Antibacterial and antistatic water- borne UV light curing ceramic ink jet ink and preparing method thereof

A ceramic inkjet and light curing technology, applied in the field of ceramics, can solve problems such as application limitations, human allergies or burns, short storage and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

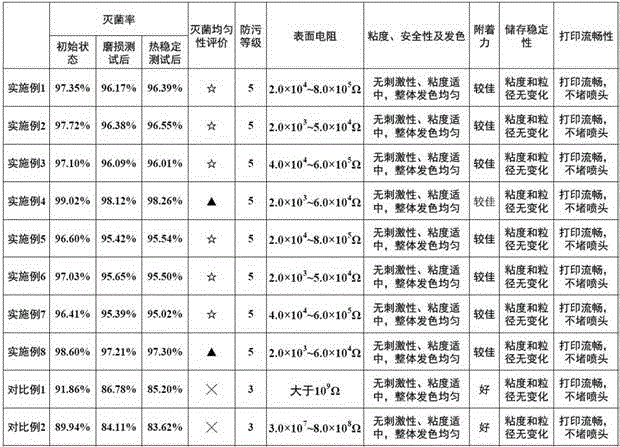

Examples

Embodiment 1

[0036] An antibacterial and antistatic water-based UV photocurable ceramic inkjet ink and a preparation method thereof, the preparation method comprising the following steps:

[0037] Step A, first mix 20% water-based acrylate, 20% ethylene glycol and 1% ink additives (0.5% Nuosperse FX9086, 0.1% Levaslip 8629, 0.2% BYK052, 0.3% Disparlon 6650) through a high-speed disperser, and then Add 38% ceramic black pigment while stirring at high speed, then double the speed, disperse at high speed for about 60 minutes, then add 18% water-based epoxy acrylate and 1% conductive filler, continue stirring at high speed until the mixture is uniform; then add 1% antibacterial compound Continue to stir at a high speed until the mixture is evenly mixed to obtain a mixed material;

[0038] Step B. Preliminary sand-milling and dispersing of the mixed material through a ball mill, and then transferred to a sand mill for further sand-milling and dispersing until the fineness of the ceramic pigment...

Embodiment 2

[0050] An antibacterial and antistatic water-based UV photocurable ceramic inkjet ink and a preparation method thereof, the preparation method comprising the following steps:

[0051] Step A. First mix 24% water-based acrylate, 15% ethylene glycol and 2% ink additives (0.5% Nuosperse FX9086, 0.5% Levaslip 8629, 0.5% BYK052, 0.5% Disparlon 6650) through a high-speed disperser, and then Add 29% ceramic black pigment while stirring at high speed, then double the speed, disperse at high speed for about 60 minutes, then add 20% water-based epoxy acrylate and 5% conductive filler, continue stirring at high speed until the mixture is uniform; then add 3% antibacterial compound Continue to stir at a high speed until the mixture is evenly mixed to obtain a mixed material;

[0052] Step B. Preliminary sand-milling and dispersing of the mixed material through a ball mill, and then transferred to a sand mill for further sand-milling and dispersing until the fineness of the ceramic pigment...

Embodiment 3

[0064] An antibacterial and antistatic water-based UV photocurable ceramic inkjet ink and a preparation method thereof, the preparation method comprising the following steps:

[0065] Step A, first mix 30% water-based acrylate, 12% ethylene glycol and 3% ink additives (1% Nuosperse FX9086, 0.3% Levaslip 8629, 0.9% BYK052, 0.8% Disparlon 6650) through a high-speed disperser, and then Add 28% ceramic black pigment while stirring at high speed, then double the speed, disperse at high speed for about 60 minutes, then add 10% water-based epoxy acrylate and 8% conductive filler, continue stirring at high speed until the mixture is uniform; then add 5% antibacterial compound Continue to stir at a high speed until the mixture is evenly mixed to obtain a mixed material;

[0066] Step B. Preliminary sand-milling and dispersing of the mixed material through a ball mill, and then transferred to a sand mill for further sand-milling and dispersing until the fineness of the ceramic pigment t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com