Screw type conveyor

A conveyor and screw-type technology, applied in the field of cargo conveying equipment, can solve the problems of unusable small production workshops, single running direction, and large space occupation, and achieve the effects of small space occupation, fast transportation speed, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with specific embodiments.

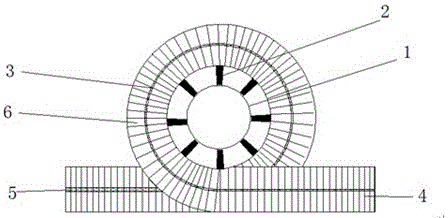

[0018] The screw conveyor proposed by the present invention includes a fixing device and a guiding system. The fixing device includes a fixing column 1 at the center of the equipment and a support column at the bottom. The spacing of the fixed rods 2 is the same, the guide system includes a motor and a guide rail, the guide rail is fixed on the fixed rod 2, and is in a spiral shape, and the upper end of the guide rail is provided with a high-level material inlet and outlet 4, and the lower end is provided with a low-level material inlet and outlet 5 , the surface is provided with a chain plate 6, both sides are provided with guardrails, and the inside is provided with a single-row track, the chain 3 is connected inside the single-row track, and the top of the chain 3 is fixed on the chain plate 6 in parallel, under the action of the motor The chain 3 runs and drives the cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com