Impeller, centrifugal pump and electric drive pump

A technology of impellers and blades, applied in the field of impellers, can solve the problems of small impeller diameter, small volume, small overall size of centrifugal pumps, etc., and achieve the effect of improving hydraulic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

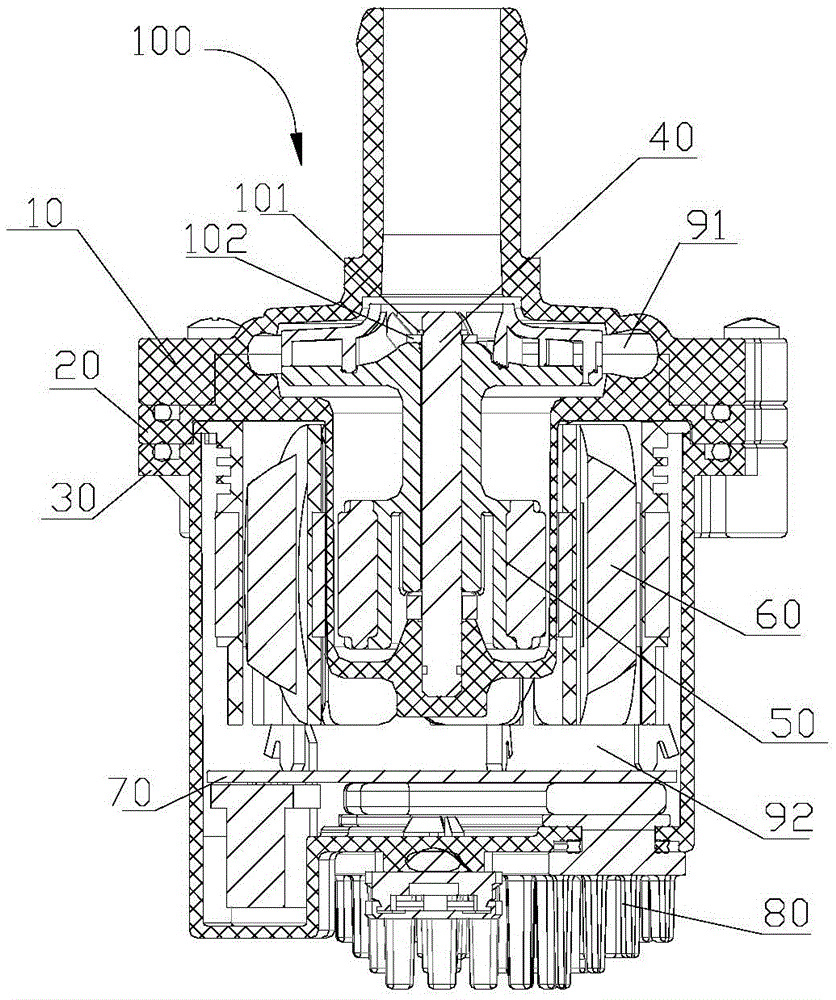

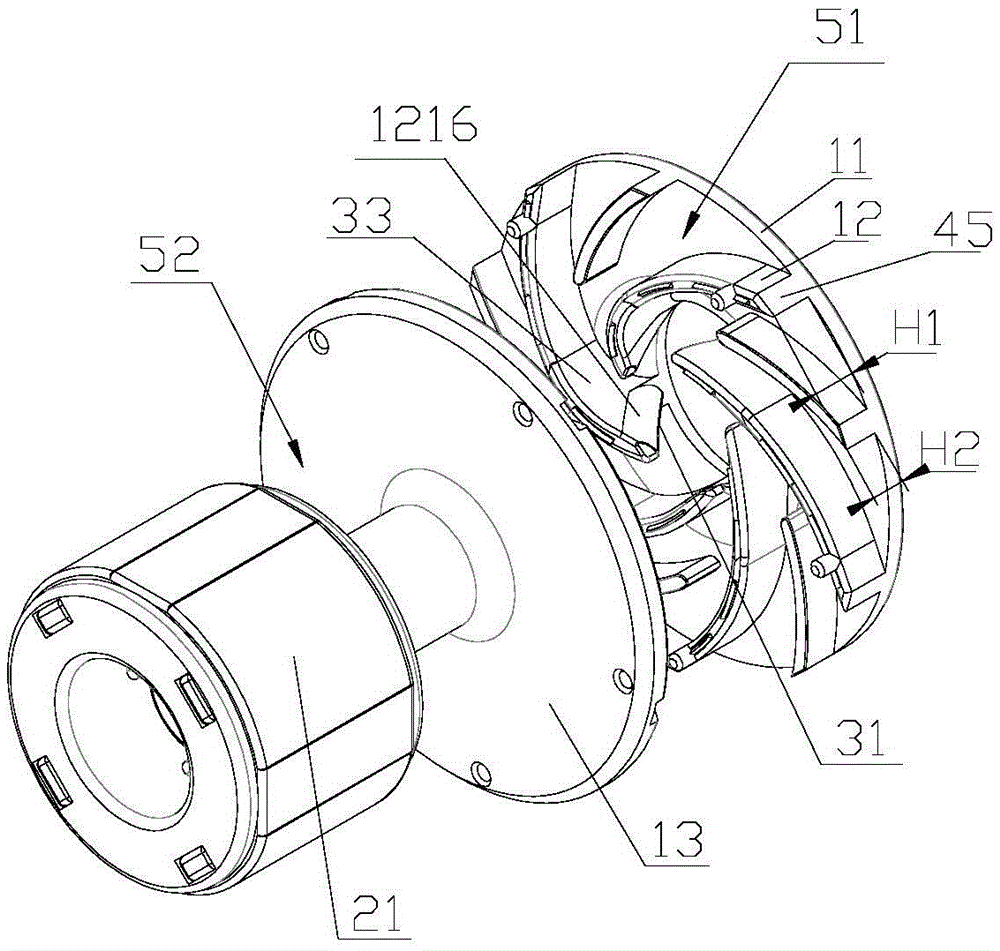

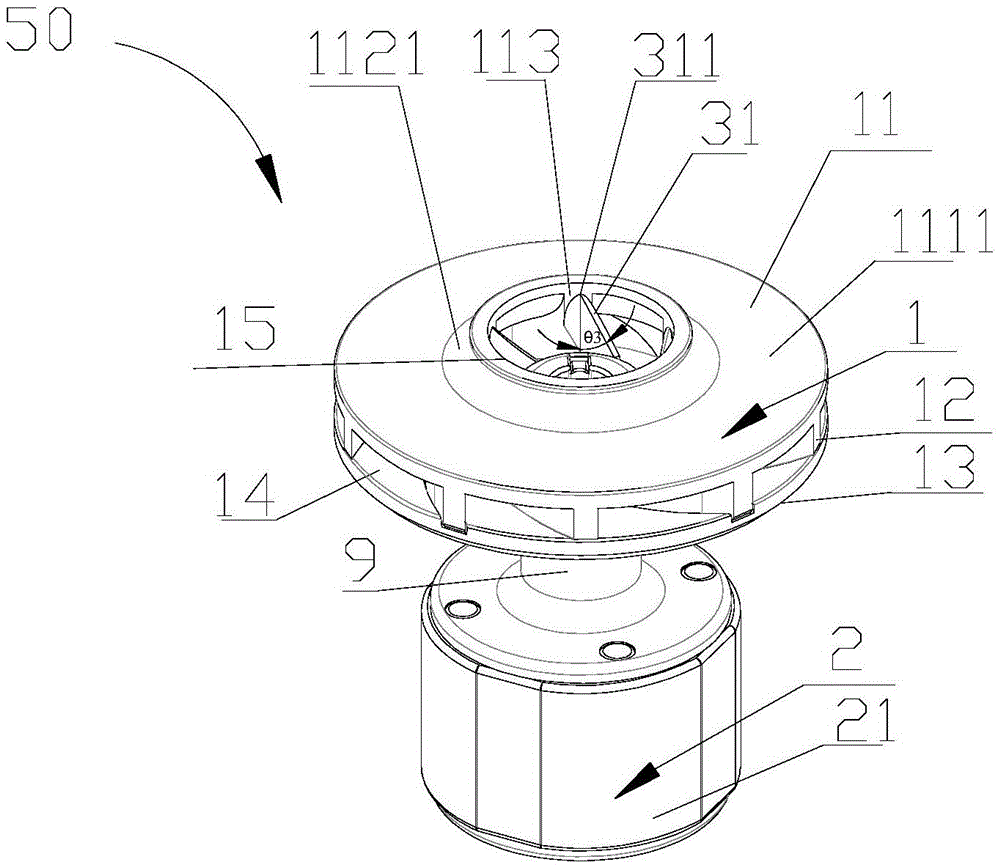

[0044] figure 1It is a structural schematic diagram of an electric drive pump 100, which includes an impeller chamber cover 10, an isolation sleeve 20, a motor housing 30, a pump shaft 40, a rotor assembly 50, a stator assembly 60, an electric control board 70, and a cooling assembly 80; the inner chamber of the pump includes the space between the impeller chamber cover 10 and the motor housing 30, and the spacer sleeve 20 divides the inner chamber of the pump into a flow chamber 91 and an accommodating chamber 92. The flow chamber 91 can have a working medium flowing through it, and the rotor The component 50 is set in the flow cavity 91, the cavity 92 has no working medium, the stator component 60 and the electric control board 70 are set in the cavity 92; the pump shaft 40 and the isolation sleeve 20 are fixed by injection molding, and the rotor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com