Optical cable laying method for in-situ monitoring of submarine pipelines

A laying method and technology for submarine pipelines, which are applied in optical fiber/cable installation, optics, light guides, etc., can solve the problems of great influence on monitoring distance and accuracy, increase information loss of optical cable, and easy damage to optical cable, so as to avoid monitoring distance and The effect of precision, improving reliability and safety, and avoiding damage to optical cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

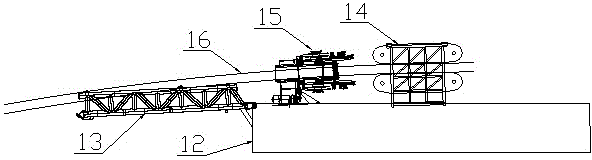

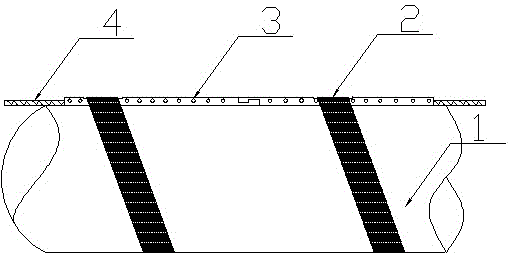

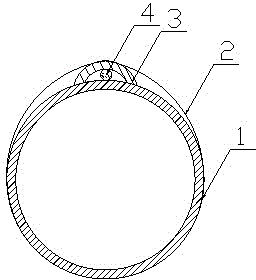

[0027] Such as Figure 1-5 As shown, the present invention is an optical cable laying method for in-situ monitoring of submarine pipelines, and the implementation steps include:

[0028] (1) After the pipe-laying ship 12 is in place, place the take-up and pay-off frame wrapped with the optical cable 4 on the rear side of the stern tensioner 14, and place the cable storage reel wrapped with several sections of optical cable sheath 3 on the take-up and pay-off stand Next, the optical cable fixing device 15 is fixed between the tensioner 14 and the stinger 13, and the steel pipe 1 to be laid is inserted into the center hole of the optical cable fixing device 15 after passing through the tensioner 14;

[0029] (2) Start the optical cable fixing device 15, pull the optical cable 4 and place it on the side of the steel pipe 1, then pull the optical cable shea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com