An inner container component and a clothes dryer provided with the inner container component

A technology of liners and components, applied in the field of clothes dryers, can solve the problems of low heat source drying efficiency, potential safety hazards, and long drying time, and achieve the effects of saving post-processing, fast speed, and stable frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

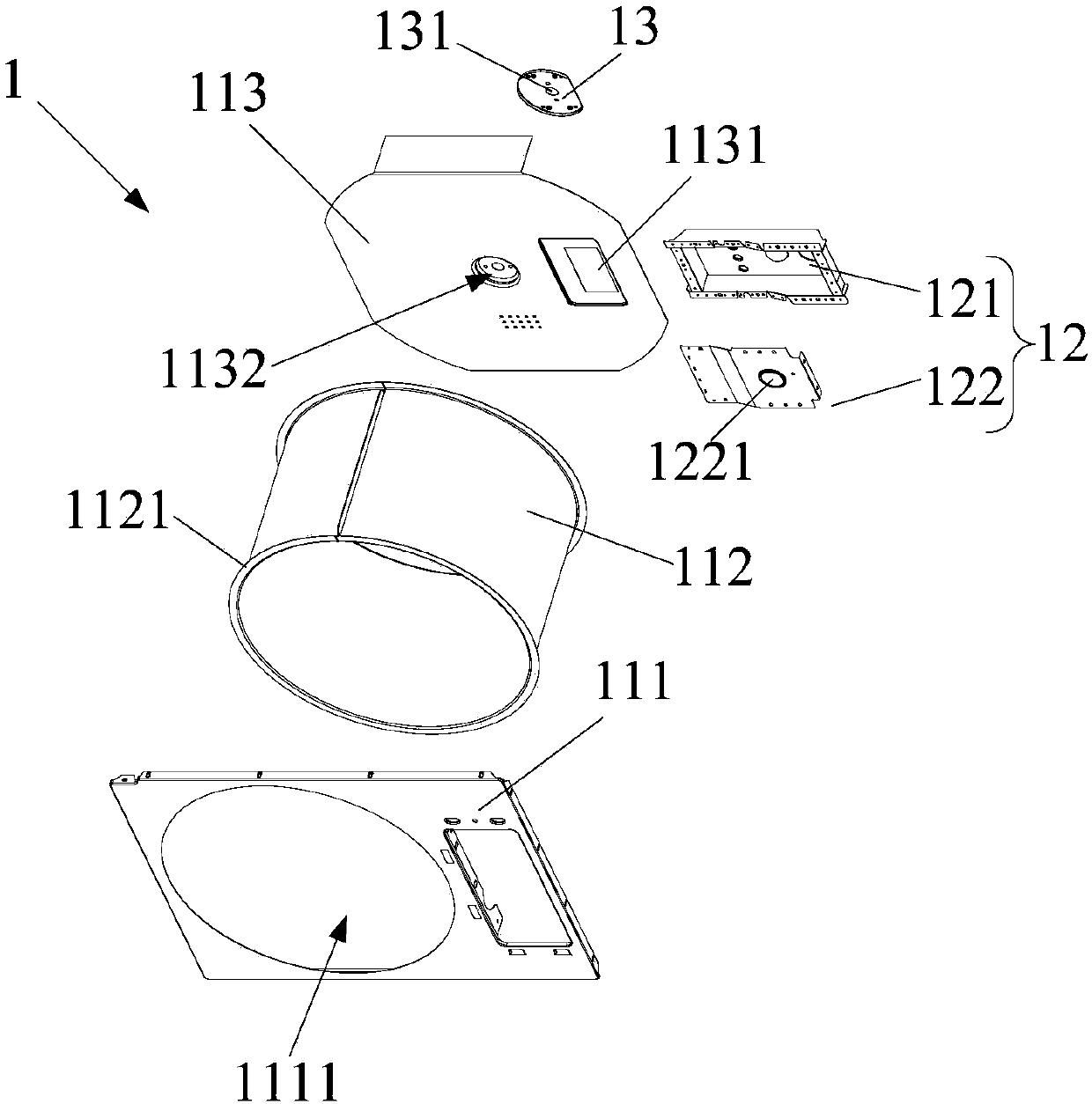

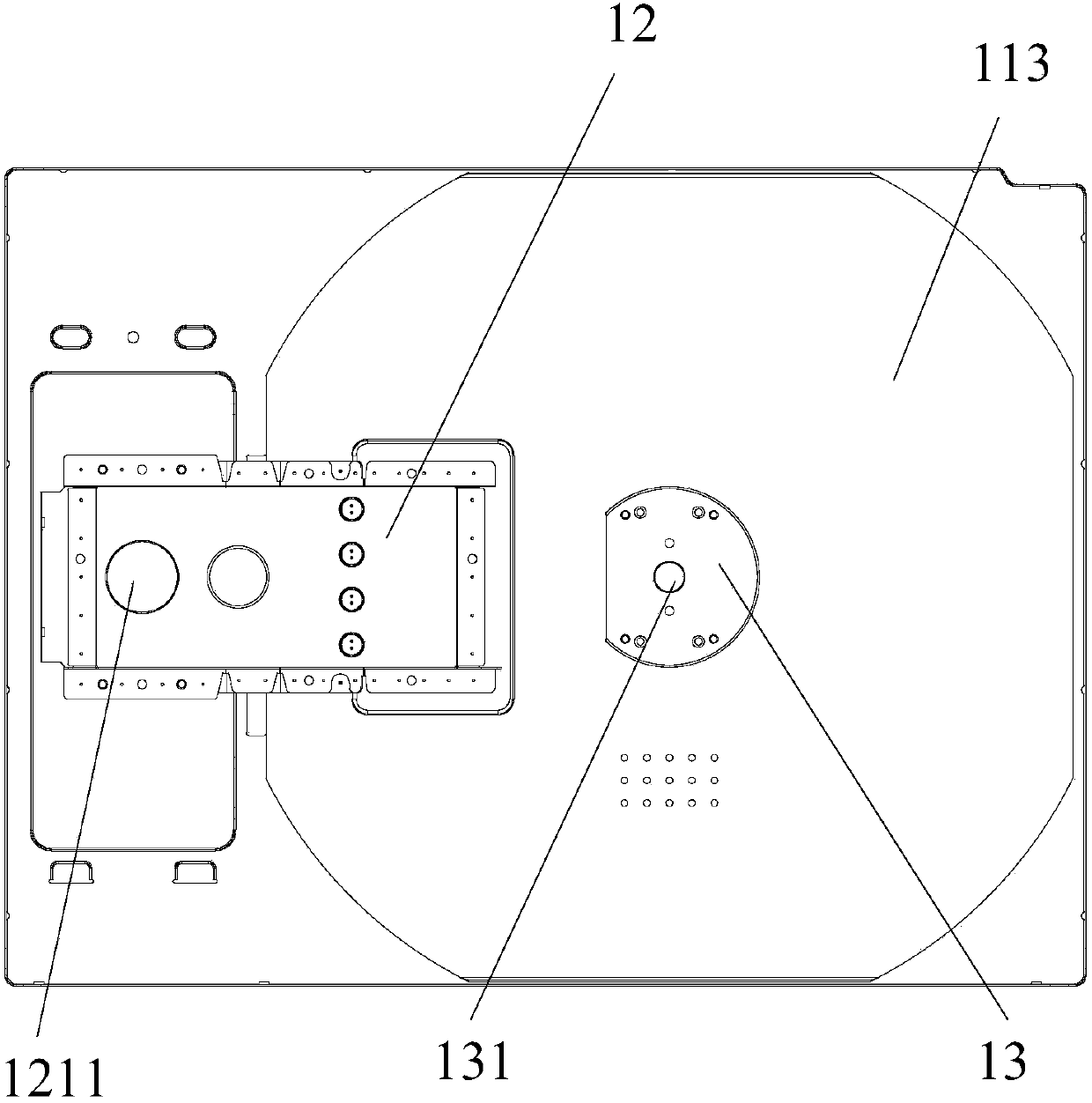

[0035] Such as Figure 2 to Figure 7 As shown, the liner assembly 1 provided in this embodiment includes a waveguide 12 and a liner body 11 with an open front end. A receiving cavity with an open front end is formed in the liner body 11. A waveguide port 1131 is provided on the liner body 11. , the entrance 1211 of the waveguide 12 communicates with the microwave emission end of the magnetron, and the exit 1221 of the waveguide 12 communicates with the accommodation cavity through the waveguide port 1131; wherein, as image 3 and Figure 4 As shown, the waveguide 12 includes a tube body 121 and a cover body 122, and the cover body 122 covers the tube body 121 and forms a guide cavity between the tube body 121; the inlet 1211 is located at On the tube body 121, the outlet 1221 is arranged on the cover 122, and both the inlet 1211 and the outlet 1221 are in communication with the guide cavity, and the waveguide 12 converts the magnetron generated The electromagnetic wave is gu...

