Solar flat-plate collector

A solar panel and collector technology, which is applied to solar collectors, solar thermal energy, and solar collectors using working fluids, etc. and other problems, to achieve the effect of improving heat collection efficiency, superior thermal insulation performance, and inhibiting convective heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

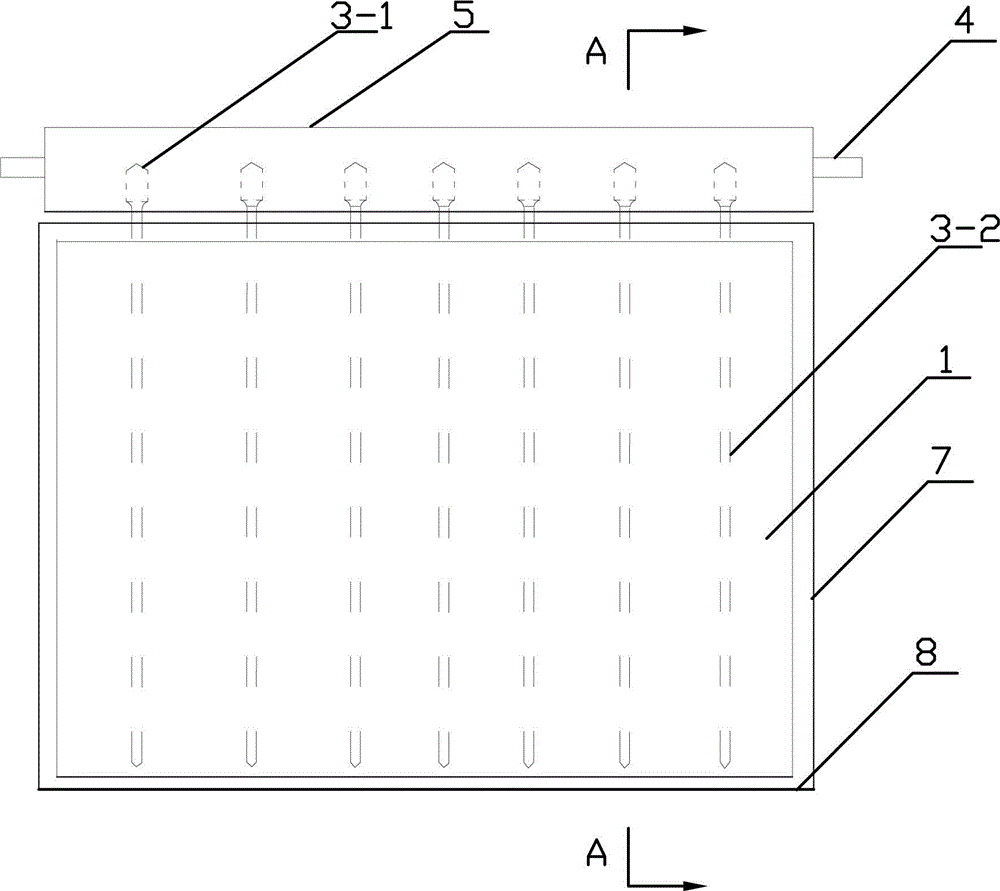

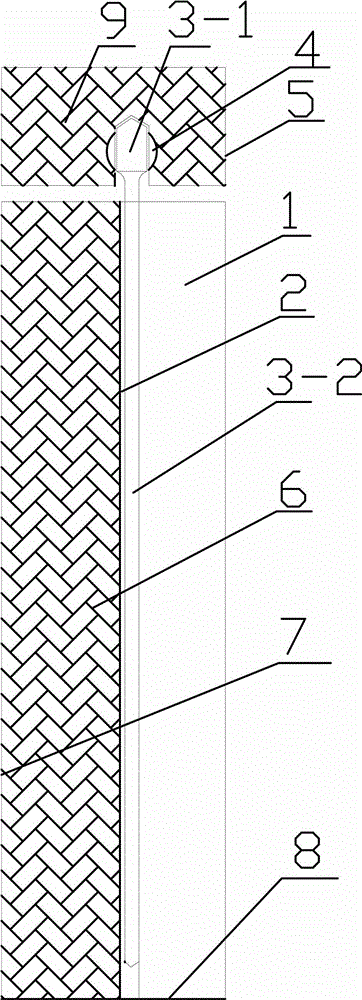

[0021] Such as Figure 1-2 As shown, a solar flat panel heat collector, the cover plate 1 is provided with a bottom plate 7 at a relative position, a bracket 8 is provided between the cover plate 1 and the bottom plate 7, and the bracket 8 forms a cavity with the cover plate 1 and the bottom plate 7 , a header 5 is provided above the cavity, a heating plate 2 is installed in the cavity, a first insulation layer 6 is provided between one side of the heating plate 2 and the bottom plate 7, and the other side of the heating plate 2 is provided with A plurality of parallel copper heat pipes, the evaporation section 3-2 of the copper heat pipe is connected to the heating plate 2, the condensation section 3-1 of the copper heat pipe is arranged in the header 5, the condensation section 3-1 of the copper heat pipe is connected to the flow channel 4 The pipe wall is in full contact, the flow channel 4 passes through the cavity of the header 5, and the gap in the cavity of the header 5...

Embodiment 2

[0027] As for the solar panel heat collector described in Embodiment 1, the material of the cover plate is hollow glass.

Embodiment 3

[0029] In the solar panel heat collector described in Embodiment 1, one side of the inner surface of the vacuum glass is coated with an infrared reflective film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com