Automatic warehousing system

A warehousing system and mobile platform technology, applied in the field of warehousing, can solve the problems that robots cannot complete path planning, robots cannot complete docking tasks according to pre-set paths, and are not pre-set, so as to ensure safe and environmentally friendly production and reduce labor costs. and the effect of cost management and accurate path planning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

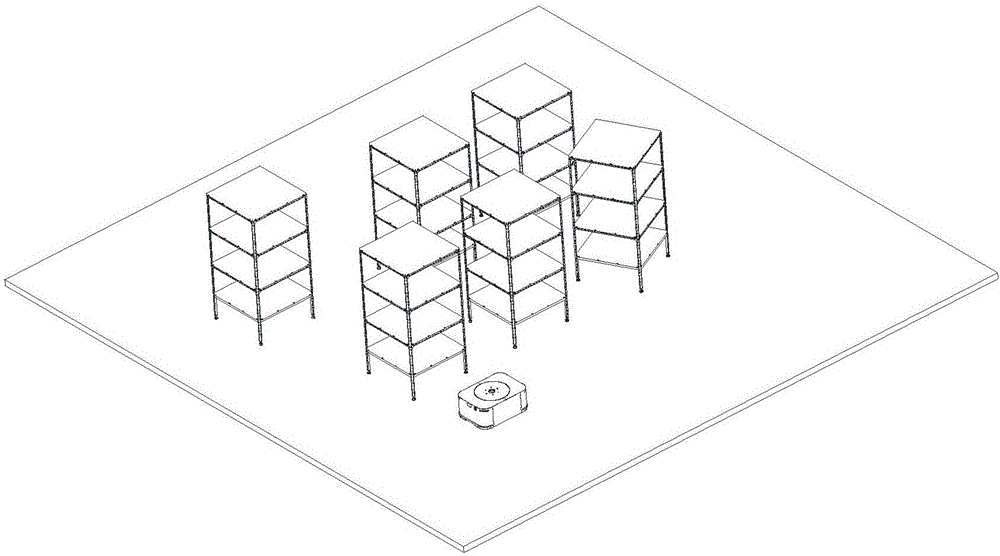

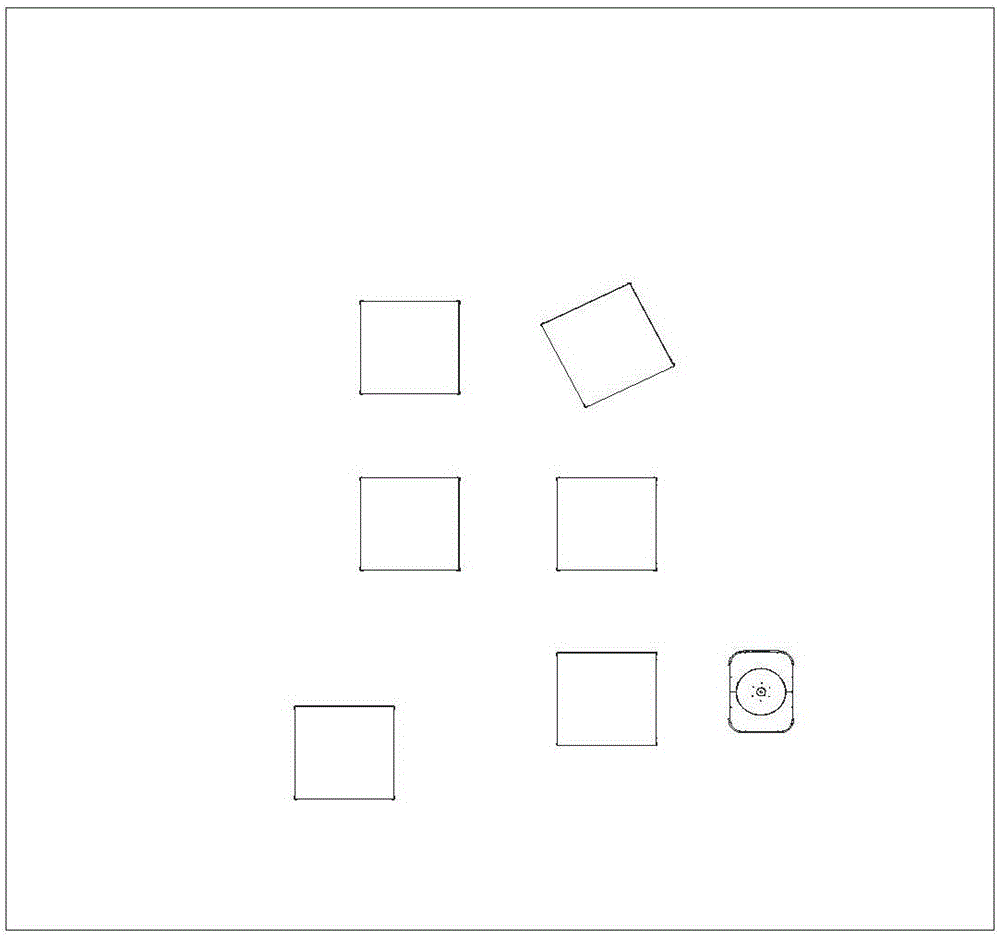

[0022] The present invention provides an automatic storage system, including a movable platform and a shelf, and the movable platform moves to a specified posture according to a planned path to connect with the shelf. The storage system includes

[0023] Obtain the unit and obtain the position of the shelf in the working environment;

[0024] The computing unit calculates and determines the specified pose of the movable platform in the environment map according to the position and direction of the shelf;

[0025] A path planning unit, which uses a path planning algorithm to generate a path for the movable platform to move from the current position to the specified pose;

[0026] The drive control unit of the movable platform controls the movable platform to move along the path to a specified pose.

[0027] Wherein, the movable platform and the shelf of the present invention are located in the working environment of the storage system. The working environment includes a workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com