Embodiment 2

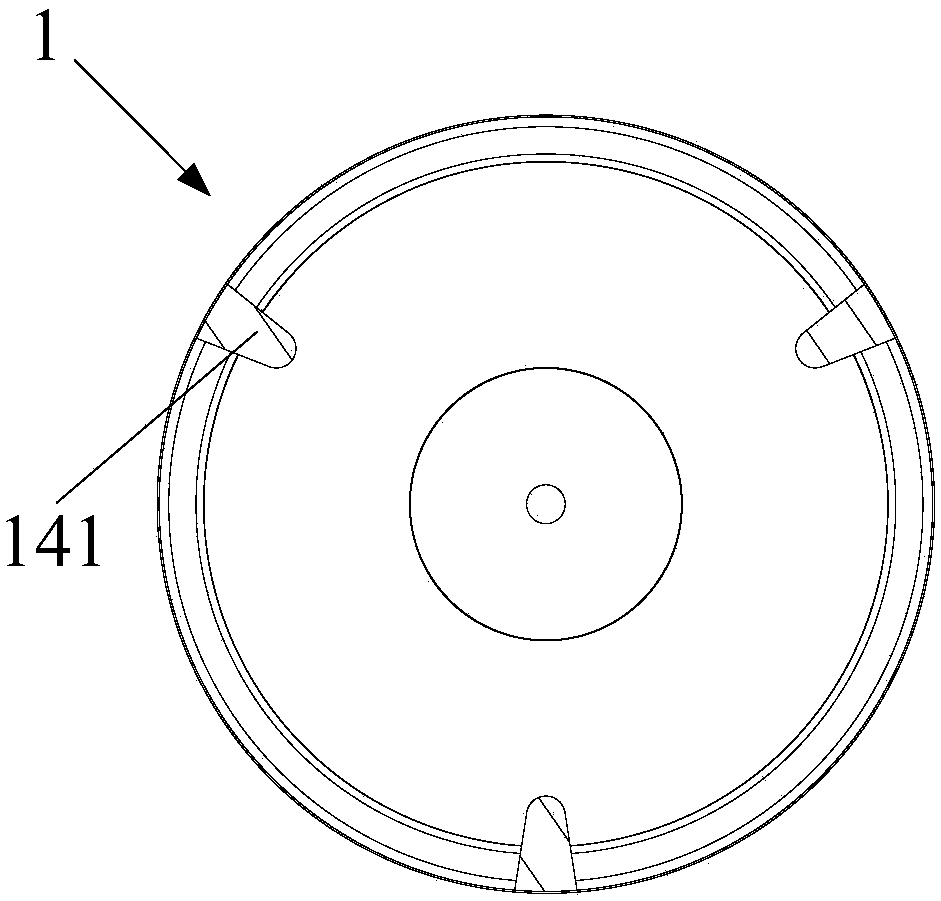

[0047] Such as Figure 8 As shown, the technical solution of this embodiment is substantially the same as that of Embodiment 1, and the main difference is that the liner body 11 in this embodiment is an integrated structure, that is, the side plate 112 and the bottom plate 142 are made of metal materials Integral stretching and forming constitutes a metal cylinder-like structure. The metal cylinder is a stretched hardware piece produced by oil pressure. The diameter of the metal cylinder gradually increases from the back to the front. The front plate 111 is welded on the The front end of the side plate 112, the rear end of the liner body 11 is provided with a recessed area 1132, the rear end of the mounting plate 1423 is provided with a protrusion 1426 that matches the recessed area 1132, and the inner diameter of the recessed area 1132 is larger than The outer diameter of the protrusion 1426, the stirring frame 14 is not in contact with the inner wall of the liner body 11, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com