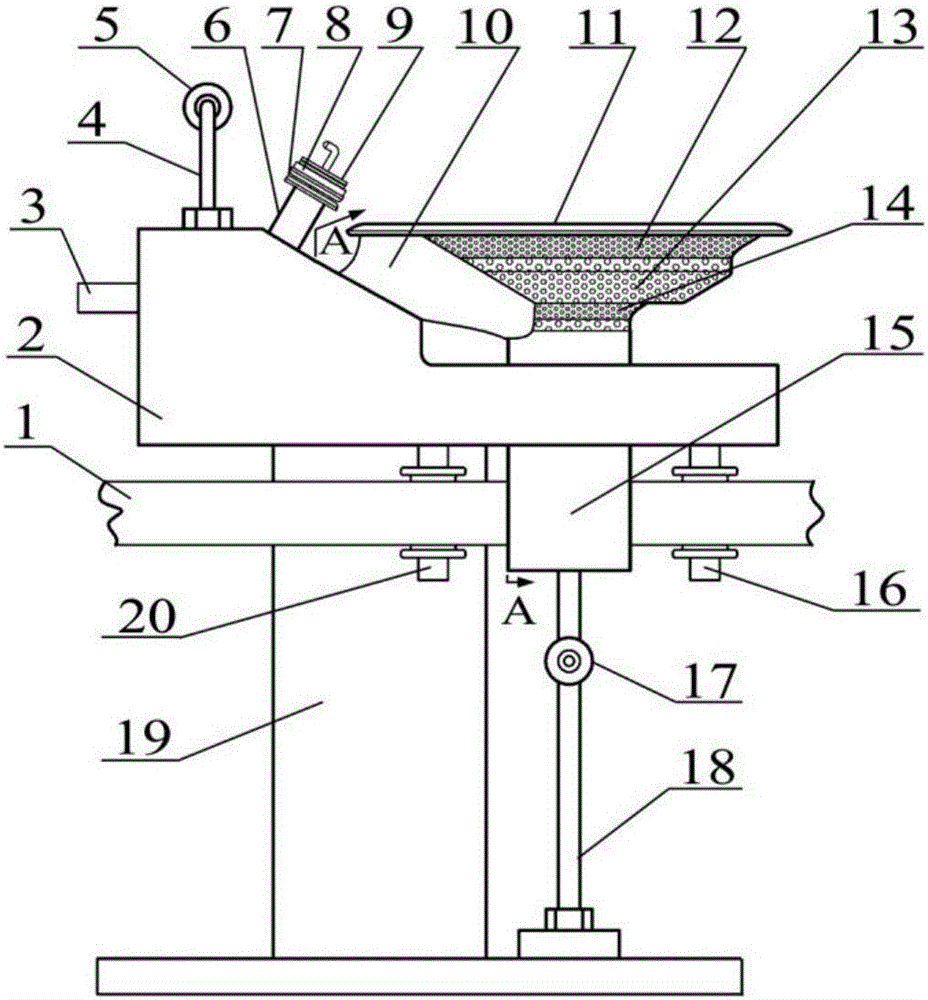

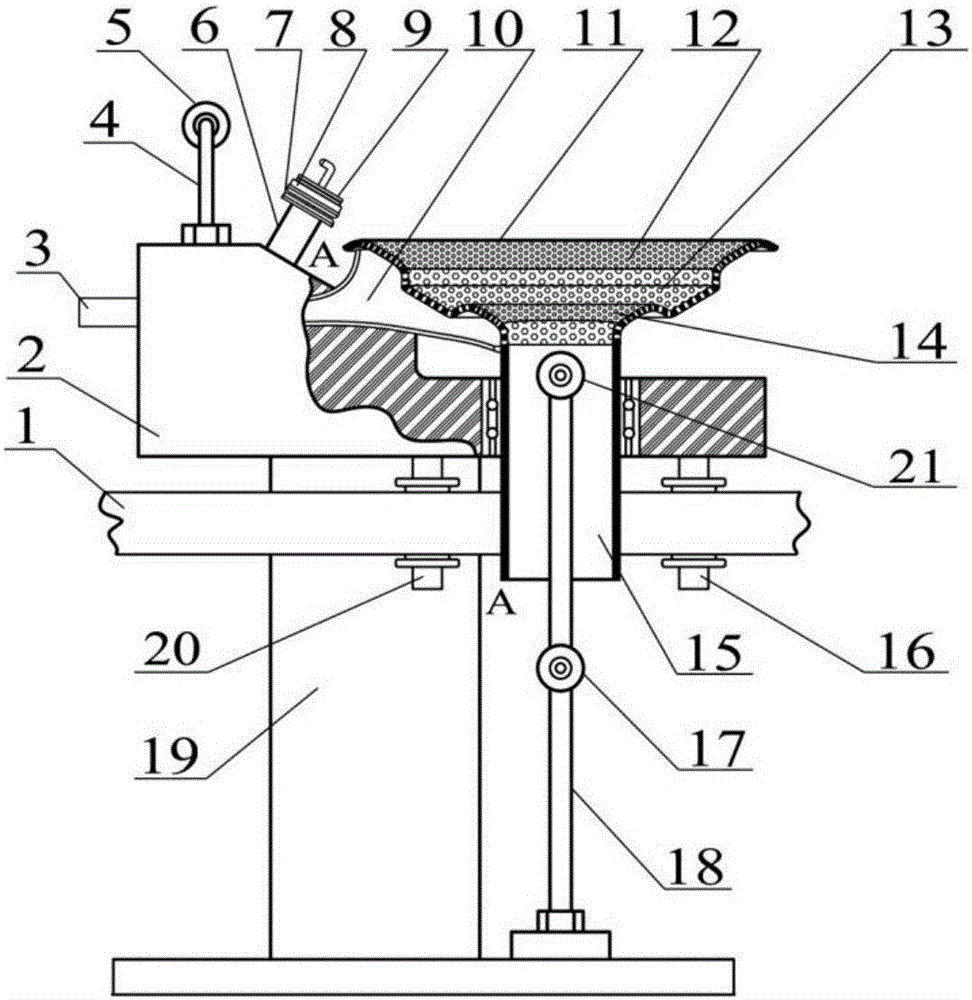

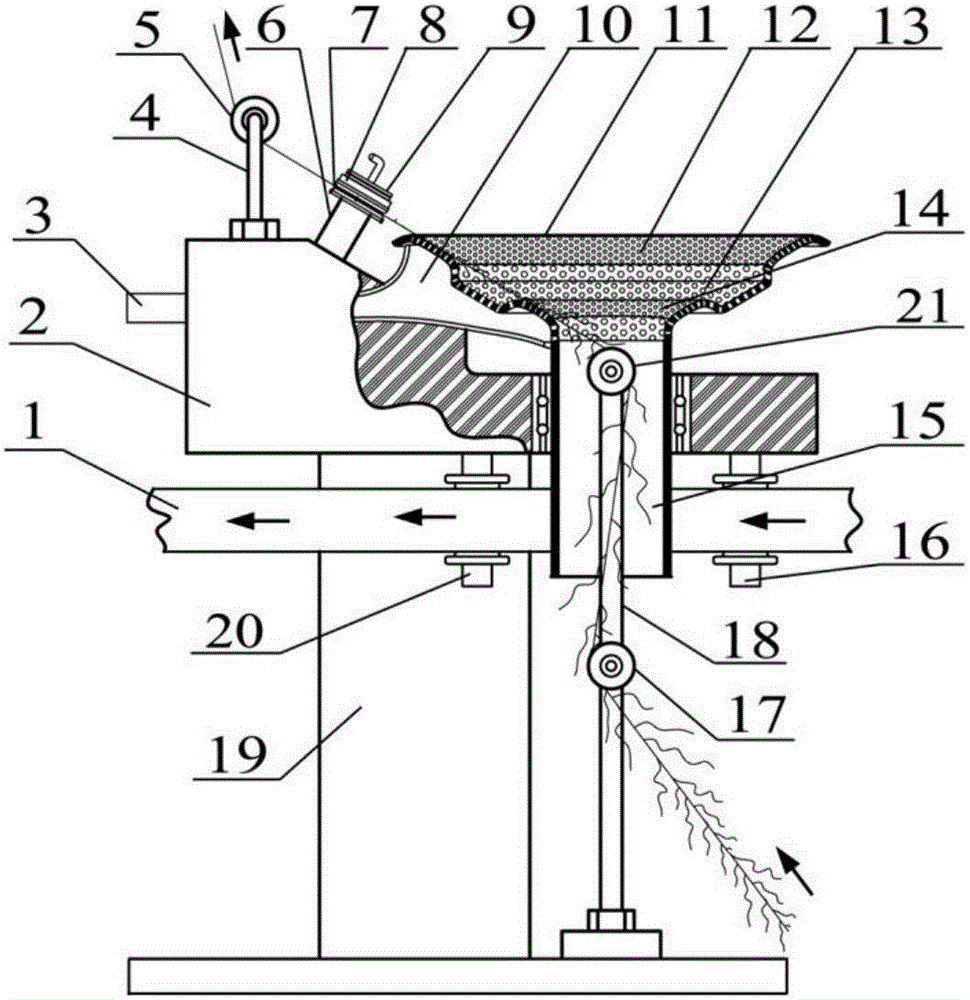

[0020] Example 1: Gradient wrapping treatment of cotton yarn hairiness in the warping process

[0021] The device of the present invention is externally connected to a drive motor through a drive belt 1, which drives the funnel-type friction device to rotate at a high speed counterclockwise at a speed of 8000 rpm, and the heat setting device is heated by an external power supply, so that the temperature of the ironing yarn trough rises to 135°C , the taper between the upper cone wall 12 and the lower cone wall 14 of the hollow cone 11 and the cross section of the hollow shaft 15 is 3:1, the upper cone wall 12 has a wall width of 20 mm, and the convex cone wall 13 has a width of 15 mm. mm, the width of the lower cone wall 14 is 10 mm, the grid through holes on all cone walls and the grid through holes on the upper end wall of the hollow shaft 15 have a diameter of 2 mm, and the outlet end 3 of the directional suction pipe is externally connected to a negative pressure exhaust fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com