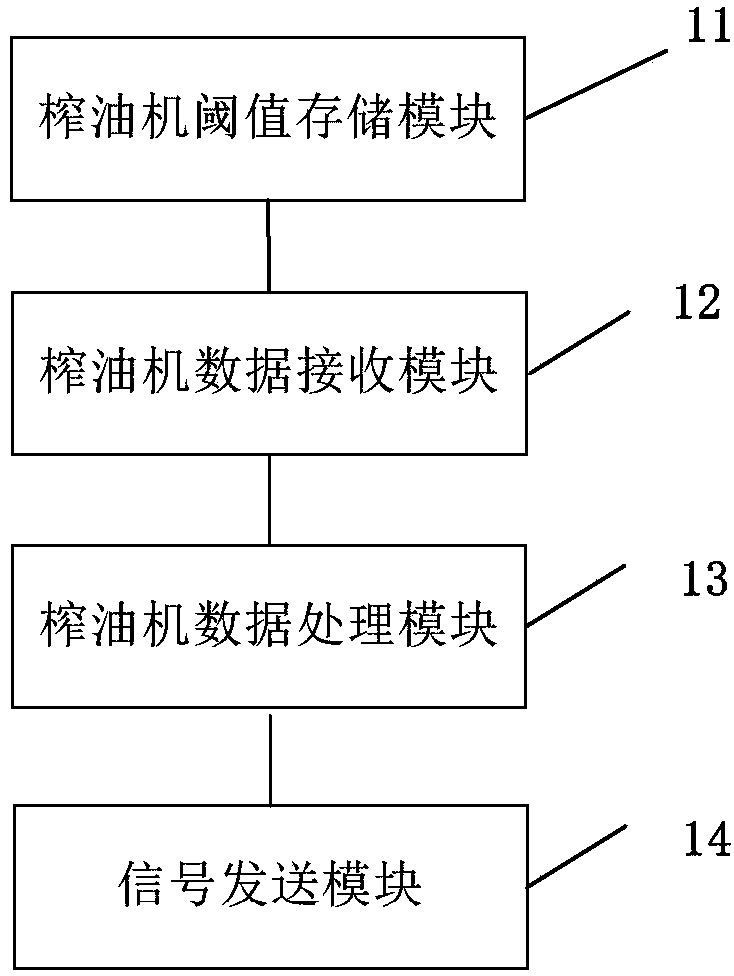

A method and system for controlling low-temperature pressing of peanuts

A control method and control system technology, applied in the field of peanut low-temperature pressing control method and system, can solve problems such as inability to operate continuously, insufficient driving force, easy formation of smooth bore, etc., and achieve the effect of facilitating continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

