Flexible display panel, its preparation method, and flexible display device

A flexible display and flexible substrate technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as drift, contact hole and channel area wear signals, poor display, etc., to reduce Effects of stress variation, reduced wear, and improved overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

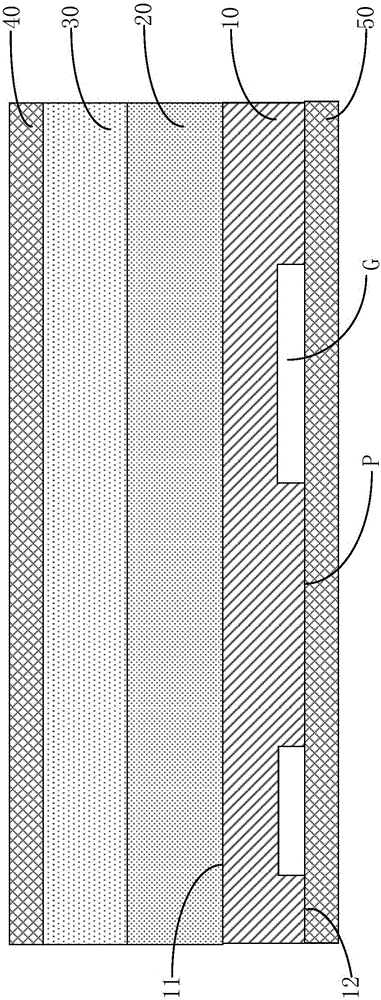

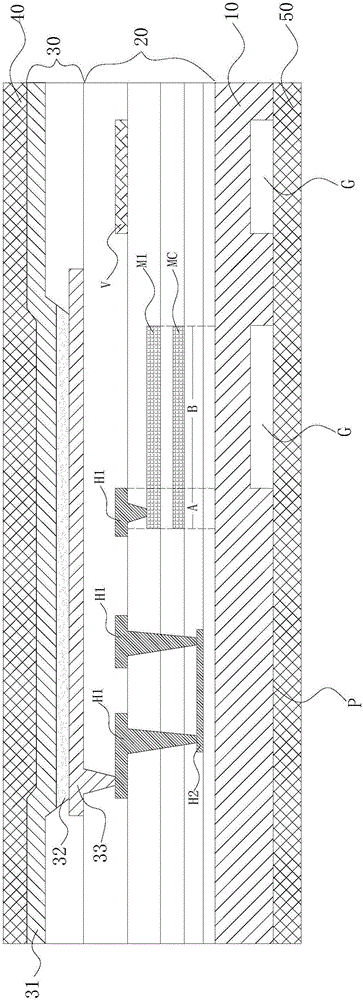

[0032] Such as figure 1 and figure 2 As shown, two schematic cross-sectional views of a flexible display panel provided by Embodiment 1 of the present invention, wherein figure 1 It is a schematic cross-sectional view of one part of the flexible display panel, which only roughly shows the basic structural composition; figure 2 It is a detailed cross-sectional schematic diagram of another part of the flexible display panel.

[0033] Such as figure 1 As shown, the flexible display panel of Embodiment 1 includes: a flexible substrate 10 , a TFT array layer 20 , a display layer 30 , a front protective film 40 and a rear protective film 50 .

[0034] Wherein, the flexible substrate 10 has a first surface 11 and a second surface 12; wherein, the first surface 11 is figure 1 As shown on the upper surface of the flexible substrate 10, the second surface 12 is figure 1 The lower surface of the flexible substrate 10 is shown.

[0035] In this embodiment, the flexible substrate 1...

Embodiment 2

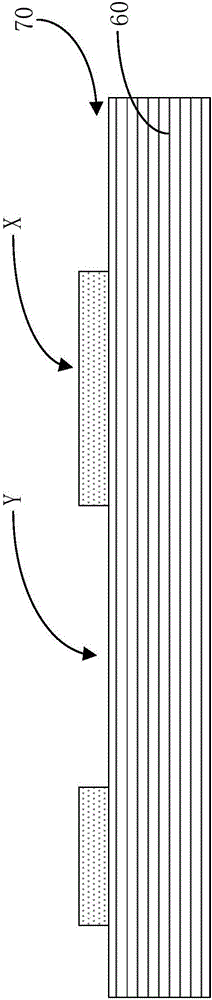

[0082] like Figure 7 As shown, the schematic cross-sectional view of the flexible display panel of Embodiment 2, the difference between the flexible display panel of Embodiment 2 and Embodiment 1 lies in the structure of the flexible substrate 10 .

[0083] The flexible substrate 10 of Example 2 has a structure in which multiple layers of flexible substrate films 10a are stacked in sequence.

[0084] In a specific embodiment of the present invention, the flexible substrate film 10a can use conventional flexible substrate materials such as PI or PET.

[0085] In Embodiment 2, the flexible substrate 10 is formed by stacking multiple layers of PI films sequentially; Figure 7 As shown, the PI film forming the second surface 12 is the lowermost PI film.

[0086] The second surface 12 of the flexible substrate 10 (the lower surface of the lowermost PI film) has a concave-convex patterned structure, which is the same as that of Embodiment 1, and details will not be repeated here....

Embodiment 3

[0088] like Figure 8 As shown, a schematic cross-sectional view of the flexible display panel of Embodiment 3, the difference between the flexible display panel of Embodiment 3 and Embodiment 1 lies in the structure of the flexible substrate 10 .

[0089] The flexible substrate 10 of the third embodiment has a structure in which flexible substrate films 10a and inorganic films 10b are alternately stacked, and the first surface 11 and the second surface 12 are formed by the flexible substrate films 10a.

[0090] In a specific embodiment of the present invention, the flexible substrate film 10a can use conventional flexible substrate materials such as PI or PET; the inorganic film 10b can be made of silicon oxide or nitrogen oxide.

[0091] In Example 3, the flexible substrate film 10a is a PI film, and the inorganic film 10b is a silicon oxide film.

[0092] The second surface 12 of the flexible substrate 10 (the lowermost flexible substrate film 10 a ) has a concave-convex p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com