Novel jig for wok polishing

A new type of pot and fixture technology, which is applied in the direction of grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve the influence of the texture of the pot billet, the inability to guarantee the consistency of the speed of the pot billet and the speed of the roller or profiling fixture, and the uncertain positioning of the pot center And other problems, to achieve the effect of firm suction pot, reduce the risk of workers' work, and reduce shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

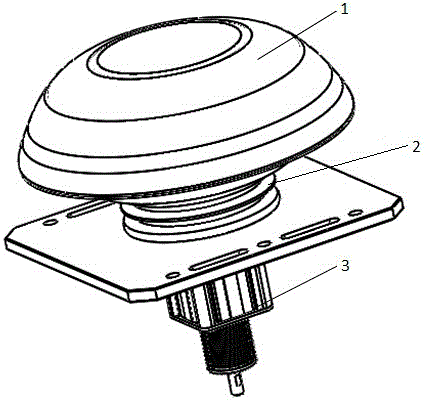

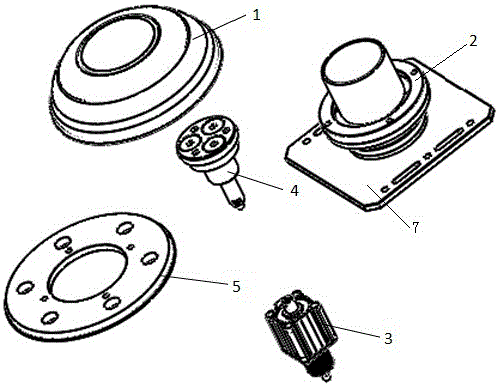

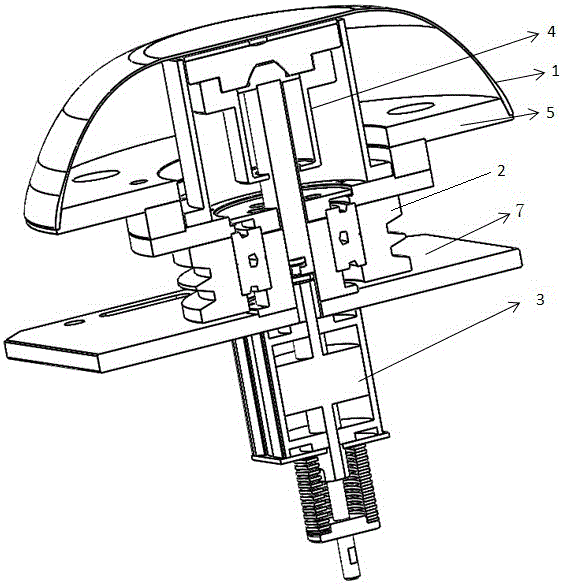

Embodiment 1

[0039] As shown in the figure, the novel pot polishing fixture of the present embodiment includes a base 7, a rotating mechanism 2, a pan grinding fixture, an aligning mechanism 4, and a cylinder 3 connected to the base 7, and the rotating mechanism 2 is arranged on the base 7 And the rotating mechanism 2 can rotate relative to the base 7 . Wherein, the pan grinding jig includes a pan profiling jig 6 for grinding the inner surface of the pan 1 , and an outer surface jig 5 for grinding the outer surface of the pan 1 . The outer surface clamp 5 is annular, and the outer diameter of the outer surface clamp 5 is the same as the opening size of the pot blank 1 .

[0040] The centering mechanism 4 includes a centering bracket 8, a magnet 9, a heat insulating pad 10, and a centering connecting rod 11 connected with the centering bracket 8. The heat insulating pad 10 and the magnet 9 are arranged on the centering bracket 8 respectively, and the cylinder 3 passes through The centering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com