One-shot forming manufacturing process for single-beam-tube longitudinally-wrapped-water-blocking-tape cable sheath and product thereof

A manufacturing process and technology of water-blocking tape, applied in the one-time molding manufacturing process of optical cable sheath and its products, can solve the problems of reducing the production efficiency of optical cables, improving the turnaround period of semi-finished products and manufacturing costs, and difficult to strictly control product quality. Achieve the effect of streamlining equipment, reducing turnaround time and manufacturing cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

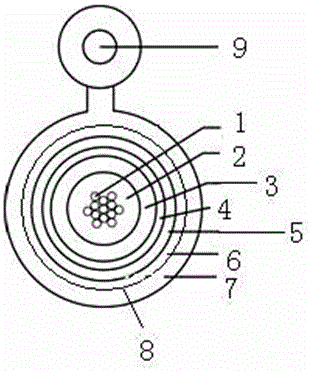

[0019] Embodiment: single-bundle tube adds water-blocking tape vertically wrapped optical cable sheath one-time forming manufacturing process, and this process comprises the following steps successively:

[0020] a. Color the optical fiber first;

[0021] b. The optical fiber is made into a bundle tube by the plastic coating process, and then 8 water-blocking glass fiber yarns are wrapped outside the tube tube; casing.

[0022] c. Then wrap the water-blocking tape vertically outside the water-blocking glass fiber yarn;

[0023] d. Then realize the one-time molding of yarn binding, tearing rope and sheath outside the water blocking belt, and complete the manufacture of optical cable. In this step, the above functions are realized by installing a yarn binding machine capable of winding binding yarn and tearing rope on the processing sheathing equipment, and through human control, the one-time binding of yarn binding and sheathing after the water blocking tape is wrapped longit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com