Methods for preparing graphene and graphene composite from artificial diamond

A technology for artificial diamond and composite materials, applied in the field of preparing graphene and its composite materials, can solve problems such as restricting the development of olefin alloys, and achieve the effects of saving raw materials, promoting development, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

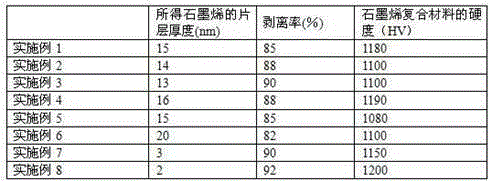

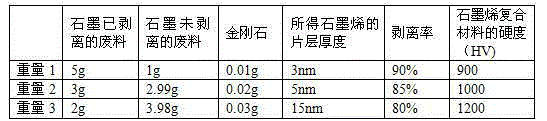

Examples

Embodiment 1

[0046] Add 350ml of water into the high-speed homogenizer, and then add the above-mentioned 8g of synthetic diamond waste, and homogenize at room temperature for 2 hours at a homogenization speed of 100r / min.

Embodiment 2

[0048] Add 350ml of water into the high-speed homogenizer, and then add the above-mentioned 8g of synthetic diamond waste, and homogenize for 2 hours at a homogenization speed of 5000r / min at room temperature.

Embodiment 3

[0050] Add 400ml of ethanol to the high-energy ball mill, and then add the above-mentioned 8g of synthetic diamond waste, ball mill for 1 h at room temperature, and then homogenize in a high-speed homogenizer for 3 h at a homogenization speed of 12,000 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com