Thermal shock furnace

A technology of thermal shock and furnace, which is applied in the field of thermal shock resistance experiment, can solve the problems affecting the accuracy and authenticity of the test results, and achieve the effect of simple structure, fast unloading and reducing operation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further defined below in conjunction with the accompanying drawings and specific embodiments.

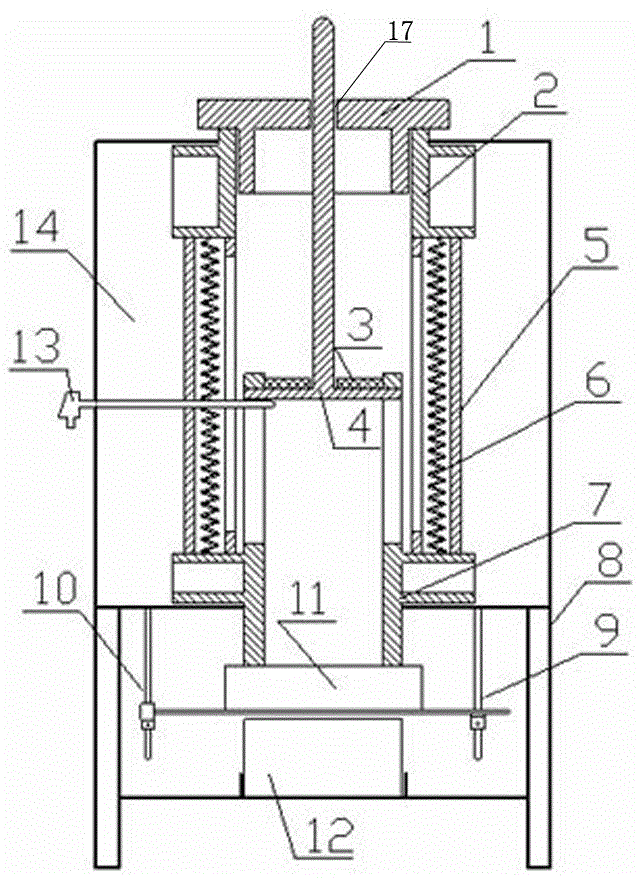

[0023] Such as figure 1 As shown, a thermal shock furnace includes a furnace shell 8, a furnace 5 positioned on the furnace shell 8, and a heating element 6 located in the furnace 5. A barrier sleeve 7 is arranged in the furnace 5, and the sleeve part of the barrier sleeve 7 Inserted into the furnace 5, the fence part of the fence sleeve 7 is located below the furnace 5.

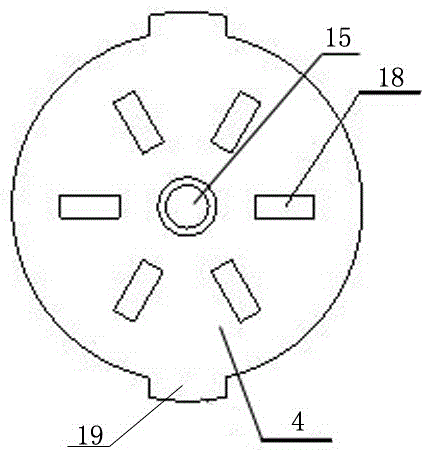

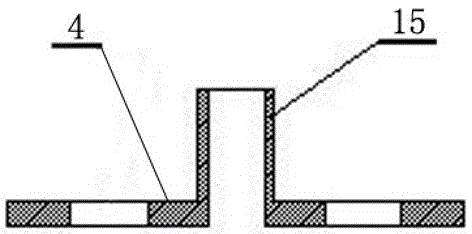

[0024] A sample heating chamber is formed inside the furnace 5, and the upper sample tray 3 and the lower sample tray 4 are arranged up and down in the sample heating chamber, grooves are opened on the top side wall of the fence sleeve, and lugs 19 are provided on the upper and lower sample trays. , The lugs 19 on the upper and lower sample trays are located in the grooves on the top side wall of the fence sleeve. The center of the upper sample tray 3 is provided with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com