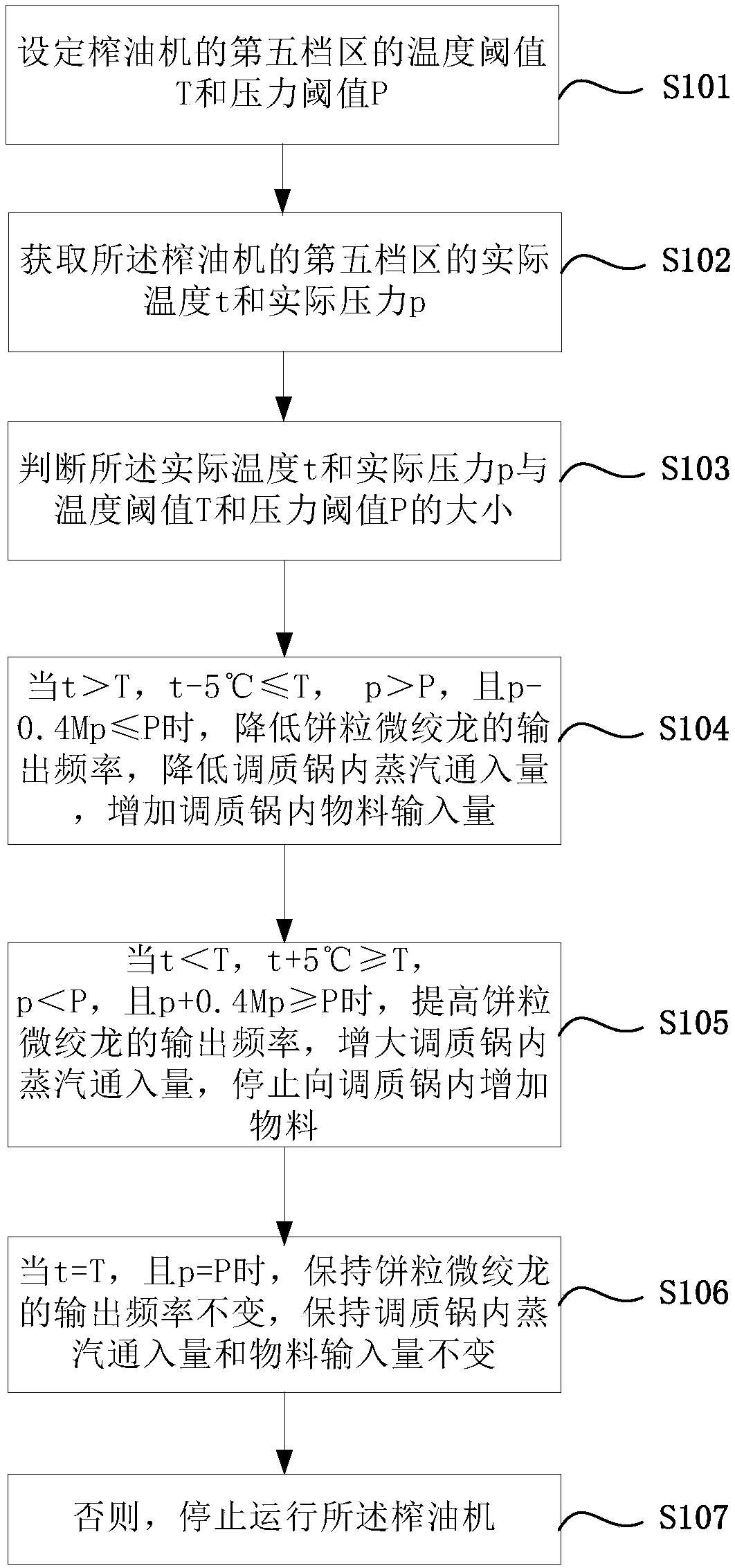

Embodiment 1

[0086] After the oil press is in normal operation, the temperature and pressure sensor on the machine chamber, such as the temperature and pressure sensor pt02a-10-6p, measures the temperature in the machine chamber as 76°C and the pressure value as 2.8Mpa; the temperature controller on the tempering pot, For example, the temperature measured by the temperature controller CB401 is 62°C. At this time, the oil press normally feeds half grains after conditioning, and the output frequency of the micro-screwed dragon inverter that adds cake grains is 26Hz; after half an hour of normal operation of the oil press, The temperature and pressure sensor measured the temperature inside the machine chamber as 79°C, and the pressure value was 3.2Mpa. The temperature controller on the tempering pot measured the temperature as 64°C. The frequency becomes 23Hz, the opening degree of the steam regulating valve JHZAZ2 becomes smaller, the amount of steam input in the tempering pot becomes smaller...

