Four-station detection and cutting device for chip resistors

A cutting device and detection device technology, which is applied in the direction of manufacturing tools, metal processing equipment, optical testing flaws/defects, etc., can solve the problem of insufficient appearance accuracy of the inspected chip resistance, affecting the quality and function of the finished product, unstable quality of the chip resistance, etc. problems, to achieve low daily maintenance costs, reduce eye fatigue, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

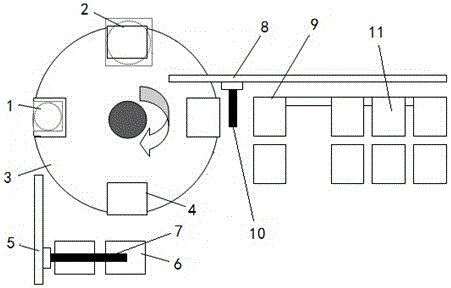

[0012] Attached below figure 1 The present invention will be further explained. Attached figure 1 It schematically shows the four-station detection and cutting device for chip resistors of the present invention, including an automatic control device, a feeding device, a detection device 1, a cutting device 2 and a receiving device, and is characterized in that it also includes a rotatable four-station The four-station disk 3 is uniformly fixed on the edge of the four-station disk 3 with four positioning clamps 4, and the four positioning clamps 4 are sequentially provided with matching feeding devices, detection devices 1, cutting devices 2, and receiving devices. The inspection device 1 is equipped with an industrial inspection camera, and the cutting device 2 is equipped with a laser.

[0013] Preferably, the four positioning fixtures 4 are provided with sensors.

[0014] Preferably, the feeding device includes a feeding guide rail 5 and a double feeding bin 6. A slidable feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com