Experimental method and device for simulating composite multi-layer gas reservoir exploitation

An experimental device and gas reservoir technology, which is applied in the field of simulating the exploitation of composite multi-layer gas reservoirs, can solve the problems that the original reservoir temperature conditions cannot be simulated, the liquid phase cannot be considered, and cannot be promoted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

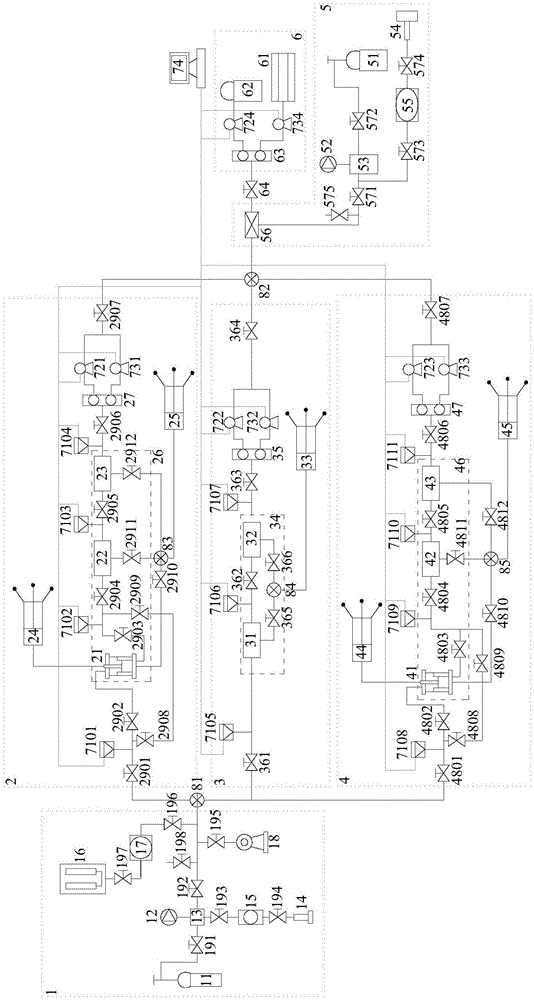

[0066] like figure 1 As shown, the present invention provides an experimental device for simulating the coalbed methane / tight sandstone gas / shale gas combined bed mining process, including an injection system 1, a coal seam model system 2, a tight sandstone layer model system 3, a shale model system 4, Back pressure system 5, recovery system 6 and data acquisition system 7.

[0067] In the injection system, the injection system is connected to the inlet valve 2901 of the coal seam model system, the inlet valve 361 of the tight sandstone layer model system, and the inlet valve 4801 of the shale model system through the first multi-channel valve (six-way valve) 81 . The high-purity methane high-pressure gas cylinder 11 is connected to the valve 191, the booster pump 13, and the gas intermediate container 15 in sequence. The high-purity methane high-pressure gas cylinder 11 provides a stable gas source for the gas intermediate container 15, and the booster pump 13 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com