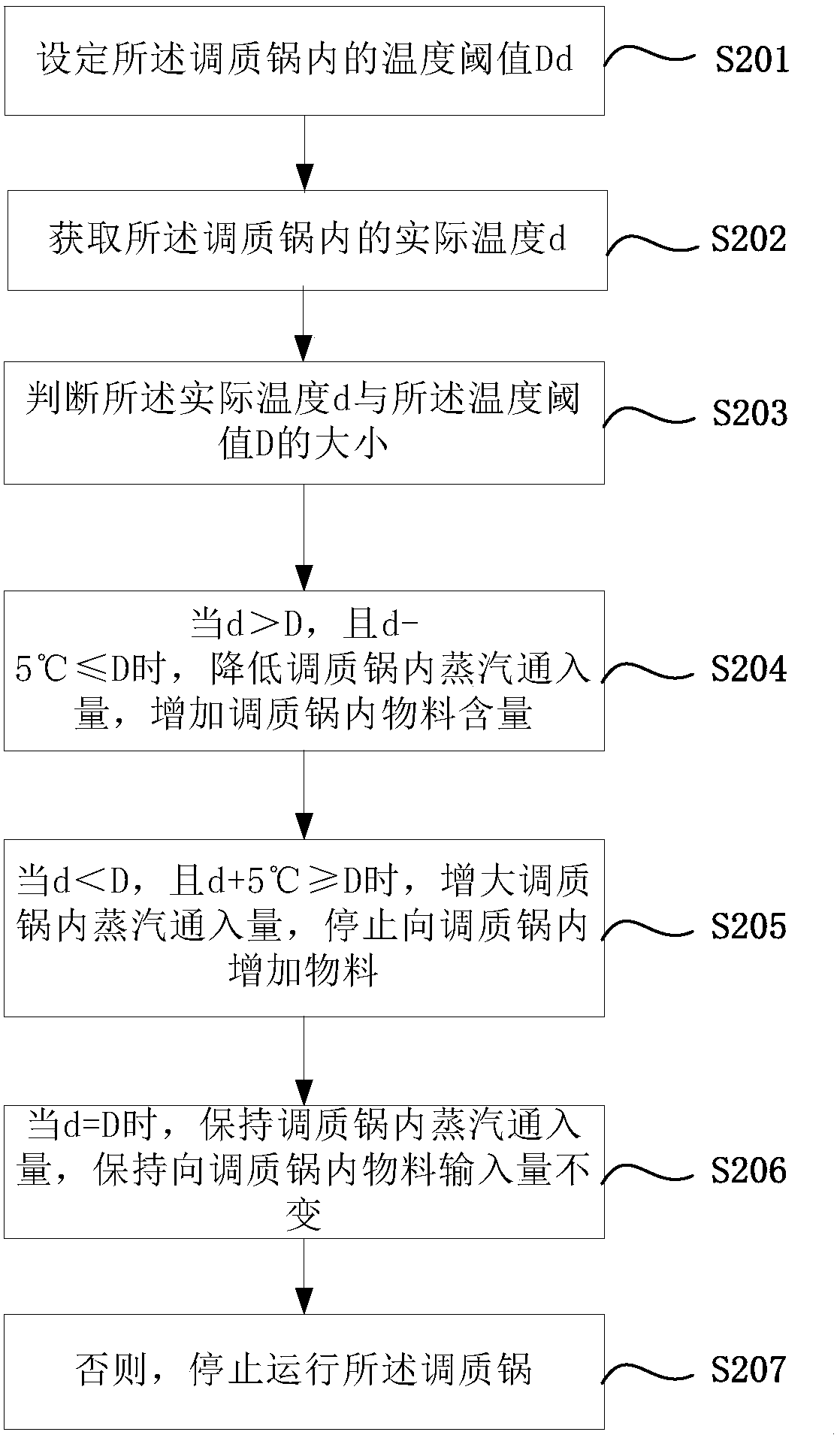

Embodiment 2

[0088] After the oil press is in normal operation, the temperature and pressure sensor on the machine chamber, such as the temperature and pressure sensor pt02a-10-6p, measures the temperature in the machine chamber as 71°C and the pressure value as 2.6Mpa; the temperature controller CB401 on the tempering pot The measured temperature is 58°C. At this time, the oil press normally feeds half grains after conditioning, and the output frequency of the micro-screw inverter that adds cake grains is 25Hz; after half an hour of normal operation of the oil press, the temperature and pressure sensor measures The temperature inside the machine chamber is 69°C, the pressure value is 2.5Mpa, and the temperature measured by the temperature controller on the tempering pot is 55°C. The valve opening degree of the regulating valve JHZAZ2 becomes larger, and the amount of steam input in the tempering pot becomes larger, and the flow rate is 215 kg / hour. When the material level switch on the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com