Municipal pipeline dredging vehicle

A technology for municipal pipelines and dredging vehicles, applied in the field of municipal pipeline dredging and dredging vehicles, can solve the problems of low work efficiency, easy secondary pollution, inability to completely dredging and dredging, etc., and achieves the effect of improving construction efficiency and reducing secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

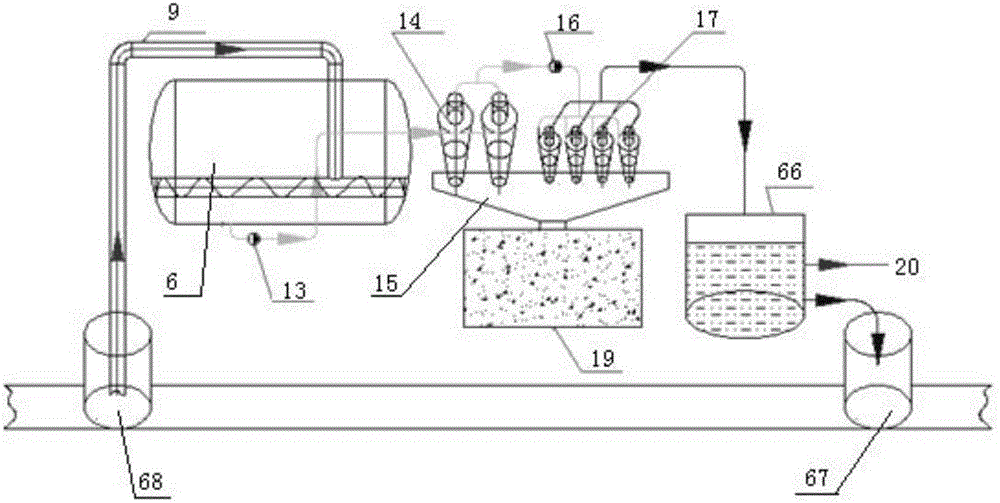

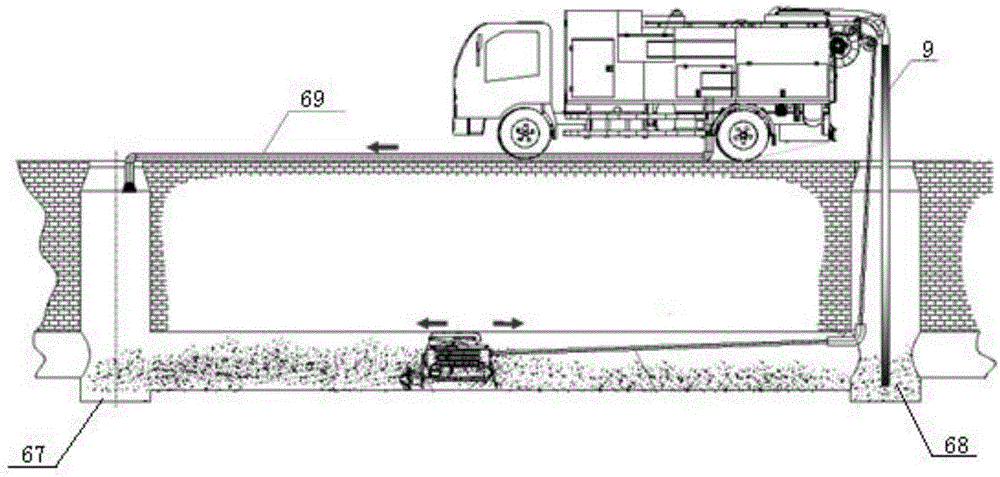

[0028] Such as figure 1 , figure 2 As shown, the general scheme of the present invention is that the pipeline robot advances to mill the sludge, or washes the sludge under high pressure, and scrapes the sludge in the horizontal pipeline to the downstream inspection shaft when it retreats. The sludge is sucked into the vacuum tank 6 by means of vacuum suction, and then the mud-water mixture is discharged to the solid-liquid separation system through the submerged sewage pump 13 for solid-liquid separation. The separated solids are temporarily stored in the storage hopper 19 for loading and unloading. Part of the treated sewage is supplied to the high-pressure flushing system, and the rest is discharged into the sewer.

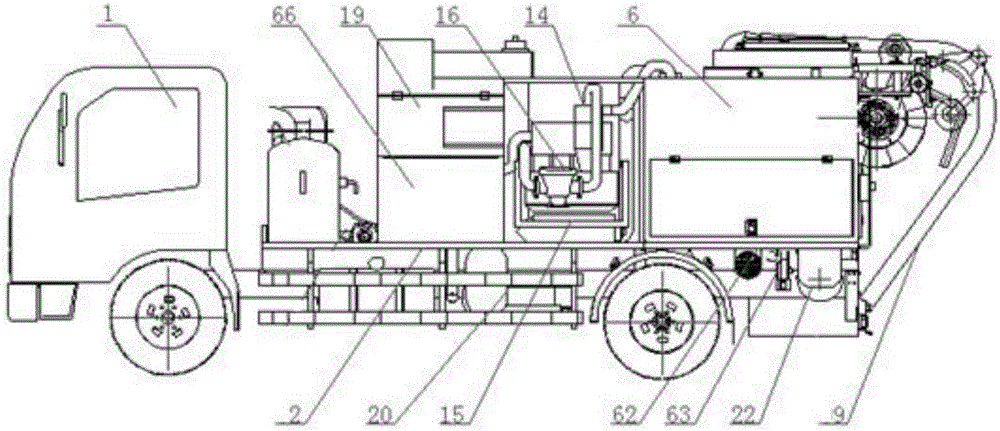

[0029] Such as image 3 , Figure 4 Shown, a kind of municipal pipeline dredging vehicle, comprises automobile chassis 1 and is installed on the subframe 2 on automobile chassis 1, also includes:

[0030] The pipeline robot is used to break up and clean the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com