Fixed point analysis method for bottom of super junction groove

An analysis method, a super technology, applied in the direction of analyzing materials, using measurement of secondary emissions for material analysis, using wave/particle radiation for material analysis, etc., can solve the problem that the grinding accuracy cannot meet the failure point positioning analysis, and the bottom of the trench cannot be solved. Problems such as fixed-point analysis and inability to judge the depth of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The fixed-point analysis method at the bottom of the superjunction trench provided by the present invention includes:

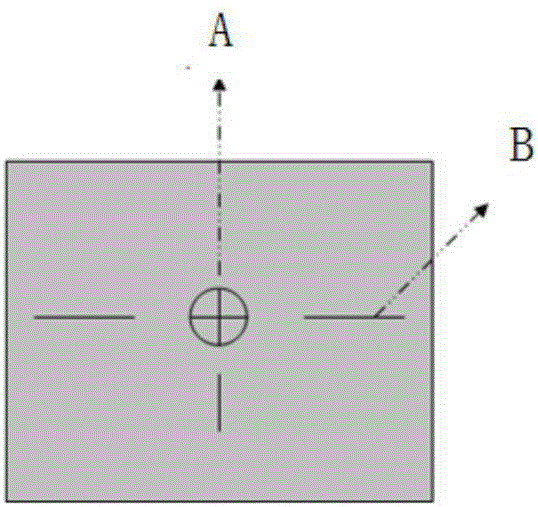

[0039] 1) if figure 1 As shown, a laser is used to make a fixed-point mark at the position where the sample needs to be analyzed; the purpose of this step is to avoid the inability to judge the location of the failure point after subsequent sample processing to avoid changes in the surface pattern.

[0040] In this embodiment, more than or equal to 4 marks are produced in this step. Taking 4 marks as an example, the shapes that can be used to make the distances between the marks equal are such as the four corners of a rhombus, the four corners of a square, or evenly distributed on a certain circle, and the distance between the marks is 10 microns to 20 microns.

[0041] The distance between the above-mentioned marks is preferably 15 microns.

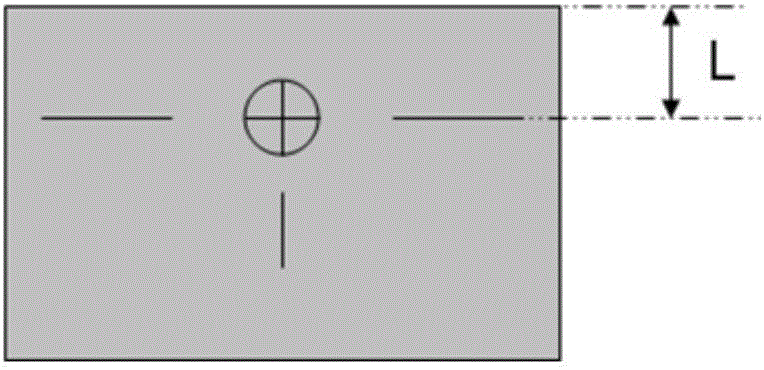

[0042] 2) if figure 2 As shown, the sample is ground on the side of the sample until the remaining sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com