Compound contact with higher welding resistance and high arc burning loss resistance

An arc burn-resistant, composite contact technology, used in circuit breaker contacts, circuit breaker parts, etc., can solve the problems of high resistivity, high price of silver alloy contacts, and temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

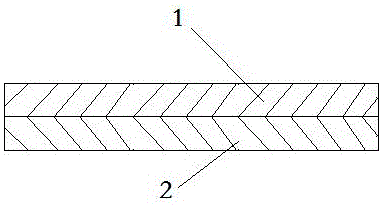

[0015] The composite contact is composed of a silver alloy contact layer 1 and a copper alloy contact layer 2; the silver alloy contact layer 2 accounts for 10% of the thickness of the composite contact.

[0016] The specific composition and weight ratio of the silver alloy contact layer 1: molybdenum 5%, diamond 1%, silver balance.

[0017] The specific composition and weight ratio of the copper alloy contact layer 2: molybdenum 5%, graphite 4%, copper balance.

[0018] Installed on a small residual current protective circuit breaker for form test, test results

[0019] Running break breaking capacity 6 thousand amperes

[0020] Electrical life 3000 times

[0021] Temperature rise <60K after test.

Embodiment 2

[0023] The composite contact is composed of a silver alloy contact layer 1 and a copper alloy contact layer 2; the silver alloy contact layer 1 accounts for 20% of the thickness of the composite contact.

[0024] The specific composition and weight ratio of the silver alloy contact layer 1: molybdenum 15%, diamond 4%, silver balance.

[0025] The specific composition and weight ratio of the copper alloy contact layer 2: molybdenum 10%, graphite 10%, copper balance.

[0026] Installed on a small residual current protective circuit breaker for form test, test results

[0027] Running break breaking capacity 10,000 amperes

[0028] Electrical life 4000 times

[0029] Temperature rise <60K after test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com