Allocation design method for stiffness on different position of fixed joint surface of machine

A technology of fixed joint surface and parameter allocation, applied in the direction of design optimization/simulation, calculation, genetic law, etc., can solve the problems of inability to meet production requirements, difficulty in ensuring the dynamic characteristics of the machine tool with stiffness parameters, and time-consuming, so as to improve the performance. Processing efficiency and processing accuracy, strong operability, and the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

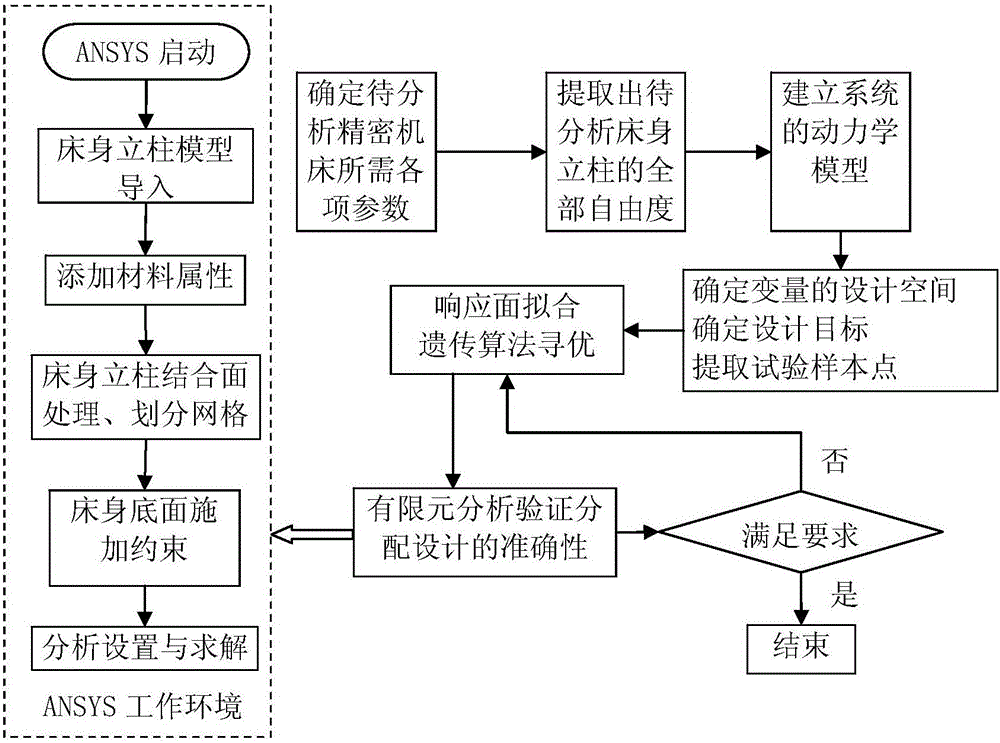

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings, figure 1 It is the overall flowchart of the inventive method, and the design method step for specific embodiment is as follows:

[0022] (1) Determine the parameters required for the precision machine tool to be analyzed

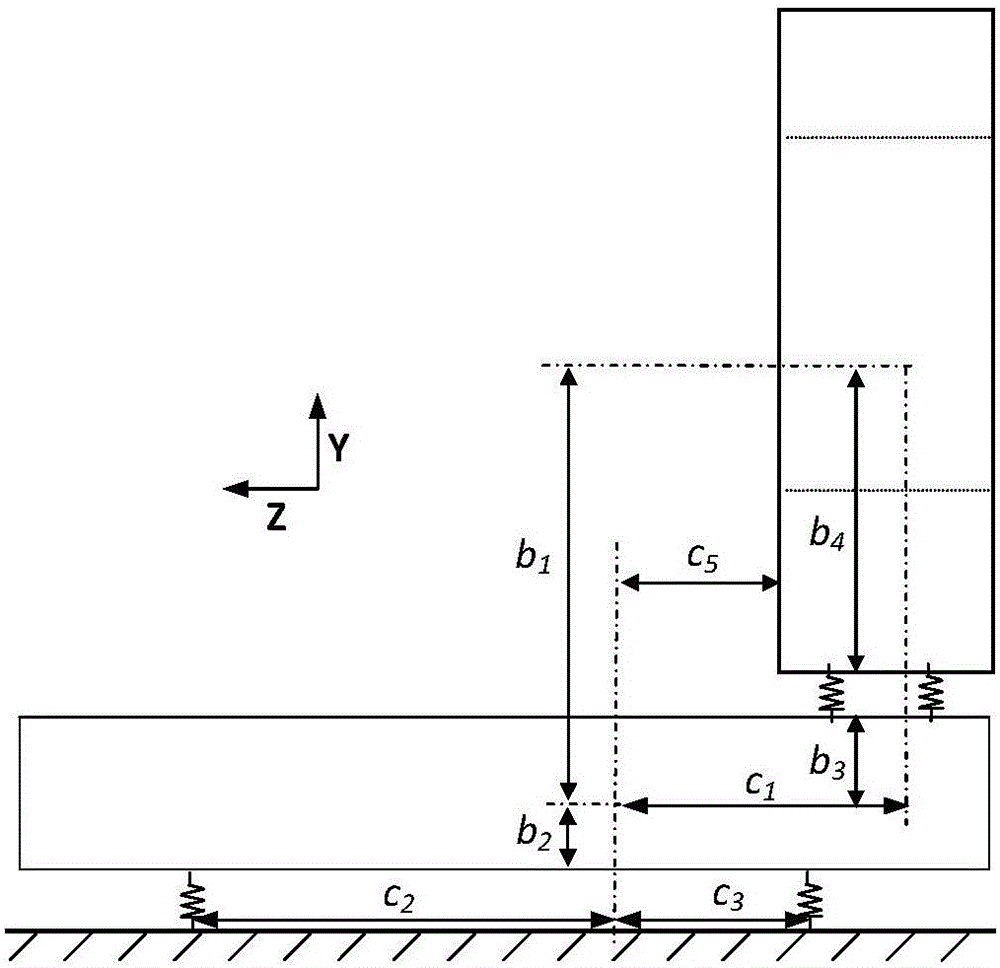

[0023] The various parameters required for the precision machine tool to be analyzed are the outer dimensions of the bed column, the relative position dimensions of the connection points of the joint surface, the quality parameters and the moment of inertia parameters of the bed column. The required geometric parameters of the bed column and joint surface to be analyzed are as follows: figure 2 As shown, the relative position size of the connection point of the combined surface is a 3 、a 4 、a 5 、c 4 、c 6 、c 7 、c 8 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com